Electronic Batch Record Software — From Paper BMR to Enforced eBMR

This topic is part of the SG Systems Global regulatory & operations glossary.

Updated November 2025 • Electronic Batch Record Software, eBMR, MES, data integrity, Part 11, Annex 11, review by exception • Pharmaceutical, Biologics, ATMPs, Medical Devices, Dietary Supplements, Food & Beverage, Cosmetics, Agricultural Chemicals

Electronic Batch Record Software turns the batch record from a static, handwritten report into a live execution system. Instead of writing down what (you hope) happened, operators follow on-screen instructions, scanners and instruments feed attributable data, and the software enforces recipe, limit and sequencing rules. The result is a compliant Electronic Batch Record (eBMR) that is created as a by-product of doing the job correctly.

Where a traditional Batch Manufacturing Record (BMR) or Pharmaceutical Batch Record proves that a batch met GMP, Electronic Batch Record Software goes further: it makes it hard to do the wrong thing and easy to review the right things, while satisfying 21 CFR Part 11, Annex 11, GAMP 5 and modern data integrity expectations.

“Electronic Batch Record Software is not just ‘the batch record on a screen’. It is the engine that makes the correct process the only process, and leaves a clean trail when reality disagrees.”

It gives QA, regulators and sponsors a defensible record across pharma, biologics, medical devices, dietary supplements, food, cosmetics and other regulated process industries.

1) What Electronic Batch Record Software actually does

Electronic Batch Record Software is typically delivered as part of, or tightly integrated with, a Manufacturing Execution System (MES). In practical terms it:

- Stores and versions the Master Batch Record (MBR)/MMR, including recipes, steps, limits and instructions.

- Turns the MBR into executable workflows for operators and supervisors, bound to specific lines, equipment and roles.

- Connects to scales, PLCs, PAT tools and lab systems so data flows directly into the eBMR without transcription.

- Applies interlocks and checks so that wrong materials, wrong lots, out-of-status equipment, wrong parameters or missing tests simply block progression.

- Generates a complete, reviewable eBMR with audit trails, signatures, attachments and links to deviations, CAPA and lab results.

2) Key capabilities of Electronic Batch Record Software

| Capability | What it means in practice | Glossary anchors |

|---|---|---|

| MBR/MMR Management | Authoring, version control, approval and deployment of master batch recipes across sites | MBR, MMR, Change Control |

| Guided Execution | Step-by-step electronic instructions, checks and data-entry screens, driven by the MBR | Work Order Execution, Recipe & Parameter Enforcement |

| Material Control | Barcode-based material and lot selection, weigh & dispense, reconciliation | Weigh & Dispense Automation, Material Identity Confirmation |

| Equipment & Line Clearance | Equipment status, cleaning and line-clearance checks integrated into execution | Line Clearance, IQ/OQ/PQ |

| Process Data & CPPs | Collection and evaluation of process data (CPPs, IPCs, PAT), alarms and holds | CPPs, IPV |

| Deviation & CAPA Hooks | Automatic deviation triggers on out-of-limit events, with links to CAPA | Deviation/NC, CAPA |

| Review by Exception | Highlighting of exceptions for QA, instead of line-by-line manual review | Batch Review by Exception (BRbE) |

| Data Integrity & Signatures | Audit trails, e-signatures, retention & access control mapped to Part 11/Annex 11 | Part 11, Annex 11, Data Integrity |

| Integration & Traceability | Links to LIMS, WMS, ERP and serialisation for full lot/serial genealogy | End-to-End Lot Genealogy, LIMS |

3) Where Electronic Batch Record Software is used

Electronic Batch Record Software is now common in:

- Pharmaceutical manufacturing. Solid oral, sterile injectables, biologics, ATMPs and APIs under 21 CFR 210/211 and EU GMP.

- Medical device & combination products. In-process steps and Device History Records (DHR) for sterile devices, drug–device combinations and diagnostics.

- Dietary supplements. 21 CFR 111-driven manufacturing and packaging, tying eBMR to Supplement Facts and potency.

- Food & high-care processes. High-risk products (e.g. infant formula, nutraceutical beverages, aseptic foods) where batch execution needs electronic proof.

- Cosmetics & personal care. Manufacturers that want MoCRA and ISO 22716 compliance with clear links to formulations, CPSR/PIF and micro control.

- Agricultural chemicals, resins and coatings. Plants seeking tighter batch control for regulatory, safety or performance reasons.

4) Moving from paper BMRs to Electronic Batch Record Software

A typical evolution looks like this:

- Stage 1 — controlled paper. Pre-printed, pre-approved BMRs; basic logbooks; heavy QA effort to catch errors.

- Stage 2 — hybrid records. Some data captured electronically (e.g. weigh & dispense, HMI printouts), then attached physically or via document management; integration is weak.

- Stage 3 — full eBMR. MBR lives inside Electronic Batch Record Software; operators execute steps on terminals; instruments and LIMS feed data directly; QA moves to review by exception.

The biggest wins usually appear as soon as weighing/dispensing, material identity and CPP capture move from handwritten entries to enforced, scanned and validated entries in the eBMR.

5) Data integrity, Part 11 and Annex 11 in eBMR

Electronic Batch Record Software sits squarely in the scope of Part 11 and Annex 11 because it controls and stores primary GMP data:

- Unique users & roles. No shared accounts; authorised roles control who can execute steps, override limits or approve changes.

- E-signatures. Signatures have meaning (e.g. “performed”, “checked”, “approved”) and are bound to identity, time and the signed content.

- Audit trails everywhere. Changes to instructions, limits, results and signatures are all captured via GxP audit trails.

- Validated systems. Electronic Batch Record Software is subject to CSV under GAMP 5; configuration and customisation follow formal change control.

- Retention & archival. eBMRs are retained in readable form for years, with robust backup and restore processes.

6) Batch Review by Exception (BRbE) and QA efficiency

One of the strongest arguments for Electronic Batch Record Software is the ability to shift QA from document chasing to risk-based review:

- Rules-driven exceptions. The system flags steps where limits were approached or exceeded, data were missing, corrections were made, or manual overrides occurred.

- Focused QA effort. QA spends time on exceptions and trends instead of re-checking every normal entry.

- Faster release. Batches that execute cleanly can be reviewed and released quickly, shrinking inventory and lead times.

- Better trending. Exceptions across batches feed into APR/PQR and CPV in a structured way.

7) Integration: eBMR, LIMS, WMS, ERP and traceability

Electronic Batch Record Software becomes dramatically more valuable when it integrates with surrounding systems:

- LIMS. Sampling plans, tests and results (OOS/OOT, trending) flow into the eBMR automatically, eliminating manual transcription and spotting missing tests.

- WMS. Batch-to-bin and shipping data close the loop between execution and distribution, enabling rapid recall analysis.

- ERP. Orders, batch sizes and inventory movements are reconciled with what actually happened in execution.

- Serialisation/UDI. For pharma and devices, serials and UDI hierarchies are linked to the underlying eBMR and lot genealogy.

8) How V5 by SG Systems Global delivers Electronic Batch Record Software

V5 Traceability includes Electronic Batch Record capabilities as part of its MES platform for regulated process industries:

- MBR-driven execution. In V5 MES, master recipes (MBR/MMR) are implemented as stepwise workflows with enforced limits, device bindings and acceptance logic.

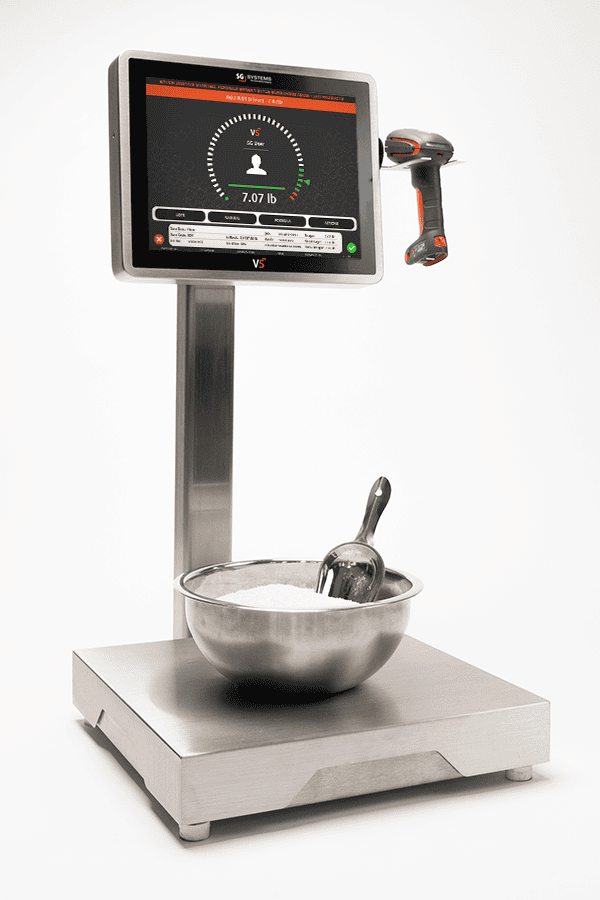

- Weigh & dispense enforcement. V5 combines weigh & dispense automation with barcode validation and tolerance checks, feeding directly into the eBMR.

- Device integration. Scales, HMIs, PLCs, checkweighers and PAT tools are integrated so that process data enters the record as attributable signals, not as copied values.

- Exception-based QA. V5 supports configured rules for Batch Review by Exception, highlighting the steps QA actually needs to look at.

- Traceability & WMS. Combined with V5 WMS and the V5 Connect API, the eBMR becomes a node in a full lot genealogy from intake to shipment.

9) KPIs for Electronic Batch Record Software

- Right-first-time batch records: % of eBMRs that pass QA review without correction.

- Review cycle time: average time from production complete to QA release decision per batch.

- Manual corrections per batch: count and trend of manual data edits or overrides.

- Transcription incidents: number of errors traced to manual copying from instruments or paper.

- Deviation-to-batch linkage: % of deviations correctly linked to affected eBMRs and lots.

10) Common pitfalls when deploying Electronic Batch Record Software

- “Glass BMR” syndrome. Simply copying paper forms into screens without rethinking workflows, interlocks and usability.

- Over-complicated MBR design. MBRs with excessive branching and free text, making configuration, validation and training harder than necessary.

- Partial device integration. Leaving key instruments “offline” so operators still transcribe critical data.

- Ignoring change management. Underestimating the culture shift from “write what you did” to “do what the system enforces”.

- Weak integration with LIMS and WMS. Forcing QA to open multiple systems and reconcile data manually, defeating much of the benefit.

11) FAQ — Electronic Batch Record Software

Q1. What is Electronic Batch Record Software?

Electronic Batch Record Software is a system, usually part of an MES, that replaces paper batch records with electronic, Part 11/Annex 11-compliant execution and documentation. It guides operators through the process, captures data from devices and users, and generates the complete eBMR for each batch.

Q2. Is Electronic Batch Record Software only for pharmaceuticals?

No. While pharma and biologics are early adopters, eBMR is increasingly used in medical devices (via DHR-like records), dietary supplements, high-risk foods, cosmetics and other process industries that operate under strict quality systems.

Q3. How is Electronic Batch Record Software different from a document management system?

Document management systems store and route documents. Electronic Batch Record Software executes processes: it orchestrates steps, prompts users, enforces limits and automatically collects data and signatures while generating the record.

Q4. Do we need to replace our ERP to use eBMR?

Usually not. ERP remains the system of record for finance, planning and high-level inventory, while eBMR software runs execution on the shop floor and integrates with ERP via APIs or interfaces.

Q5. How long does data from Electronic Batch Record Software need to be retained?

Retention depends on regulation and product type (e.g. years past expiry for pharmaceuticals). eBMR systems must support long-term record retention and archival, including format migrations and validated restore processes.

Q6. Can Electronic Batch Record Software support multi-site deployment?

Yes. Many organisations use a central MBR library and configuration model with local site adaptations, allowing consistent processes and templates across plants while respecting local equipment and regulatory nuances.

Q7. What is the minimum viable eBMR implementation?

A pragmatic starting point is: controlled MBRs, electronic execution for weighing/dispensing and key process steps, basic device integration, structured deviation capture and QA review using the eBMR as the source of truth, even if some areas (e.g. packaging) remain partly manual initially.

Q8. How should we evaluate Electronic Batch Record Software?

Look at: usability for operators; flexibility and governance of MBR templates; depth of device and LIMS/WMS integration; strength of data-integrity controls; ability to support review by exception; and vendor track record in your regulatory domain.

Related Reading

• Records & Recipes: Batch Manufacturing Record (BMR) | Electronic Batch Record (eBMR) | Master Batch Record (MBR) | Master Manufacturing Record (MMR)

• Execution & Control: MES | Recipe & Parameter Enforcement | Weigh & Dispense Automation | Batch Review by Exception

• Compliance & Integrity: 21 CFR Part 11 | Annex 11 | GAMP 5 | Data Integrity

OUR SOLUTIONS

Three Systems. One Seamless Experience.

Explore how V5 MES, QMS, and WMS work together to digitize production, automate compliance, and track inventory — all without the paperwork.

Manufacturing Execution System (MES)

Control every batch, every step.

Direct every batch, blend, and product with live workflows, spec enforcement, deviation tracking, and batch review—no clipboards needed.

- Faster batch cycles

- Error-proof production

- Full electronic traceability

Quality Management System (QMS)

Enforce quality, not paperwork.

Capture every SOP, check, and audit with real-time compliance, deviation control, CAPA workflows, and digital signatures—no binders needed.

- 100% paperless compliance

- Instant deviation alerts

- Audit-ready, always

Warehouse Management System (WMS)

Inventory you can trust.

Track every bag, batch, and pallet with live inventory, allergen segregation, expiry control, and automated labeling—no spreadsheets.

- Full lot and expiry traceability

- FEFO/FIFO enforced

- Real-time stock accuracy

You're in great company

How can we help you today?

We’re ready when you are.

Choose your path below — whether you're looking for a free trial, a live demo, or a customized setup, our team will guide you through every step.

Let’s get started — fill out the quick form below.