Batching Scale Software — Automated Recipe Control, Multi-Scale Weighing & Traceable Lots

This topic is part of the SG Systems Global regulatory & operations glossary.

Updated November 2025 • batching scale software, batching control system, gain-in-weight / loss-in-weight batching, sequence control, tolerance enforcement, data integrity, traceability • Food, Dietary Supplements, Pharma, Cosmetics, Chemicals, Meat & Sausage, Bakery, Plastic & Resin, Ingredients & Dry Mixes

Batching Scale Software is the control layer that turns a collection of silos, feeders, floor scales, micro-dosing hoppers and flow meters into a coherent automatic batching system. It knows the formula, selects the right feeders and scales, sequences additions, enforces tolerances, and records what really happened—down to the gram and lot—for every batch. It closes the gap between ERP/MES plans and shop-floor reality, while creating defensible records for BMR/eBMR, audits, and recalls.

In plants that rely on gain-in-weight vs loss-in-weight feeding, high-capacity silos and micro-ingredient stations, Batching Scale Software makes sure each automatic batch is truly under control—not just “near enough” until something fails in the field.

“If your automatic batching can’t show which feeder, which lot, which setpoint, which tolerance, which actual weight, which time—you don’t have control. You have automation and hope.”

1) Why Batching Scale Software now—hard truths

- Automatic doesn’t mean traceable. PLC-based batching often runs for years with no reliable, batch-level record of which lots, what actual weights, and which feeders were involved.

- One tolerance does not fit all. Applying the same scale tolerance to salt, enzymes, APIs, pigments and nitrite is lazy and dangerous. Tolerances must be ingredient-specific and hard-enforced.

- “Setpoint only” is not evidence. A recipe table in the PLC is not proof of what was delivered; actual delivered mass, ramp profiles and deviations need to be recorded.

- Data integrity violations often start in black-box controllers. Standalone batching PLCs with no user IDs, no audit trails, and no secure backups are increasingly unacceptable under data-integrity and GFSI expectations.

- Mass balance and yield analysis require real weights. Without accurate, stored weights, you cannot meaningfully reconcile inputs vs outputs or attack loss and rework.

2) Scope of Batching Scale Software

| Area | What it controls | Glossary anchors |

|---|---|---|

| Formula & Recipe Control | Targets, tolerances, feeders/scales per ingredient, order of addition | Products & Formulas, BOM |

| Feeder & Scale Mapping | Which ingredients run from which silos, hoppers, micro stations, floor scales | Load Cells & Weighing Systems |

| Gain-in-Weight / Loss-in-Weight | Feeder modes, ramp profiles, cutoff strategy, dribble/feed logic | Gain-in-Weight vs Loss-in-Weight Feeding |

| Material Identity | Lot assignment to silos/hoppers, barcode validation at source, FEFO rules | Material Identity Confirmation, FEFO |

| Tolerance & Interlocks | Per-ingredient tolerance bands, over/under logic, hard gating, exception paths | Hard Gating, Control Limits |

| Calibration & Status | Scale IDs, calibration dates, check weight results, blocking of out-of-tolerance devices | Calibration Status |

| Batch Records & Genealogy | Delivered amounts per ingredient, feeder, time; links to batches and lots | Batch Weighing, Lot Traceability |

| Allergens & Zoning | Line zoning, product sequencing, changeover verification for high-risk feeders | Allergen Control |

| Rework & Reuse | Rework lot additions through feeders, reclaim limits, impact on yield | Rework Traceability, Mass Balance |

| Data Integrity & Audit | Users, roles, e-signatures, audit trails, time sync, long-term retention | Part 11, Audit Trail |

| Integrations | Connections to MES, WMS, ERP, SCADA/PLC, LIMS | MES, WMS |

3) Formula-to-feeder mapping—not all ingredients are created equal

Batching Scale Software starts with a clean mapping between formulas and physical equipment. Each ingredient is associated with one or more silos, bulk tanks, feeders or scales, with priorities and limits. The system knows, for example, that sugar is delivered from Silo 2 via a gain-in-weight hopper on Scale A; enzyme blend from micro station M3 on a precision scale; and brine from Tank 5 via a mass flow meter. This mapping is under Document Control and Change Control, not tweaked ad-hoc in PLC code.

4) Material identity & lot mapping—know what’s in your silos and hoppers

For traceability to mean anything, Batching Scale Software must know which lot is loaded into which silo or feeder at which time. That means:

- Lot-to-silo assignments. When a silo, hopper or feeder is filled, operators scan or enter lot IDs (often via GS1-128 intake labels). The system applies FEFO rules and prevents mixing incompatible lots where prohibited.

- Status and QA hold. Lots on QA hold or expired are blocked from being loaded or used; the software ties into Hold/Release controls in QMS/LIMS.

- Top-ups and cross-batches. Where top-ups or multiple lots in a silo are unavoidable, the system records contribution per lot, so downstream batches can see actual lot splits.

5) Gain-in-weight vs loss-in-weight—how the batch is actually built

Different plants use different strategies for automated dosing:

- Gain-in-weight batching. Ingredients drop into a shared hopper on a scale; the system sequences feeders, watching hopper weight increase to each target plus cut-off. This is typical for many food and dry-mix lines.

- Loss-in-weight feeders. Ingredients are fed from individual hoppers on load cells; the system monitors weight loss to determine delivered mass. This is common for resins, agricultural chemicals and high-throughput lines.

- Hybrid approaches. Liquids may be metered via flow meters into a hopper that is also on a scale; micro-ingredients may be hand-tipped but confirmed by the batching scale software via weight.

Batching Scale Software encapsulates all of this logic in configurable profiles, logging actual delivered mass, ramp/overshoot behavior and alarms per ingredient.

6) Tolerances, interlocks & hard gating—no silent overshoot

Batching Scale Software enforces control, not just automation:

- Ingredient-specific tolerance bands. Set minimum/maximum limits per ingredient; define asymmetric limits where over-delivery is higher risk than under-delivery (or vice versa).

- Approach and cut-off strategy. Use fast-feed/dribble-feed logic to minimize overshoot; record overshoot and apply batch variance rules for investigation if repeated.

- Hard gating of out-of-spec additions. If delivered mass is outside tolerance, the batch step is flagged and subsequent processing is blocked or forced into a controlled deviation path.

- Scale faults and alarms. Load-cell errors, communication faults or stability issues are treated as process deviations, not informational messages, and recorded in the audit trail.

7) Calibration & verification—only qualified scales may batch

Every scale and feeder in the batching network is treated as a GxP-relevant asset:

- Calibration status enforcement. If calibration status is overdue or a verification has failed, the software blocks batching on that device.

- Check weights and verification logs. Routine checks (e.g., start-of-shift, weekly) are captured inside the system with results and action limits.

- IQ/OQ/PQ traceability. Equipment qualification documents and parameters are tied to device configuration under the Validation Master Plan.

8) Allergens, zoning & sequence control

For food, meat, bakery and some cosmetics, allergen control and zoning must reach into the batching system:

- Feeder zoning. Assign feeders (e.g., nut, dairy, gluten) to specific zones; Batching Scale Software prevents incompatible non-allergen formulas from running on allergen-dedicated feeders without documented changeover.

- Sequence rules. Enforce production sequences (e.g., non-allergen → allergen, not the reverse) and flag violations for QA review.

- Cleaning verification. Integrate Allergen Changeover Verification records (checklists, swabs) into the batching workflow before allowing new product families.

9) Genealogy, mass balance & yield

Batching Scale Software is the primary source of truth for ingredient consumption:

- Per-ingredient consumption history. For each batch, the system stores delivered mass per ingredient, feeder and time, supporting lot genealogy and cost analysis.

- Mass-balance checks. Inputs from batching are reconciled with downstream yields, rework and waste under mass balance logic.

- Rework usage. When rework is dosed via feeders, its lot identity, composition and limits are tracked and analysed for long-term impact on quality and yield.

10) Data integrity & audit trails

Because Batching Scale Software holds primary GxP data, it must be fully aligned with data integrity guidance and ALCOA+ principles:

- Unique users & roles. Operators log into batching workstations with individual accounts; permissions control who can change recipes, tolerances or device assignments.

- Comprehensive audit trails. Recipe changes, tolerance edits, device reassignments, override actions and re-batches are captured in audit trails with who/what/when/why.

- Time synchronisation. Batching timestamps are aligned with MES, LIMS and WMS so event sequences are reconstructable and defensible.

- Retention & archival. Batch data is retained and accessible for the full regulatory or customer-defined period under Record Retention & Archival policies.

11) Implementation playbook—evolving from PLC code to Batching Scale Software

- Inventory your batching assets. List all silos, hoppers, feeders, scales and associated PLCs; map which products use which equipment.

- Stabilise formulas and tolerances. Bring BOMs under control, set per-ingredient tolerance bands and define gain/loss-in-weight strategies.

- Connect one line. Start by integrating Batching Scale Software with a single high-impact line; prove genealogy, mass balance and QA review improvements.

- Wire identity and status. Integrate with WMS/ERP for lot and QA status; ensure only released lots are allowed into feeders.

- Roll-out & harmonise. Extend to other lines/plants and retire local PLC “tweaks” so batching behaves consistently across the network.

12) How people search for this (and what we cover)

Teams often look for batching scale software, automatic batching control system, gain-in-weight batching, loss-in-weight controller, multi-scale batching, Part 11 batching, GFSI-ready batching, or MES-integrated batching scales. This page covers all of those: how to control silos, feeders and scales as a single, traceable batching system that holds up in audits and improves yield.

13) How this maps to V5 by SG Systems Global

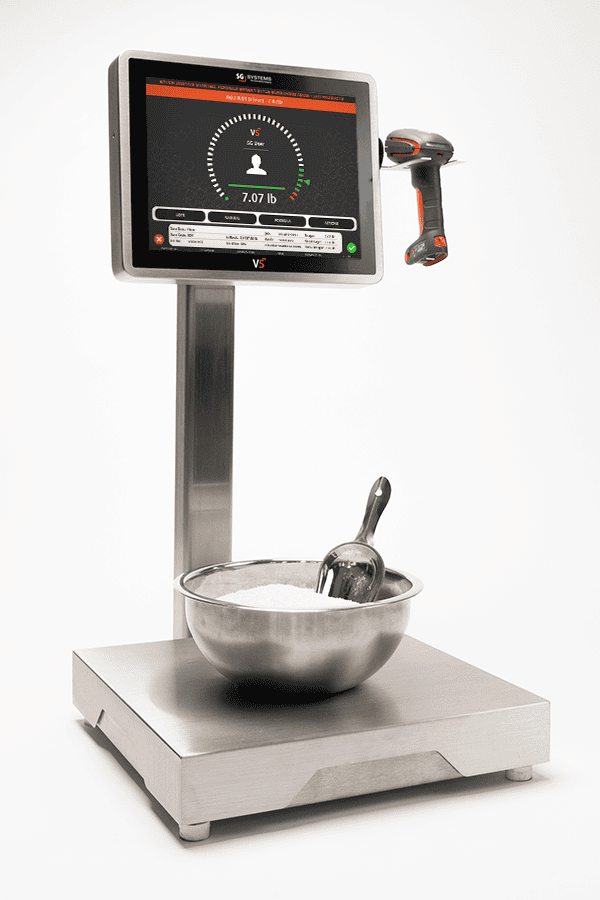

V5 Batching Scale Software sits inside the V5 execution platform as the automation and records layer for multi-ingredient batching:

- With V5 MES. V5 MES provides formula management, step sequencing and eBMR; the batching engine enforces targets and captures actuals.

- With V5 WMS. V5 WMS drives lot-to-silo assignments, FEFO rules and consumption posting back to inventory and traceability.

- With V5 QMS. V5 QMS manages deviations when tolerances are exceeded, or equipment status is violated, and feeds CAPA and trend analysis.

- With V5 Connect API. The V5 Connect API integrates batching data with ERP, LIMS and SCADA/PLC layers, avoiding isolated islands of automation.

See the bigger picture in the V5 solution overview.

14) KPIs that prove Batching Scale Software is delivering

- Right-first-time batches: % of batches that complete automatically with all ingredients within tolerance.

- Tolerance exceptions per 100 batches: frequency of out-of-spec additions requiring QA review.

- Scale/feeder calibration compliance: % of batch additions executed on in-calibration devices (target 100%).

- Manual adjustment rate: proportion of ingredients that require manual top-up or re-batching.

- Mass-balance closure: % of batches where planned vs actual usage reconciles within defined thresholds.

- Time to root-cause for a batch issue: average time to identify which feeder/lot/tolerance caused a problem.

15) Common pitfalls

- Leaving batching logic in undocumented PLC code. Changes are made “on the fly” with no link to MBRs or QMS.

- Treating all ingredients the same. Using generic tolerances and feed profiles regardless of potency or risk.

- No link to lot identity. Silos and feeders are treated as anonymous, making true genealogy impossible.

- Ignoring calibration and verification. Devices with overdue or failed calibrations are used because “they still read.”

- Partial integration. Batching data never reaches MES, WMS, LIMS or ERP; QA and finance have to guess at what really happened.

16) Quick-start checklist

- Document current batching recipes, device mappings and tolerances for a pilot line.

- Register all batching scales and feeders as assets with calibration and verification plans.

- Implement Batching Scale Software for one representative product family; validate.

- Integrate with WMS/ERP for lot identity and consumption; retire manual tally sheets.

- Run a mock recall and mass-balance check using only system data; adjust gaps and then roll out more broadly.

17) Extended FAQ

Q1. How is Batching Scale Software different from a standard PLC recipe?

A standard PLC recipe may know setpoints, but typically does not enforce per-ingredient tolerances, track lot IDs, manage calibration status or provide audit trails and batch-level genealogy. Batching Scale Software adds that governance and record-keeping on top of the control logic.

Q2. Can Batching Scale Software coexist with existing PLC control?

Yes. Many architectures keep fast, low-level control in PLCs but move recipe management, tolerances, lot mapping and record-keeping into Batching Scale Software that supervises the PLC.

Q3. Does Batching Scale Software replace our MES?

No. It is usually a module within or tightly integrated to MES. MES orchestrates overall production; Batching Scale Software focuses on automated ingredient dosing and its records.

Q4. Is Batching Scale Software relevant outside food?

Absolutely. It is equally relevant in dietary supplements, pharma, cosmetics, agricultural chemicals, resins and any process industry where multiple components are automatically dosed into a batch.

Q5. How do we validate Batching Scale Software?

Under your VMP, combine software CSV with equipment IQ/OQ/PQ and integrated performance qualification, including challenge tests for tolerances and alarms.

Q6. What is the minimum viable Batching Scale Software deployment?

Controlled recipes and tolerances, device and lot mapping, capture of delivered mass per ingredient, basic audit trails, and integration to your batch record—even if some advanced features (allergen zoning, rework limits) come later.

Q7. How does Batching Scale Software affect operators?

Operators see guided screens instead of manual charts; they intervene less in control and more in exception handling. Training focuses on responding to alarms and following controlled workflows, not on hand-tuned batching.

Q8. Can Batching Scale Software improve yield as well as compliance?

Yes. Once you can see overshoot patterns, rework contributions and mass-balance gaps per ingredient and per feeder, it becomes much easier to tune equipment, ingredient strategy and maintenance to reduce loss.

Related Reading

• Foundations: Batch Weighing | Gain-in-Weight vs Loss-in-Weight Feeding | Load Cells & Weighing Systems

• Traceability & Quality: Lot Traceability | Mass Balance | Audit Trail

• Systems: MES | WMS | LIMS

• V5 Products: V5 Solution Overview | V5 MES | V5 WMS | V5 QMS | V5 Connect API

OUR SOLUTIONS

Three Systems. One Seamless Experience.

Explore how V5 MES, QMS, and WMS work together to digitize production, automate compliance, and track inventory — all without the paperwork.

Manufacturing Execution System (MES)

Control every batch, every step.

Direct every batch, blend, and product with live workflows, spec enforcement, deviation tracking, and batch review—no clipboards needed.

- Faster batch cycles

- Error-proof production

- Full electronic traceability

Quality Management System (QMS)

Enforce quality, not paperwork.

Capture every SOP, check, and audit with real-time compliance, deviation control, CAPA workflows, and digital signatures—no binders needed.

- 100% paperless compliance

- Instant deviation alerts

- Audit-ready, always

Warehouse Management System (WMS)

Inventory you can trust.

Track every bag, batch, and pallet with live inventory, allergen segregation, expiry control, and automated labeling—no spreadsheets.

- Full lot and expiry traceability

- FEFO/FIFO enforced

- Real-time stock accuracy

You're in great company

How can we help you today?

We’re ready when you are.

Choose your path below — whether you're looking for a free trial, a live demo, or a customized setup, our team will guide you through every step.

Let’s get started — fill out the quick form below.