Food Traceability Program — From Farm Intake to Retail Shelf in One Connected Chain

This topic is part of the SG Systems Global regulatory & operations glossary.

Updated November 2025 • Food Traceability Program, FSMA 204 KDE/CTE, PTI, one-up/one-down, mock recalls, batch-to-bin traceability • Food Processing, Sausage & Meat, Bakery, Produce Packing, Ingredients & Dry Mixes, Consumer Packaged Foods

A Food Traceability Program is the structured combination of people, processes and systems that delivers reliable end-to-end lot genealogy across the food supply chain. It connects farm or live-animal intake, ingredient receiving, batching and processing, thermal steps, packaging, cold storage, distribution and retail or food-service customers into one coherent story. It must satisfy legal expectations such as 21 CFR 117 and FSMA 204 Key Data Elements (KDE), as well as schemes like BRCGS traceability requirements, SQF mass balance, retailer programs and export expectations.

Done well, a Food Traceability Program turns “we think that lot went to those customers” into a precise, data-backed answer: which ingredients, which lines, which batches, which cases, which pallets, which customers and how much risk.

“A Food Traceability Program is what lets you move from ‘we’re recalling everything’ to ‘we’re recalling exactly this.’”

1) Why you need a Food Traceability Program now — hard truths

- Regulators are specifying the “how”, not just the “what”. FSMA 204 Traceability Rule did not just say “keep records”; it defined Key Data Elements at Critical Tracking Events. BRCGS and SQF expect mock recalls with mass balance, not binder hunts.

- Retailers and brand owners run their own risk models. They expect suppliers to provide case-level and sometimes unit-level traceability, plus support for programs like Walmart SQEP and PTI. Weak traceability means lost business.

- Multi-site and co-manufacturing are normal. Ingredients and work-in-progress now move between plants, 3PL cold stores and contract manufacturers. A Food Traceability Program has to survive those hand-offs.

- Product portfolios are exploding. Line extensions, private label, limited editions and multi-pack formats all increase traceability complexity; spreadsheets don’t scale.

- Recalls are expensive even when you “win”. Over-scoping because you can’t define exact exposure destroys margin and brand trust, even when there is no illness or injury.

2) Scope of a Food Traceability Program

| Element | What it covers | Glossary anchors |

|---|---|---|

| Identification & Coding | Lot/batch IDs, case & pallet labels, PTI/GS1-128 formats, clip/date codes | GS1-128 Case Label, SSCC, PTI |

| Lot Genealogy | Links from raw intake through batching and processing to finished goods | End-to-End Lot Genealogy, Batch Genealogy |

| Critical Tracking Events (CTE) | Intake, transformation, packing, cooling, storage, shipping | FSMA 204 KDE/CTE |

| Warehouse & Cold Chain | Batch-to-bin mapping, FEFO, temperature mapping, route building | Batch-to-Bin Traceability, Temperature Mapping |

| Quality & Food Safety | HACCP, CCP/PC records, micro & chemistry, hold/release, rework | HACCP, Hold/Release, Rework Traceability |

| Mock Recalls & Mass Balance | Recall drills, trace-back, trace-forward, yield and mass-balance checks | Mock Recall Performance, Mass Balance |

| Data Integrity & Records | User access, audit trails, retention, controlled change | Data Integrity, Record Retention & Archival |

| Systems & Integrations | ERP, MES, WMS, LIMS, label systems, 3PL and trading partner links | MES, WMS |

3) Food Traceability Program by industry

SG Systems works across multiple food sectors. The basics of a Food Traceability Program are shared, but each industry has its own emphasis.

3.1 Sausage & meat processing manufacturing

In sausage & meat processing manufacturing, traceability must cope with variable-weight and complex processing:

- GS1-128 intake & combos. GS1-128 raw material intake labeling for primals and trim; combos tracked from intake through grind and mix.

- Catch-weight traceability. Catch-weight traceability extends from combo weight to chub/tray weight and case/pallet totals.

- Thermal and lethality records. Mixer-to-smokehouse load validation, FSIS Appendix A and Appendix B compliance are part of the genealogy, not separate spreadsheets.

- Foreign-material linkage. Metal detector verification tests and X-ray bone fragment detection validation link to lots and loads.

3.2 Bakery manufacturing

In bakery manufacturing, a Food Traceability Program focuses on ingredients, sponge & dough and allergen zoning:

- Flour & ingredient intake. Flour Scaling & Silo Weighing tracks mill lots and silo dedications; minor & micro ingredient stations record small-component pulls.

- Sponge and preferments. Sponge and Dough System and preferment scaling provide genealogy through fermentation.

- Allergen changeovers. Allergen Changeover Verification and Allergen Segregation Control tie cleaning and verification to line and product sequence.

- Clip codes & routes. Bag codes and route/trolley movements link finished product back to dough batches and forward to stores.

3.3 Food processing & ingredients/dry mixes

In food processing and ingredients & dry mixes manufacturing, traceability is about complex batching across multiple products:

- Weigh & dispense. Weigh and dispense automation and paperless dispensing ensure that every ingredient pull is linked to both the lot and the batch record.

- Cross-batch lot allocation. Cross-batch lot allocation logic manages how big lots are spread across many batches and products.

- Dry mix as component. Dry blends may themselves become traceable ingredients for other sites, requiring end-to-end traceability across companies.

3.4 Produce packing

In produce packing, a Food Traceability Program aligns strongly with PTI and FSMA 204:

- Field and harvest data. Field, block, GPS, grower and harvest-crew data are encoded as PTI key data elements.

- Cooling and pack events. Cooling, initial pack and shipping appear as FSMA 204 critical tracking events, each with their own KDE.

- Case and pallet labels. Case IDs and SSCC pallets make the whole chain scannable from field trailer to retailer DC.

3.5 Consumer packaged food products

In consumer products manufacturing that include food (snacks, drink mixes, ready meals), a Food Traceability Program has to manage co-manufacturers, multi-site filling and marketing-led changes. Many of the same patterns above apply, but the emphasis is on co-man traceability and artwork/version control.

4) FSMA 204 KDE/CTE and Critical Tracking Events

FSMA’s Traceability Rule (FSMA 204) formalises what many food companies already suspected: it is not enough to have traceability somewhere; you must reliably capture specific data at specific Critical Tracking Events:

- Growing and harvesting. Where food is grown or animals are raised, who harvested it, and when.

- Cooling and initial packing. When perishable products are first cooled and packed; how they move from farm to pack house.

- Transformation. When ingredients are combined, ground, mixed, cooked, sliced or otherwise transformed into new products.

- Shipping and receiving. When foods move between entities, which lots and quantities were involved, and what IDs were used.

A Food Traceability Program expresses these FSMA 204 CTEs as events in MES, WMS and ERP, with each event capturing Key Data Elements like lot, location, date/time, quantity and sender/receiver.

5) Batch-to-bin traceability and the role of warehouses

Warehouses and cold stores are often the weakest link in a Food Traceability Program. Batch-to-bin traceability closes that gap:

- Location mapping. Every rack, bay, room, freezer or cooler location has an ID; pallets and lots are scanned into and out of those locations.

- FEFO and rotation. FEFO logic, not habit, determines pick sequences; this ties directly into shelf-life and complaint data.

- 3PL integration. Third-party cold stores and DCs either use your IDs or provide scan data that can be reconciled to your lot and pallet IDs.

- Returns and rework. Returned goods and rework are treated as traceable lots with full history, not anonymous “misc” inventory.

Without batch-to-bin traceability, even the best plant-level program breaks when product is moved, consolidated or cross-docked.

6) Data integrity, systems and the Food Traceability Program

A Food Traceability Program only works if you trust the underlying data:

- Unique users & access control. No shared logins on scanners, batching stations or WMS terminals; roles are managed under User Access Management.

- Audit trails. Key actions—lot changes, overrides, label reprints, recall scope adjustments—are logged via Audit Trail (GxP) logic.

- Time synchronisation. MES, WMS, LIMS and ERP share a timebase so event order makes sense across systems.

- Retention & retrieval. Traceability records are kept readable and accessible for as long as your regulators, customers and internal policies require.

7) Implementation playbook — building a Food Traceability Program that works

- Map traceability goals by customer and regulator. Start with HACCP, FSMA 204, BRCGS/SQF and top-customer requirements; turn them into a concrete list of “must be able to answer” questions.

- Standardise IDs and labels. Choose and lock in lot ID formats, case and pallet labels (GS1-128, PTI, internal codes) across plants and 3PLs.

- Instrument your Critical Tracking Events. For each product family, define intake, transformation, packing and shipping events; enforce scan-based data capture there first.

- Connect MES, WMS and ERP. Use integrations so that batch numbers, case IDs and customer orders match across systems without manual mapping.

- Run mock recalls and mass-balance checks. Measure how long it takes to trace forward/back from a test lot; refine processes until the result is reliable and fast.

8) How V5 Traceability supports a Food Traceability Program

V5 Traceability from SG Systems Global provides an execution and warehouse backbone that many Food Traceability Programs use as their data source:

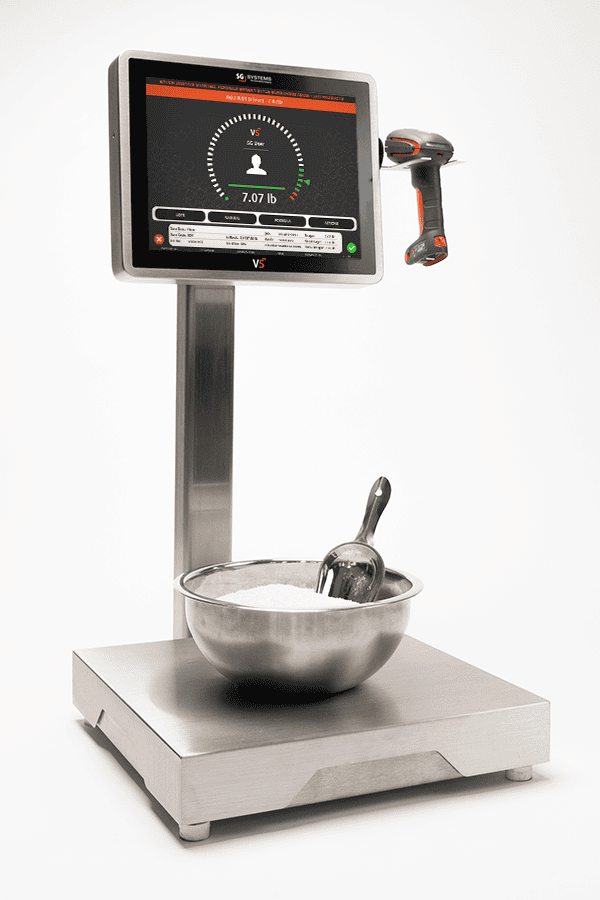

- Execution control. V5 MES manages weigh-and-dispense, recipe enforcement, grind and mix, sponge and dough, thermal processing and packaging for food, meat, bakery, supplements and ingredients.

- Warehouse & logistics. V5 WMS handles bin/location management, batch-to-bin traceability, FEFO, route building and integration with 3PLs.

- Quality & food safety. V5 QMS ties deviations, complaints, CAPA, micro and stability studies directly to lots and batches, supporting recall and root-cause analysis.

- Integration platform. The V5 Connect API links V5 to ERP, LIMS, label engines and external portals, making traceability data available across the supply chain.

9) KPIs that show your Food Traceability Program is working

- Genealogy completeness: % of shipped volume with complete upstream/downstream lot history (target 100%).

- Mock recall time: minutes from trigger (supplier lot, process deviation, complaint) to final list of affected products and customers.

- Mass-balance closure: % of recall or mock-recall scenarios where input vs. output reconciles within agreed tolerances.

- 3PL & co-man alignment: % of external partners using your IDs/labels or providing data that reconciles cleanly.

- Traceability-related audit findings: number and severity of non-conformances in third-party or regulatory audits per year.

- Untraceable lots or cases: count of items where full trace-back/trace-forward cannot be produced within SLA (target: zero).

10) Common pitfalls in Food Traceability Programs

- Lot IDs that change at every step. Internal re-lotting without clear linkages makes genealogy unnecessarily complex.

- Traceability only inside one plant. Once product hits a 3PL, depot or co-man, visibility is lost.

- Heavy reliance on spreadsheets. “Master trace” workbooks, often maintained by one person, are fragile and rarely auditable.

- Untracked rework and returns. Rework streams and RMAs treated as generic stock rather than traceable lots.

- Mock recalls treated as paperwork, not practice. Drills done on paper with idealised data instead of using real systems and operators.

11) FAQ — Food Traceability Program

Q1. What is a Food Traceability Program?

A Food Traceability Program is the documented set of policies, procedures, systems and metrics that define how a food business achieves lot-level traceability from raw materials to customers and back again, including responsibilities, data standards and recall practices.

Q2. Is a Food Traceability Program the same as traceability software?

No. Software (MES, WMS, ERP, label and scanning systems) provides the tools and data for traceability. The Food Traceability Program defines how those tools are used, who owns them and how performance is measured.

Q3. How does a Food Traceability Program relate to HACCP?

HACCP identifies hazards and control measures; a Food Traceability Program ensures you can trace affected product when a hazard, CCP deviation or complaint occurs, and demonstrate control during audits and investigations.

Q4. What’s the link between a Food Traceability Program and FSMA 204?

FSMA 204 specifies certain foods and critical tracking events where additional KDE must be captured. A Food Traceability Program incorporates those requirements into everyday operations so FSMA 204 requests can be answered quickly and accurately.

Q5. Do small and mid-sized processors really need a formal program?

Yes. The scale can be lighter, but customers and regulators increasingly expect written traceability procedures, clear responsibilities and evidence that recalls can be executed quickly.

Q6. How often should we run mock recalls?

Typically at least once per year per major product family or site, with additional drills when new systems, partners or high-risk processes are added.

Q7. Can a Food Traceability Program be shared across multiple plants?

Yes—and that is often the goal. Corporate programs define standards for lot IDs, labels, data capture and KPIs, while each site implements the specifics on its lines and local systems.

Q8. What is the first step if our current traceability is weak?

Start by mapping your current trace data: what you can and cannot answer today. Then stabilise IDs, instrument a few key tracking events, and run honest mock recalls to prioritise gaps. Technology should support that strategy, not drive it blindly.

Related Reading

• Foundations: Traceability (End-to-End Lot Genealogy) | Batch Genealogy | One-Up / One-Down Traceability

• Regulations & Programs: 21 CFR 117 | FSMA 204 Traceability Rule | BRCGS Traceability Requirements | SQF Mass Balance

• Execution & Tools: Weigh & Dispense Automation | Batch-to-Bin Traceability | Mock Recall Performance

OUR SOLUTIONS

Three Systems. One Seamless Experience.

Explore how V5 MES, QMS, and WMS work together to digitize production, automate compliance, and track inventory — all without the paperwork.

Manufacturing Execution System (MES)

Control every batch, every step.

Direct every batch, blend, and product with live workflows, spec enforcement, deviation tracking, and batch review—no clipboards needed.

- Faster batch cycles

- Error-proof production

- Full electronic traceability

Quality Management System (QMS)

Enforce quality, not paperwork.

Capture every SOP, check, and audit with real-time compliance, deviation control, CAPA workflows, and digital signatures—no binders needed.

- 100% paperless compliance

- Instant deviation alerts

- Audit-ready, always

Warehouse Management System (WMS)

Inventory you can trust.

Track every bag, batch, and pallet with live inventory, allergen segregation, expiry control, and automated labeling—no spreadsheets.

- Full lot and expiry traceability

- FEFO/FIFO enforced

- Real-time stock accuracy

You're in great company

How can we help you today?

We’re ready when you are.

Choose your path below — whether you're looking for a free trial, a live demo, or a customized setup, our team will guide you through every step.

Let’s get started — fill out the quick form below.