Weighing Audit Trails

This topic is part of the SG Systems Global manufacturing execution, inventory integrity and batch traceability glossary.

Updated December 2025 • weighing audit trails, GxP electronic audit trail, scale integration, tare/zero events, calibration & verification logs, reason codes, overrides, electronic signatures, Part 11/Annex 11 data integrity, ALCOA+, time sync, record retention, review by exception • Pharmaceutical, Dietary Supplements, Food Processing, Ingredients & Dry Mixes, Cosmetics, Agricultural Chemicals, Plastic Resin, Consumer Products, Bakery, Sausage & Meat Processing, Produce Packing, Medical Devices

In regulated manufacturing, weighing isn’t just a measurement. It’s a decision point: accept/reject, add/hold, release/quarantine, proceed/stop. That’s why Weighing Audit Trails exist. They turn a weight from a “number someone saw” into evidence—evidence you can defend when a batch is investigated, a complaint comes in, or an auditor asks the one question that always matters: how do you know the data is trustworthy?

Weighing Audit Trails are the tamper-evident, time-stamped records of what happened on the scale and around the scale: logins, tare/zero, calibration checks, configuration changes, weight captures, manual entries, overrides, reweighs, and the “why” behind exceptions. When implemented correctly, they establish that a weighing record is attributable (who), contemporaneous (when), legible (readable), original (the real source), and accurate (correct)—the practical backbone of Data Integrity.

At SG Systems Global, we treat Weighing Audit Trails as a shop-floor control, not a compliance checkbox. They are inseparable from Weigh & Dispense Automation, GxP Audit Trails, and the hard reality of production pressure: if your workflow makes it easy to “get the weight” but hard to capture the evidence, the evidence will be missing when you need it most. Conversely, if your system captures weights directly from the instrument and records the surrounding events automatically, audits get simpler, investigations get faster, and operations get tighter.

Here’s the line you should adopt as policy: if the weighing system can produce a weight but cannot produce an audit trail, you do not have controlled weighing. You have a measurement with a story attached.

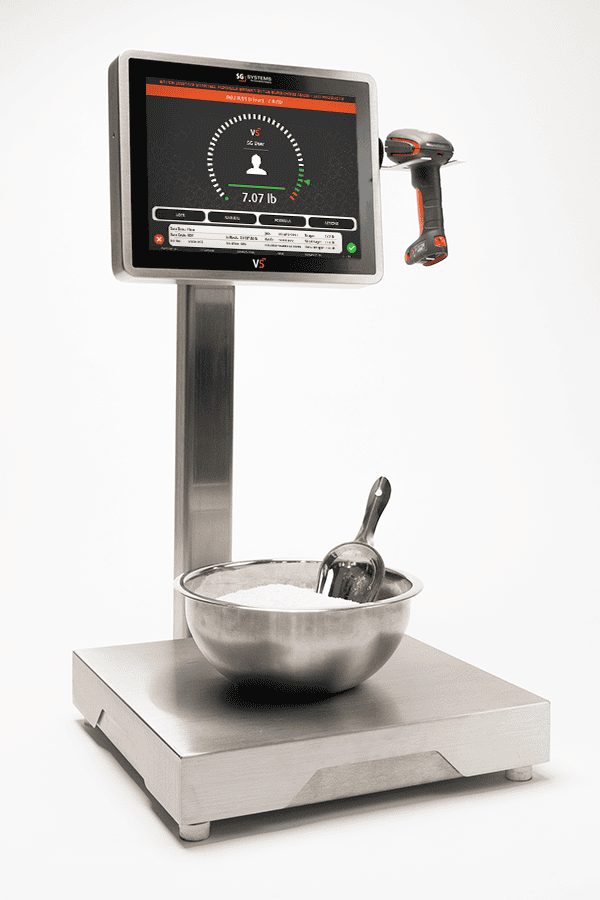

Figure: Audit-ready weighing isn’t just a scale reading. It’s a chain of events (login → tare/zero → verify identity → capture weight → handle exceptions) recorded as time-stamped, tamper-evident transactions.

When weighing audit trails are implemented correctly, you gain four outcomes that matter in the real world:

- Regulatory defensibility. Your weighing records align with electronic records expectations like 21 CFR Part 11 and Annex 11, supported by a complete, computer-generated Audit Trail.

- Data integrity you can prove. You can show who did what, when, and why—especially when a weight is re-entered, corrected, overridden, or captured under exception conditions.

- Operational control. You can detect and prevent “quiet failure modes” like shared logins, repeated reweighs, tolerance shopping, and manual entry habits that look normal until they trigger a deviation.

- Faster investigations and release. With structured events, you can use Batch Review by Exception logic: review the exceptions, not every line item.

“A printed weight is not evidence. Evidence is the weight plus the audit trail that proves how it was produced, who produced it, and how exceptions were handled.”

1) Weighing audit trail stack — what has to be connected

Weighing Audit Trails don’t come from one setting on a scale. They come from a stack of controls that spans instruments, software, identity, workflow, and review. The table below shows what must connect if you want weighing records that survive audits and help operations run tighter.

| Layer | What it controls | Key glossary / system anchors |

|---|---|---|

| Instrument & Metrology | Scale performance, calibration/verification status, resolution, drift, and environmental constraints |

Load Cells & Weighing Systems, Tare Verification |

| Identity & Access | Unique user logins, roles, permissions, and electronic signatures for critical actions |

UAM, 21 CFR Part 11 |

| Workflow Context | Linking weights to the correct work order, step, material, lot, container ID, and location |

Work Order Execution, Material Lot Assignment |

| Data Capture Method | Direct instrument capture vs manual entry; validation rules and rounding behavior |

Weigh & Dispense Automation, V5 Connect API |

| Audit Trail Engine | Computer-generated, time-stamped logs of changes and key events with before/after values |

Audit Trail (GxP), Data Integrity |

| Exception Handling | Reason codes, approvals, overrides, reweighs, substitutions, tolerance breaches |

Hard Gating, Deviation Management |

| Review & Release | Exception-based review, trend detection, and closure to support batch release readiness |

BRBE, Exception-Based Process Review |

| Governance & Retention | Change control, training, retention, backup, time sync, and record availability |

Management of Change, Training Matrix |

2) Why weighing audit trails are a high-stakes control (not an “IT log”)

Weighing sits inside many of the highest-risk operations in manufacturing: dispensing actives, verifying allergens, dosing concentrates, confirming pack counts, performing in-process checks, and reconciling yields. Those activities directly influence safety, quality, compliance, and cost. That’s why auditors don’t treat “the weight value” as the record—they treat the system that produced the weight as the record.

The uncomfortable truth is that most weighing failures aren’t dramatic. They’re quiet:

- Shared logins that erase accountability.

- “One more reweigh” until the number fits the tolerance.

- Manual entry “because the cable was acting up.”

- Configuration drift (rounding rules, units, stability criteria) that changes the meaning of the measurement.

- Time drift that breaks sequence and makes investigation timelines unreliable.

- Local deletion or overwrite of instrument logs.

Without a robust audit trail, these problems show up late—during batch record review, during a customer investigation, or during an audit. With a robust audit trail, they show up early, as measurable exceptions you can correct. That’s the real purpose: prevention through visibility.

3) What a “weighing audit trail” actually is (and what it is not)

A weighing audit trail is a secure, computer-generated, time-stamped record of critical events and changes associated with weighing activities and weighing data. It should capture both data events (weight captured, record saved, record invalidated) and control events (tare, zero, method changes, user changes, overrides).

It is not the same as:

- A printed ticket. Printouts are easy to lose, reprint, or detach from context. They rarely prove identity or intent.

- A spreadsheet log. Spreadsheets can be useful for analysis, but they are weak as primary GxP evidence unless heavily controlled—and most plants do not control them adequately.

- A generic IT system log. Server logs may show “a user logged in,” but not “a tare override occurred on scale 3 at station B during operation 20.”

- A calibration certificate. Calibration proves the instrument was within tolerance at a point in time. The audit trail proves how the instrument was used and how data was handled.

In practical terms, a weighing audit trail answers these questions without debate:

- Who performed the weighing?

- Which instrument was used, and what was its status?

- What item/lot/container was weighed?

- When did it happen, and in what sequence relative to process steps?

- How was the value captured (instrument capture vs manual entry, stable weight criteria, rounding)?

- Why were any exceptions, changes, or overrides executed?

4) The critical events that should appear in a weighing audit trail

If your audit trail captures only “weight saved,” you’re missing the story. The “story” is exactly what regulators and customers care about because it’s where risk lives. Below is a practical list of critical events you should expect in an audit-ready weighing environment:

| Event category | Examples | Why it matters |

|---|---|---|

| User & session | Login, logout, user switch, failed login, role changes | Proves accountability; detects shared credentials and unauthorized access |

| Instrument state | Scale connected/disconnected, stability status, warmup, overload, error states | Explains questionable readings and prevents “ghost weights” |

| Tare/zero & container | Zero, tare, tare change, container ID association, tare verification pass/fail | Most dosing errors start with wrong tare or wrong container |

| Method/config changes | Units change, rounding change, tolerance setpoint change, stability criteria change | Configuration drift changes the meaning of the measurement |

| Data capture | Weight captured (gross/tare/net), manual entry, reweigh, invalidate/reverse | Shows how the value entered the record and whether it was manipulated |

| Exceptions & overrides | Out-of-tolerance accept, limit override, bypass identity confirmation, step skip | These are the “high-risk decisions” that must have reason and approval |

| Approvals & e-sign | Second-person verification, electronic signature on exception acceptance | Proves governance, especially for critical additions and deviations |

| Integration & transmission | Data sent to MES, acknowledgement received, resend attempts, message errors | Prevents “the scale showed it, but the system didn’t get it” disputes |

The point is not to log everything. The point is to log what creates risk: identity, configuration, exceptions, and data handling.

5) Minimum data fields for defensible weighing audit trails

A robust weighing audit trail needs a consistent event model. You don’t want “free text” logs that are impossible to review. You want structured, reviewable events with consistent fields. At minimum, each event should include:

- Event type: e.g., weight capture, tare, override, config change, login.

- Timestamp: secure, time-synchronized time; ideally with time zone consistency across systems.

- User identity: unique user ID (no shared accounts), with role.

- Instrument identity: scale ID/serial, station/location, integration endpoint.

- Context: work order, operation/step, product/formula, equipment/vessel/line (where applicable).

- Material context: item ID, lot, container ID, barcode scan result (when relevant to dispensing).

- Value fields (when relevant): gross/tare/net, UoM, resolution, stability flag, rounding applied.

- Before/after values: for any change event (e.g., tolerance changed from X to Y).

- Reason code: structured reason for exceptions/changes (not “other” by default).

- Approval evidence: second-person verification or e-signature metadata for governed actions.

- System evidence: application version, configuration version, and audit trail record ID (for traceability).

This is where “audit trail” becomes practical. With consistent event fields, you can answer audit questions quickly and run analytics (trend overrides, find repeated reweigh patterns, flag manual entry habits). Without structure, you’re stuck doing forensic text searches.

6) Data integrity reality: the audit trail’s job is to prove ALCOA+ without heroics

Most plants can recite ALCOA. Fewer can prove it. A weighing audit trail is one of the most direct ways to prove data integrity because it sits at the moment data is created.

What a “good” weighing audit trail does for ALCOA+ in practice:

- Attributable: unique logins; the audit trail records who performed and who approved.

- Legible: records are readable, consistent, and available in human review format.

- Contemporaneous: the timestamp is automatic and reliable; no “written later.”

- Original: the weight originates from the instrument capture, not a retyped number.

- Accurate: stability criteria, rounding rules, and tare controls are enforced and recorded.

- Complete & consistent: the audit trail shows changes, invalidations, and reweighs—not just final values.

- Enduring & available: records are retained and retrievable for the required period, even after system upgrades.

This is also why time synchronization matters. If a scale’s clock is off by 12 minutes, you can’t reliably reconstruct sequence. In a deviation, sequence is everything.

7) Part 11 / Annex 11 in plain language: what your weighing audit trail must support

Plants often treat Part 11 and Annex 11 as “IT compliance.” That’s a mistake. For weighing systems, these expectations show up as operational requirements:

- Security & access control. Only authorized users can perform actions; privileges align to roles (UAM).

- Computer-generated, time-stamped audit trails. The system records changes and critical events automatically, and users cannot disable or edit the audit trail.

- Record accuracy and completeness. You can produce accurate and complete records for inspection (not “we can’t export that”).

- Electronic signatures (when used). If you accept an out-of-tolerance weigh or approve an override, the signature has meaning and is linked to the record.

- Procedural controls. Training, SOPs, and governance support the system controls (Training Matrix).

- Change control. Updates to methods, tolerances, or software are controlled and documented (MOC).

The practical takeaway: the audit trail is not a file you keep “just in case.” It is part of the control mechanism that makes your weighing records valid.

8) Architecture options: instrument audit trails vs centralized audit trails

Weighing audit trails can live in different places. The wrong approach is to assume the instrument’s built-in log is enough. Sometimes it is, but often it isn’t—especially when you need workflow context.

Common architecture models:

- Instrument-only logs. The scale stores events locally. This can work for standalone operations, but retrieval, retention, and context linkage are typically weak.

- PC-based weighing software logs. The workstation captures events and writes audit logs. Better context, but still vulnerable if the workstation is unmanaged or if local storage is not governed.

- Centralized MES/dispensing system logs. The application captures instrument data and writes a centralized audit trail tied to work orders and steps. This is the most defensible approach for regulated production.

- Hybrid approach. Instrument logs are retained for metrology evidence, while the MES captures workflow and data-handling events for batch record defensibility.

Most plants end up hybrid because instrument logs are useful for service and calibration investigations, while MES/QMS context is required for batch-level traceability and governance.

9) How weighing audit trails fail in the real world

Here are the failure modes we see repeatedly across regulated and high-consequence industries:

- Shared credentials. The audit trail says “Operator” did everything. That’s not attributable data.

- Local admin access on weighing stations. People can change settings, delete logs, or install “helper tools.” That’s a data integrity risk.

- Manual entry normalized. If manual entry is common, it becomes a blind spot. Manual entry must be rare, governed, and visible.

- “Final value only” retention. Reweighs, invalidations, and adjustments disappear, so the record looks perfect while reality wasn’t.

- No reason codes. Overrides happen with “N/A” reasons. That’s equivalent to “no control.”

- Instrument time drift. Records can’t be sequenced reliably across scales and systems.

- Uncontrolled configuration changes. Tolerances or rounding rules change without MOC and without audit trail evidence.

- Audit trail not reviewed. You have data, but you don’t use it, so problems accumulate until an audit forces attention.

- Paper fallback without governance. “We wrote it down” becomes the default when integration fails, and the audit trail never shows the gap.

If you recognize any of these, the fix is not “be more careful.” The fix is to harden the workflow so the compliant path is the easiest path.

10) Hard gating on weighing actions: the controls that prevent bad data

Weighing audit trails become powerful when they’re paired with Hard Gating. The audit trail tells you what happened; hard gates prevent the wrong thing from happening in the first place.

| Risk event | What the system should do | What the audit trail captures |

|---|---|---|

| Manual weight entry attempted | Block by default or require second-person verification | Attempt + reason + approver + final disposition |

| Out-of-tolerance weight | Block, force reweigh, or route to governed override | Measured value + tolerance + action taken + reason |

| Scale not verified / overdue | Prevent use; require qualified instrument | Block event + instrument status + user attempted action |

| Wrong container / tare mismatch | Block capture; require tare verification | Container ID + tare expected vs observed + resolution |

| Configuration change attempt | Restrict to authorized roles and require MOC linkage | Before/after values + who + why + approval evidence |

| Identity confirmation failure | Block or route to controlled exception workflow | Scan result + mismatch details + override path used |

Tell it like it is: if operators can bypass controls quietly, your audit trail becomes a list of regrets. If you gate the risks, the audit trail becomes proof of control.

11) Time synchronization: the detail that makes or breaks investigations

Weighing audit trails live and die on timestamps. In practice, you need:

- Consistent time sources across scales, workstations, and servers (commonly NTP).

- Time zone governance for multi-site operations so sequences are interpretable.

- Auditability of time changes: if a device’s clock changes, that change should itself be recorded.

- Sequence integrity: ability to reconstruct “what happened first” across steps.

Audits and investigations become painful when time cannot be trusted. It’s a solvable problem—if you treat it as a control requirement, not a convenience setting.

12) Review by exception: how to actually use weighing audit trails

Audit trails are only valuable if they are reviewable and reviewed. The modern approach is not to read every event—it’s to define what counts as an exception and review those exceptions consistently. This aligns directly with BRBE principles.

Practical “weighing audit trail exceptions” worth reviewing:

- Manual entry events (especially repeated by the same user or station).

- Out-of-tolerance events and overrides (including “accepted OOT”).

- Repeated reweighs for the same target (tolerance shopping patterns).

- Tare changes after a first weight capture (potential manipulation).

- Configuration changes (rounding, tolerances, units, stability criteria).

- Scale disconnects or error states during capture windows.

- Use of instruments that are overdue for verification or in a questionable status.

- Identity confirmation bypasses or mismatches (wrong lot attempts).

When you capture these as structured events, review becomes fast and defensible: you can show what you look for, how often you look, and what actions you took. That’s how audit trails become operational controls rather than compliance baggage.

13) Why weighing audit trails and material consumption recording are inseparable

In many processes, the “consumption” quantity is the net weight captured at dispense or charge. If the weighing record is weak, the consumption record becomes weak. That’s why weighing audit trails are a foundational component of Material Consumption Recording.

Consider what happens when you don’t have weighing audit trails:

- You cannot prove whether a weight was captured from the scale or typed.

- You cannot prove whether a tare was verified or “assumed.”

- You cannot prove whether an out-of-tolerance event was caught and handled properly.

- You cannot prove whether the correct lot and container were used at the moment of weighing.

That cascades into inventory, yield, and genealogy problems. With robust audit trails, your consumption records become evidence instead of estimates.

14) Industry realities: where weighing audit trails matter most

Weighing audit trails are valuable everywhere, but the “risk hotspots” vary by industry:

Pharmaceutical Manufacturing (industry overview): weighing often controls potency, uniformity, and batch legality. Audit trails support defensible electronic batch records and show that exceptions were governed—not hidden.

Dietary Supplements (industry overview): micro-ingredients and label claims make dosing errors expensive. Audit trails help distinguish process variability from poor weighing discipline and expose manual-entry culture early.

Food Processing (industry overview): allergens and mass balance turn weighing into recall risk. Audit trails provide evidence for ingredient additions and help prove segregation and correctness when customers challenge you.

Ingredients & Dry Mixes (industry overview): powder handling increases loss and rework loops. Audit trails help prevent “silent compensation” where operators tweak weights to “make it work” without documenting the variance drivers.

Cosmetics (industry overview): consistency and complaint investigations hinge on accurate additions. Audit trails strengthen your ability to isolate whether variability came from formulation, weighing, or upstream raw materials.

Agricultural Chemicals (industry overview): potency adjustments and hazardous materials increase both safety and compliance stakes. Audit trails ensure overrides and corrections are governed and reviewable.

Plastic Resin (industry overview): masterbatch and additive dosing can be automated, but audit trails are still needed to prove configuration control and exception handling when feeders drift or lots change.

Consumer Products (industry overview): high SKU variety means more changeovers and more opportunity for method drift. Audit trails expose when settings change outside controlled processes.

Bakery (industry overview): moisture and ingredient variability create constant temptation to “fix it on the fly.” Audit trails make those adjustments visible and support disciplined process improvement.

Sausage & Meat (industry overview): catch-weight and variable inputs demand accurate weight capture. Audit trails help differentiate real raw variability from data handling issues.

Produce Packing (industry overview): weighing often drives pack-out accuracy and label control. Audit trails support defensible records when weight-driven claims or disputes arise.

Medical Devices (industry overview): adhesives, coatings, and critical components often rely on controlled dispensing. Audit trails support traceability and investigation readiness.

The theme is consistent: wherever weighing is used to decide whether a product is acceptable, the audit trail becomes part of the product’s quality story.

15) System architecture: why “just the scale” or “just ERP” is not enough

In mature environments, weighing audit trails are not isolated. They sit inside the MES/WMS/QMS ecosystem:

- MES provides process context (work order, step, target, tolerance) and captures events in a structured way for batch records.

- WMS provides inventory truth (which lot/container should be at the station), supporting identity verification and preventing wrong-lot weighing.

- QMS provides governance for exceptions (deviations, investigations, CAPA), turning audit trail anomalies into controlled actions.

- ERP may receive results for financial posting, but it is not built to be the primary evidence system for shop-floor weighing.

If your architecture forces operators to weigh in one place and record in another, you’re creating a data integrity gap. The safest architecture is the one where the weight value and its audit trail are captured at the same moment, from the same controlled workflow.

16) How V5 supports weighing audit trails in practice

SG Systems Global’s V5 platform supports Weighing Audit Trails by capturing weighing events as structured, time-stamped transactions tied to work execution—so weights aren’t just recorded; they’re controlled.

- V5 MES. The V5 MES layer:

- Links weighing activity to work orders and recipe steps, enforcing targets and tolerances.

- Captures events (tare, capture, reweigh, override) with context (step, material, lot, container ID).

- Enables exception-driven review aligned with BRBE.

- Applies hard gating where risk is highest (manual entry, OOT accept, wrong-lot attempts).

- V5 WMS. The V5 WMS layer:

- Supports lot/container control and directed material selection, strengthening identity verification during dispensing.

- Improves inventory accuracy by aligning staged inventory with consumption and weighing events.

- V5 QMS. The V5 QMS layer:

- Routes weighing exceptions into governed workflows (Deviations, Nonconformances) instead of invisible adjustments.

- Supports investigation traceability by linking exception events back to underlying audit trail records.

- V5 Connect API. The V5 Connect API:

- Integrates scales, scanners, label printers, and shop-floor devices so weights are captured electronically rather than typed.

- Supports reliable data transmission and error visibility so “missing weights” become detectable exceptions, not hidden gaps.

For the broader manufacturing execution context, see V5 Solution Overview and the cross-industry hub at Industries.

17) KPIs that prove your weighing audit trails are working (or expose that they aren’t)

Good metrics make audit trails operational. These KPIs are practical and hard to game:

- Manual entry rate. % of weights recorded via manual entry vs instrument capture (manual should trend toward near-zero).

- Override frequency. Overrides per 100 weigh events, by station, product, and user (spikes = process or culture issues).

- Reweigh density. Average number of reweighs per target weigh event (high values suggest tolerance shopping or unstable methods).

- Out-of-tolerance event rate. OOT occurrences by component and step (helps drive root cause).

- Tare change anomalies. Tare changes after capture or repeated tare changes in short time windows.

- Scale downtime & disconnects. Count and duration of disconnect/error states during production windows.

- Time drift alerts. Devices out of acceptable time sync window.

- Audit trail review closure time. Time from exception occurrence to documented review/closure.

- Unauthorized attempt rate. Blocked actions due to role restrictions (good indicator that gates work).

- Configuration change count. Changes per month, each linked to approved change control.

If you can’t measure these, you’re not using your audit trail as a control mechanism—you’re just storing it.

18) Common pitfalls: why plants think they have audit trails, but don’t

- “The scale prints a ticket.” Printouts are not secure audit trails. They rarely capture who/why/changes.

- “The scale has a log.” Instrument logs may lack workflow context and may be hard to retrieve/retain reliably.

- “We review when there’s a problem.” That’s not review; that’s forensics. Audit trails should support routine exception review.

- Shared accounts on dispensary PCs. This destroys attributable data and invites ungoverned changes.

- Manual entry as a workaround. If integration isn’t reliable, manual entry becomes the norm, and data integrity erodes.

- No before/after values. If a tolerance or target changes, the audit trail must show what changed.

- Weak reason codes. “Other” is not a reason code. It’s an avoidance mechanism.

- No governance for configuration. If methods/units/rounding can be changed without MOC, the measurement definition is unstable.

- Time drift ignored. If timestamps can’t be trusted, sequence-based investigations become guesswork.

- Audit trail retention not engineered. If logs aren’t retained through upgrades and workstation replacements, you’ll fail when asked for historical evidence.

19) Quick-start checklist: strengthening weighing audit trails in 30–60 days

- Inventory your scale fleet (models, firmware, interfaces, locations) and define which use cases are GxP-critical.

- Eliminate shared logins at weighing stations; enforce unique user IDs and role-based permissions (UAM).

- Define critical weighing events that must be audited (tare/zero, capture, manual entry, overrides, config changes).

- Integrate scales where feasible so weights are captured electronically (V5 Connect API) rather than typed.

- Disable or govern manual entry: if it must exist, require reason code and second-person verification.

- Implement time synchronization (NTP) and define acceptable drift thresholds; audit and alert on time changes.

- Enforce container/tare controls for dispensing stations (Tare Verification & Container Control).

- Implement hard gating for out-of-tolerance capture and wrong-lot attempts during dispensing.

- Standardize reason codes for overrides and exceptions and train operators on when to use each.

- Route significant weighing exceptions into Deviation Management workflows instead of “fixing the record.”

- Define an exception review cadence and ownership (daily/shift-based for high-risk stations).

- Validate record retention and retrieval: prove you can pull a complete audit trail for a batch and a station quickly.

- Lock down workstation admin privileges; treat weighing stations as controlled assets.

- Put configuration under change control (MOC) and record before/after changes in the audit trail.

- Define “integration failure” handling: if the scale can’t transmit, the system should create an exception record automatically.

- Align SOPs and training with system behavior (Training Matrix).

20) Weighing Audit Trails FAQ

Q1. Is a printed scale ticket an audit trail?

Not by itself. A ticket is a piece of output. An audit trail is a secure, time-stamped record that captures key events and changes—who captured the weight, how it was captured, and why exceptions were accepted or changes were made.

Q2. What’s the single biggest red flag in weighing audit trails?

Routine manual entry. Manual entry can be allowed for true exceptions, but it should be rare, visible, and governed with reason codes and (often) second-person verification.

Q3. Do we need to audit tare and zero events?

Yes for controlled environments. Many of the most damaging weighing errors come from tare misuse or container misidentification. Audit trails should capture tare/zero events and, where applicable, tare verification outcomes.

Q4. Should audit trails capture reweighs and invalidations?

Absolutely. If only the final value is kept, you lose the evidence needed to detect tolerance shopping, unstable methods, and data handling manipulation. Reweighs and invalidations are the exact events audit trails are meant to expose.

Q5. Can we rely on the scale’s internal log for compliance?

Sometimes, but usually not alone. Instrument logs often lack batch/work-order context and can be difficult to retrieve and retain reliably. A centralized system that captures instrument data and workflow context is typically more defensible.

Q6. How do weighing audit trails speed batch release?

They enable exception-based review. When audit trail events are structured and tied to the batch, reviewers can focus on manual entries, overrides, OOT events, and configuration changes—rather than re-checking every normal weigh line.

Related Reading

• Industries: Industries Hub | Pharmaceutical Manufacturing | Dietary Supplements | Food Processing | Ingredients & Dry Mixes | Cosmetics | Agricultural Chemicals

• Products: V5 MES | V5 WMS | V5 QMS | V5 Connect API | V5 Solution Overview

• Glossary: Weighing Audit Trails | Audit Trail (GxP) | Data Integrity | 21 CFR Part 11 | Annex 11 | Weigh & Dispense Automation | Tare Verification & Container Control | Hard Gating | BRBE

OUR SOLUTIONS

Three Systems. One Seamless Experience.

Explore how V5 MES, QMS, and WMS work together to digitize production, automate compliance, and track inventory — all without the paperwork.

Manufacturing Execution System (MES)

Control every batch, every step.

Direct every batch, blend, and product with live workflows, spec enforcement, deviation tracking, and batch review—no clipboards needed.

- Faster batch cycles

- Error-proof production

- Full electronic traceability

Quality Management System (QMS)

Enforce quality, not paperwork.

Capture every SOP, check, and audit with real-time compliance, deviation control, CAPA workflows, and digital signatures—no binders needed.

- 100% paperless compliance

- Instant deviation alerts

- Audit-ready, always

Warehouse Management System (WMS)

Inventory you can trust.

Track every bag, batch, and pallet with live inventory, allergen segregation, expiry control, and automated labeling—no spreadsheets.

- Full lot and expiry traceability

- FEFO/FIFO enforced

- Real-time stock accuracy

You're in great company

How can we help you today?

We’re ready when you are.

Choose your path below — whether you're looking for a free trial, a live demo, or a customized setup, our team will guide you through every step.

Let’s get started — fill out the quick form below.