- Home

- Automated Lot Trace Solution

- Statistical Process Control

Automated Lot Trace Solution

Statistical Process Control

To help the bakery maintain a high degree of quality control and product consistency as volume increased, Simpli-Baked contacted SG Systems to implement the V5 Formula System / ingredient batching system combined with the V5 Statistical Process Control System / Average Weight System at their AA BRC accredited Bakery, which runs 24/7.

Award winning ‘Simpli-Baked’ produce over 100 million flat bread products a year. All from their high-tech bakery, located in County Offaly, Ireland.

Simpli-Baked was created in 2009 by Niels Ladefoged & Managing Director, Kieran Walsh. Bakers obsessed with quality control and customer service. Two attributes which go together hand in hand when producing such a high volume of tasty tortillas, pizza bases and flatbreads.

SAGE Integrated V5 Ingredient Batching & Traceability

Simpli-Baked required an ingredient batching solution to manage all Stock (Receiving & Shipping), Batch Production & Statistical Process Control (SPC).

The V5 ingredient batching software allows the ingredient and packaging inventory to be managed, labeled, and put away into the storage areas, while observing strict allergen controls and lot FEFO management. V5 Software runs on a regular windows tablet PC with a networked label printer to barcode all inventory.

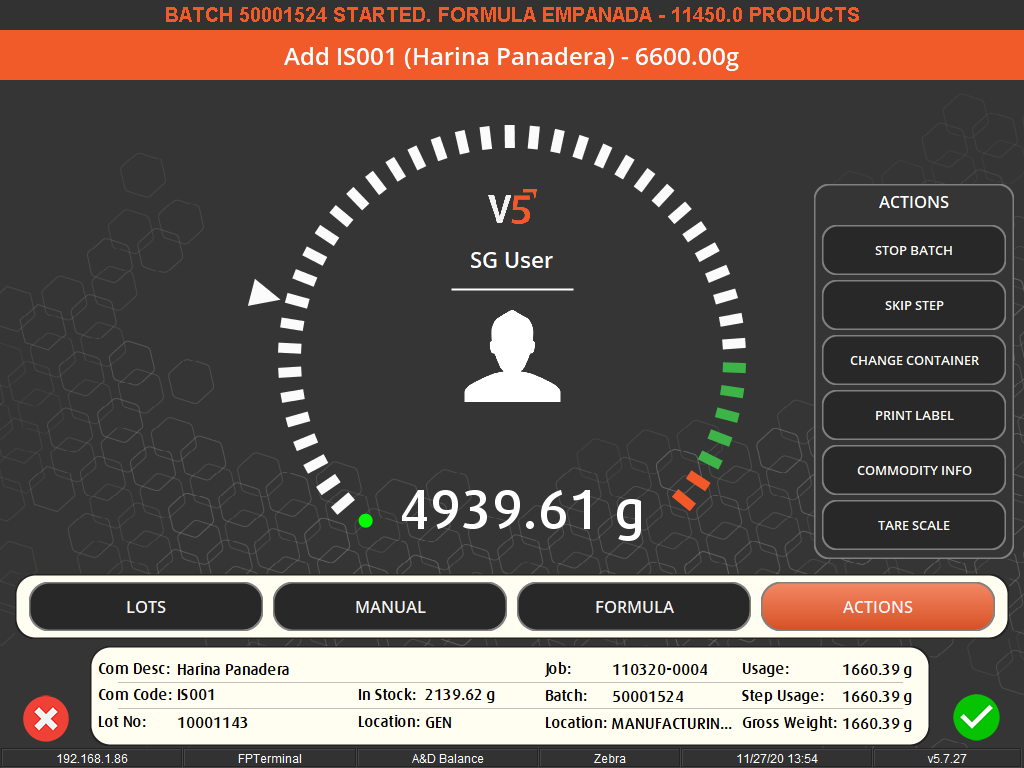

In Production, four V5 Formula System Terminals connect to the local area network ensure the correct ingredients are weighed and batched at the exact quantities. This reduces the opportunity for human errors such as missing ingredients out or adding them at incorrect quantities.

Statistical Process Control / Average Weight System

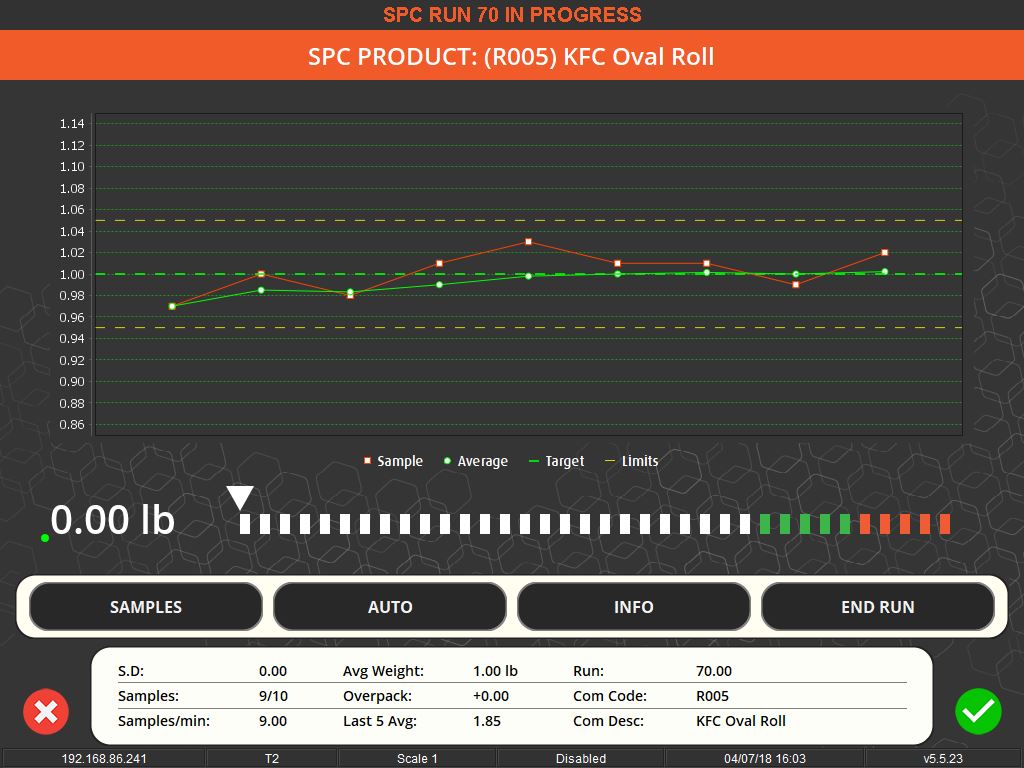

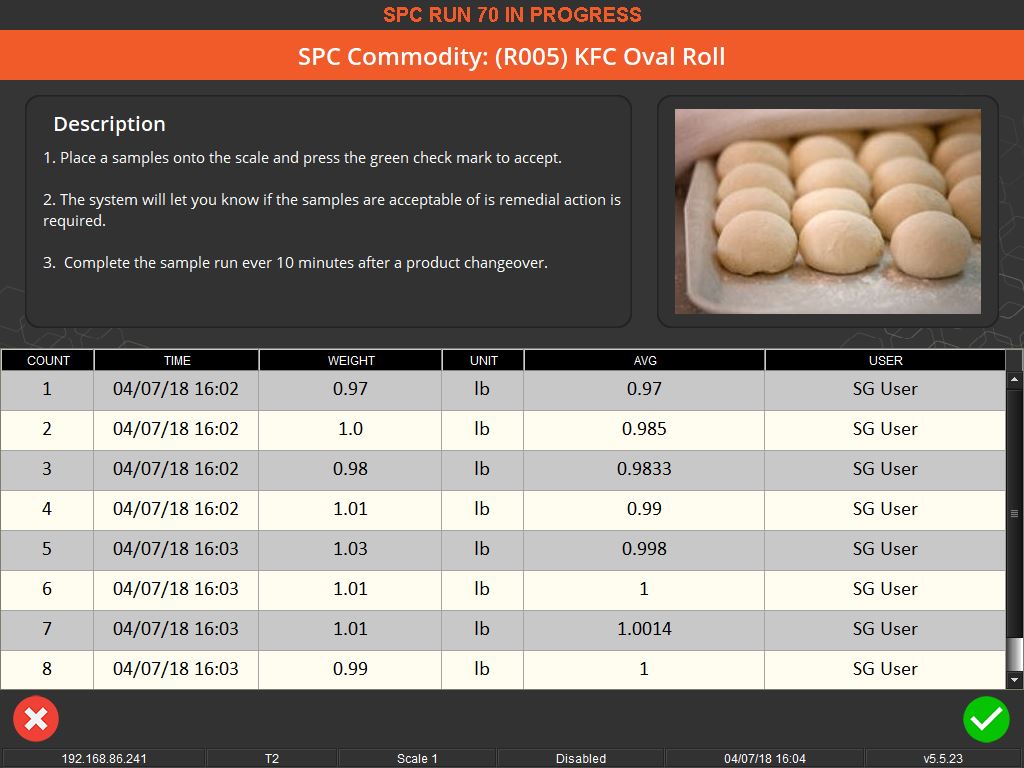

To maintain an accurate and consistent product with regard to size and shape, Statistical Process Control (SPC) is essential. In a food and bakery environment, this involves removing dough balls from the production lines (prior to shaping) and weighing them. The V5 Statistical Process Control System ensures the doughballs are weighed and the weight is recorded against the batch. The average weight system produces on screen feedback for operators alerting them of high or low sample trending which is usually indicative of divider problems which need to be addresses.

After the samples are takes, the count, standard deviation timestamps are logged against the batch number. This process prevents giveaway and detects product inconsistencies for each of the filling heads / divider nozzles.

Managing Director, Kieran Walsh comments “Before we installed V5 Traceability, Simpli-Baked had been working in ‘Excel-hell’ as it became known. We looked at several ingredient batching software solutions before settling on SG Systems. Initially to help implement digital traceability and control of our systems. Once installed, we progressed to integrating with our current SAGE business system to reduce manual data handling between systems. The V5 System is exceptionally powerful”

Behind the scenes on the company’s business server, the V5 Traceability System is keeping electronic records of all production, statistical process control and inventory data. This delivers ingredient batching traceability and minimizes unaccountable errors. Simpli-Baked now has a paperless traceability and quality control system that can be relied on. BRC audits require traceability to meet their strict quality control system.

What is Statistical Process Control?

Also knows an SPC or SQC, Statistical Process Control is the method of quality control which used statistical methods (weighing samples, taking physical dimension etc) to review and therefore control a manufacturing process. SPC ensures production processes operate efficiently, producing tightly managed products with a reduction in food waste and the need to rework batches. SPC ultimately influences the final quality of the product which results in happier customers, reduced product return and improved customer service.

For more information on V5 Traceability, visit www.sgsystemsglobal.com For more information on Simpli-Baked visit www.simplibaked.com

Case Studies Download Section

North America

SG Systems LLC

4101 McEwen #240, Dallas TX 75244

Phone: +1 214 819 9570

Contact us here

United Kingdom

SG Systems Europe Ltd

Suite 3 Walton Summit Centre, Green Place, Four Oaks Rd, Preston, PR5 8AY

Phone: +44 (0) 114 349 1480

Contact us here

Australia

Wedderburn

101 Williamson Road, Ingleburn NSW 2565

Phone: +61 2 9426 1800

Contact us here

Europe

SG Traceability Systems Ltd

31-32 Greenmount Office Park, Harolds Cross, Dublin D6, Ireland

Phone: +44 (0) 114 349 1480

Contact us here

Rest assured, we value your privacy and are committed to keeping your data safe. By clicking "Continue with recommended settings," you're giving us permission to use cookies. Of course, you're in control – feel free to adjust your cookie settings anytime in our Privacy Preferences.