- Home

- Allergen Control

- End To End Traceability for Bakers

Allergen Control

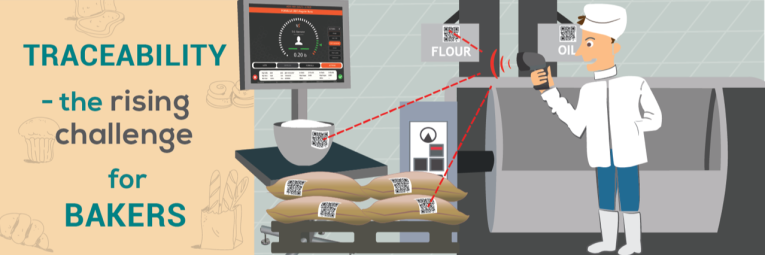

End To End Traceability for Bakers

In the expansive world of baking, understanding the journey of bread, its history, and its evolution is fundamental. Bread baking is an art form that has its roots deep in history, going as far back as the stone age, a staggering 30,000 years ago. This ancient craft witnessed significant advancements during the Roman Empire’s reign, which around 300 BC, revolutionized the commercial baking processes. Bakers were revered in society, considered craftsmen who not only provided sustenance but also added artistic flair to their creations. Today, while the artistry remains intact, the challenges faced by bakers have evolved, especially in the realm of regulatory demands. With regulatory bodies and auditors imposing increasingly stringent traceability requirements, the baker’s role is no longer confined to crafting delightful pastries and loaves. Their profession has morphed into a pivotal societal role, ensuring safety and adherence to standards.

One cannot overlook the impact of media in today’s digital age. High-profile product recalls, frequently showcased in media, have enhanced consumer awareness, emphasizing the paramount importance of traceability. This heightened awareness has prompted retail behemoths such as Wal-Mart, Safeway, and Costco to sit up and take notice. Quick Service Restaurants (QSRs), including global chains like McDonald’s, Burger King, and Wendy’s, are now imposing mandates that require suppliers to have robust traceability solutions, ensuring the safety and authenticity of both commodities and packaging items.

Harnessing the Power of Technology

This comprehensive article will delve deep into how cutting-edge technological advancements are reshaping the bakery industry. Modern bakeries, whether they operate on a commercial, wholesale, retail, or artisanal scale, now possess tools that enable them to sidestep blanket recalls. These advanced solutions ensure that recalls are nuanced, allowing for visibility that covers the entire spectrum of the baking process. This end-to-end traceability solution tracks every stage – from the moment raw materials are received at the bakery to the point the finished product is shipped out.

V5 Traceability: Pioneering in the Domain

A standout in the traceability domain, the V5 Traceability masterfully blends intuitive software with state-of-the-art hardware. This solution is specifically designed to seamlessly connect management-level decisions with on-ground shop floor operations, which are inherently multifaceted. Addressing various processes, it encompasses stages like the receiving of raw materials, precise pre-scaling of minor ingredients, meticulous tracking of bulk ingredients and toppings, accurate finished product labeling, and efficient sales order fulfillment.

But what sets V5 Traceability apart is its real-time communication capabilities. Gone are the days of tedious waits and lags. This networked traceability solution ensures that traceability data is instantly accessible, updated in real-time, ensuring that bakeries can respond swiftly to any discrepancies or demands.

The Intricacies of the Process

1. Inventory Management: A Deep Dive

- Receiving: The traceability journey commences at the Receiving Dock. Each raw material, as it arrives, is meticulously logged into the system. Using advanced devices such as desktops or mobile PCs, each item, whether it’s on a pallet or a case, is assigned a distinct internal lot code. To make the process more user-friendly, a drop-down menu allows the user to select the supplier and the inventory item, streamlining the data entry process. Furthermore, variable data such as the supplier’s specific lot number, expiration dates, and the exact quantity received are diligently entered. This culminates in the printing of a barcoded label, which is affixed to the product, ensuring swift scanning and real-time inventory updates in the future. Even bulk ingredients have a place in this process, with references to specific storage units like silos or tanks.

- QA Queries: Quality assurance is the bedrock of any traceability system. Catering to this need, V5 Traceability allows the receiving clerk to address commodity-specific or broadly based QA questions. This interactive process ensures that every detail, from supplier credentials to allergen information and even transportation specifics, is captured and archived for future scrutiny.

- Stock Movement/Modifications: In the dynamic environment of a bakery, stock relocations are commonplace. V5 Traceability makes this task effortless. By simply scanning the product’s lot code, users can relocate stock. The system also allows for inventory adjustments and captures reasons for such moves. This transparency ensures that the management is always in the loop, understanding the ‘why’ behind every action.

2. Production: The Heart of the Bakery

- Planning: Efficient planning is the linchpin of seamless production. V5 Traceability’s scheduling software is a boon for bakers. It simplifies the intricate task of breaking down master recipes into sub-mix components. With this streamlined tool, users can easily plan batches, push sub-mix recipes to specific production terminals, and ensure that batching recipes are only accessible at the relevant workstations. Integration capabilities further elevate this tool, allowing bakeries to import production schedules from existing software platforms.

- Recipe Creation: The heart and soul of any bakery item lie in its recipe. The V5 Traceability offers a robust recipe formulation system, enabling management to dictate exact recipe specifications. This ensures that every baked item, whether it’s a humble loaf or an intricate pastry, is consistent in taste and texture.

- Mixture Creation: Precision is paramount in baking. To guarantee this, V5 Traceability places a recipe control system in every batching area. This ensures that ingredients are weighed to perfection, with tight tolerances that are enforced by the system. This meticulous approach ensures that every recipe is executed flawlessly.

- Ingredient Management: An essential cog in the traceability wheel is the mixer terminal. This allows bulk ingredients to be tracked in real-time, integrating with PLC systems for a holistic view.

- Rework: In baking, not everything always goes as planned. Sometimes, products need to be reworked. V5 Traceability ensures that even rework is traceable, linking back to the original batch or production line.

- Finished Product: The culmination of the baking process is the finished product. At this stage, the solution allows operators to correlate mixer batch numbers with finished product SKUs. This guarantees that each item can be traced back to its origin. Barcoded labels, imprinted with all relevant details, are then printed, ensuring easy scanning during the dispatch process.

- Dispatching: As the finished products make their way to the dispatching docks, the system shines again. Barcoded labels facilitate the seamless correlation of products with specific sales orders. These details can also be integrated back into existing software solutions for a holistic view.

- Monitoring: Central to V5 Traceability is the central server. This powerhouse collates, archives, and serves as the repository for all traceability data. Whether it’s a raw material, a work in progress, or a finished product, everything is meticulously tracked, ensuring an end-to-end traceability solution.

Final Thoughts: Why V5 Traceability Stands Out

In today’s volatile environment, where recalls can tarnish reputations and erode consumer trust, can you afford to delay integrating a comprehensive traceability solution? V5 Traceability stands poised, ready to guide bakeries through this maze. With a rich legacy, cutting-edge technology, and deep industry knowledge, V5 Traceability is the partner that every bakery needs.

Seeking a deeper understanding or wish to engage with V5 Traceability? Explore www.sgsystemsusa.com for a treasure trove of insights or connect directly by calling (214) 819-9570.

Embarking on the traceability journey has never been more crucial. Are you ready to take the plunge?

North America

SG Systems LLC

4101 McEwen #240, Dallas TX 75244

Phone: +1 214 819 9570

Contact us here

United Kingdom

SG Systems Europe Ltd

Suite 3 Walton Summit Centre, Green Place, Four Oaks Rd, Preston, PR5 8AY

Phone: +44 (0) 114 349 1480

Contact us here

Australia

Wedderburn

101 Williamson Road, Ingleburn NSW 2565

Phone: +61 2 9426 1800

Contact us here

Europe

SG Traceability Systems Ltd

31-32 Greenmount Office Park, Harolds Cross, Dublin D6, Ireland

Phone: +44 (0) 114 349 1480

Contact us here

Rest assured, we value your privacy and are committed to keeping your data safe. By clicking "Continue with recommended settings," you're giving us permission to use cookies. Of course, you're in control – feel free to adjust your cookie settings anytime in our Privacy Preferences.