Manufacturing Traceability Software — Lot Genealogy for Process Industries

This topic is part of the SG Systems Global regulatory & operations glossary.

Updated November 2025 • Manufacturing Traceability Software, process manufacturing, end-to-end lot genealogy, batch tracking, FSMA 204, DSCSA, UDI, GFSI, MoCRA • Pharmaceutical, Medical Device, Food & Beverage, Sausage & Meat, Bakery, Dietary Supplements, Cosmetics, Agricultural Chemicals, Plastic & Resin, Ingredients & Dry Mixes, Consumer Products

Manufacturing traceability software is the system that sits underneath modern process plants and answers the hardest questions in an investigation or recall: which raw materials went into this batch, what happened to them, and which customers or patients could be affected? It connects intake, batching, reactors and mixers, tanks and transfer lines, thermal steps, packaging, warehouses and returns into one digital end-to-end lot genealogy.

Unlike traceability tools aimed at discrete assembly, manufacturing traceability software for processing industries has to deal with blending, splitting, rework, variable potency and continuous or semi-continuous flows. It is the backbone for sectors such as pharmaceutical manufacturing, dietary supplements, food processing, sausage & meat processing, bakery manufacturing, cosmetics manufacturing, agricultural chemical manufacturing, plastic & resin manufacturing, ingredients & dry mixes and complex consumer products manufacturing.

“Manufacturing traceability software is the difference between knowing exactly which batches and customers are in scope, and recalling everything because you can’t prove what happened.”

1) Why manufacturing traceability software matters for process industries

- Batches and flows mix everything together. Reactors, mixers, grinders, silos and tanks naturally blend lots; without software, it is very hard to see which inputs affected which outputs.

- Regulatory demands keep increasing. DSCSA and drug serialisation, UDI, FSMA 204, BRCGS meat controls, ISO 22716, MoCRA and national agrochemical or resin standards all assume you can reconstruct history quickly.

- Contract manufacturing and tolling introduce more hand-offs. Many brands now rely on CMOs, tollers and 3PLs. Manufacturing traceability software provides the common language across organisations.

- Quality and yield improvements depend on genealogy. You cannot optimise yield, solve recurring deviations or reliably compare suppliers without knowing which lots went where and how they behaved.

- Recalls without precision are financially brutal. Over-scoping recalls because genealogy is weak destroys margin and brand trust, especially for high-value actives or specialty resins.

2) Scope of manufacturing traceability software for process industries

| Area | What the software controls | Glossary anchors |

|---|---|---|

| Raw Material Intake | Suppliers, COA, lot IDs, sampling, quarantine & release | Component Lot Traceability, Hold/Release |

| Weigh & Dispense | Automatic and manual dosing, scales, pre-weigh & kitting | Weigh & Dispense Automation, Material Staging & Kitting |

| Batch & Reactor Control | Mixers, reactors, tanks, transfers, rework and CIP/SIP | ISA-88 Batch Control, Batch Reactor Vessel Control |

| Process Parameters & IPC | CPPs, IPC limits, alarms, deviations and approvals | CPPs, IPV, Deviation/NC |

| Packaging & Labelling | Container IDs, serialisation, case & pallet labels, artwork versions | Serialization, GS1-128 Case Label, Labeling Control |

| Warehouse & Logistics | Batch-to-bin mapping, FEFO, routes, 3PL integration, returns | Batch-to-Bin Traceability, Returns/RMA |

| Quality & Testing | Sampling plans, lab tests, stability, micro, release, trend analysis | LIMS, Stability Studies |

| Compliance & Records | Electronic batch records, DHR, PIF/CPSR links, data integrity | eBMR, DHR, PIF, Data Integrity |

3) From raw intake to weigh & dispense — where genealogy begins

Manufacturing traceability software starts working the moment material crosses the dock.

- Component lot traceability. Each delivery is captured with supplier, COA, inspection results and a stable internal lot ID using Component Lot Traceability principles.

- Sampling and quarantine. Sampling plans and status (quarantine, released, rejected) are controlled under Hold/Release logic.

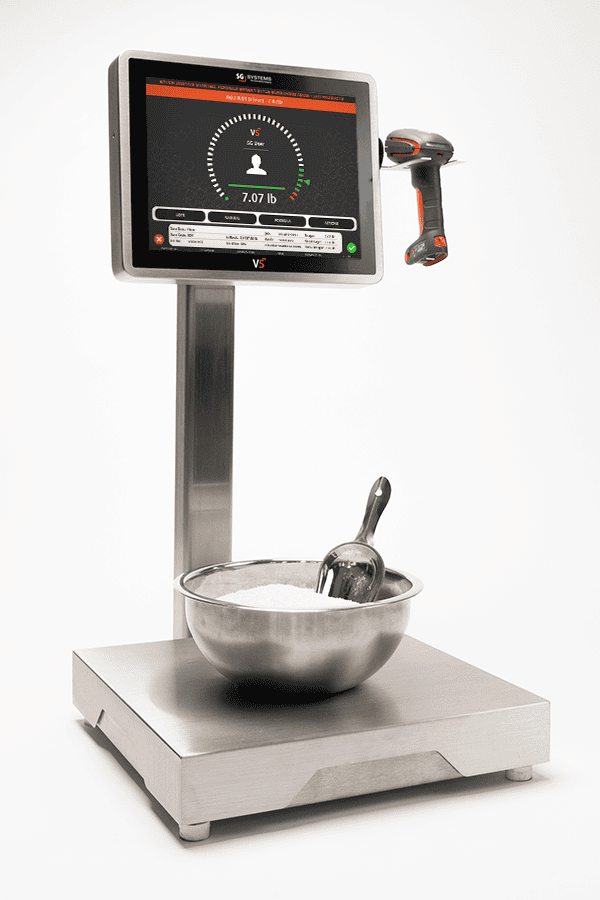

- Weigh & dispense automation. Weigh & Dispense Automation and paperless dispensing enforce barcode scanning, correct items and lots, and capture actual weights, taring and operator IDs.

- Pre-weigh and kitting. For dry mixes, bakery, supplements and cosmetics, material staging & kitting logic links pre-weighed kits to downstream batches.

This ensures that the first link in genealogy—which lots were available for which batches—is built into day-to-day work rather than calculated later.

4) Batching, reactors and process parameters — capturing what actually happened

In processing industries, batches can be large, long-running and complex. Manufacturing traceability software uses standards like ISA-88 to keep them under control:

- Batch recipe execution. Batch Recipe Execution (BRE) links each batch to a recipe version, including setpoints, steps and equipment modules.

- Tank and reactor genealogy. Batch reactor vessel control records which lots entered which tank or reactor, with times, transfers, top-ups and rework additions.

- CPPs and IPCs. Critical parameters such as temperature, pH, viscosity, agitation speed or cook time are logged and enforced under CPP and IPC logic. Deviations are captured as Non-conformances.

- Continuous and campaign modes. For resins, agricultural chemicals and some foods, continuous or campaign operations are handled with “virtual batches” and residence-time models that still allow traceability within acceptable windows.

All of these events become part of the genealogy, so that later you can answer not just “where did this batch go?” but “what conditions and deviations applied to it?”

5) Packaging, serialisation and labelling — how traceability leaves the plant

Manufacturing traceability software treats packaging and labelling as core genealogy events:

- Container and unit IDs. For pharma, devices and some cosmetics, container or device IDs (blister, vial, syringe, bottle, unit pack) carry serialisation and UDI data.

- Case and pallet labels. For food, ingredients and chemicals, GS1-128 case labels and SSCC pallets are generated by the software and tied back to batch and plant data.

- Label version control. Labeling control ensures each batch is associated with the correct artwork and text version, critical for dietary supplements, consumer products and cosmetics.

- Fill-finish verification. For cosmetics and OTC-like products, fill-finish line verification records line clearance, fill-volume checks and coding as part of the traceable event.

Once a unit, case or pallet leaves the plant, its identity is whatever is printed on the label. Manufacturing traceability software makes sure that identity can be decoded back into batches, lots and process history.

6) Warehouse, batch-to-bin and supply chain traceability

Process manufacturers increasingly rely on external warehouses and global distribution. Manufacturing traceability software extends genealogy beyond the production floor:

- Batch-to-bin mapping. Batch-to-Bin Traceability ties each pallet and lot to specific warehouse locations, including 3PLs.

- FEFO and inventory control. FEFO rotation, quarantine areas, rework locations and destruction processes are all recorded as traceable movements.

- Returns and RMAs. Returns & RMA logic ensures returned goods re-enter genealogy with full context, whether they are investigated, reworked or destroyed.

- Trading partner data. For DSCSA, UDI or PTI scenarios, shipment and receipt events shared with partners become part of the global genealogy graph.

7) Examples of manufacturing traceability software across process industries

- Pharmaceutical manufacturing. Links BMR/eBMR, API potency, excipient lots, environmental monitoring, sterility tests and DSCSA serials; supports APR/PQR and inspections.

- Medical device manufacturing. Connects DMR/DHR, component lots, sterilisation batches and UDI serials for targeted field actions.

- Dietary supplements manufacturing. Ties potency-adjustment factors, Supplement Facts labels, COAs, blend lots and tabletting/encapsulation lines to finished bottles and complaints.

- Cosmetics manufacturing. Links INCI ingredient lots, microbial control, preservative challenge tests, CPSR/PIF and packaging/batch codes.

- Agricultural chemicals. Combines Chemical Management System (CMS), reactor genealogy, packaging and GHS/SDS history for each lot.

- Plastic & resin manufacturing. Tracks monomer and additive lots, reactor conditions, pellet lots, colour batches and extruded products for performance claims and customer complaints.

- Ingredients & dry mixes. Provides multi-level genealogy where a single dry mix lot feeds multiple customer products and plants.

8) Mock recalls, investigations and analytics

The ultimate test of manufacturing traceability software is how it behaves when something goes wrong:

- Trace-back. From a suspect finished lot, complaint or field event, the system should show the full chain of raw-material, intermediate and process history.

- Trace-forward. From a suspect raw-material lot or deviation event, it should show all batches, units, customers and markets affected.

- Mock recall performance. Mock recall drills and mass-balance checks are used to validate that the software and processes work together.

- Continuous improvement. With genealogy in place, analytics on yield, scrap, rework, deviations and complaints by material, line or supplier become much more powerful.

9) How V5 works as manufacturing traceability software for process industries

V5 Traceability from SG Systems Global is designed as a manufacturing traceability system for process industries:

- Execution and batching. V5 MES manages weigh & dispense, ISA-88 batch execution, device integration and eBMR generation with enforced genealogy.

- Warehouse & logistics. V5 WMS provides batch-to-bin traceability, GS1-128/SSCC labels and integration with 3PLs.

- Quality and lab. V5 QMS and the V5 QMS – LIMS Integration tie deviations, CAPA, micro and stability directly to lots and batches.

- Integration layer. The V5 Connect API links ERP, formulation/PLM, CPSR/PIF tools, label engines and trading-partner systems, allowing genealogy to span your entire stack.

10) KPIs for manufacturing traceability software

- Genealogy completeness: % of released lots with full upstream/downstream genealogy (target 100%).

- Mock recall time: time from trigger to complete trace-back/trace-forward report for a chosen lot or material.

- Mass-balance closure: % of batches and recalls where inputs and outputs reconcile within defined tolerances.

- Label/serial accuracy: rate of label, coding or serialisation errors per million units.

- Data integrity incidents: count of audit findings involving missing, inconsistent or unverifiable traceability data.

11) Common pitfalls manufacturing traceability software should prevent

- Multiple lot IDs for the same material. Different systems re-lot or rename material without clear linkage.

- Traceability hidden in spreadsheets. Critical genealogy steps depend on offline Excel tools with no audit trail.

- Partial system coverage. Some plants or CMOs use the traceability system, others use local workarounds.

- Untracked rework and returns. Rework loops and RMAs are not modelled explicitly in the genealogy.

- Timebase drift. MES, LIMS and WMS clocks are not synchronised, making event ordering unreliable.

12) FAQ — Manufacturing Traceability Software

Q1. What is manufacturing traceability software?

Manufacturing traceability software is a system that captures and connects material movements, process events, test results and shipments into a coherent lot genealogy across the plant and supply chain, with a focus on batch and process industries.

Q2. How is manufacturing traceability software different from MES or ERP?

ERP manages orders and finance; MES runs the process steps. Manufacturing traceability software uses data from MES, WMS, LIMS and ERP to build and query a full genealogy. In many modern platforms, traceability is built into MES/WMS rather than a separate product, but the conceptual role is distinct.

Q3. Do I need manufacturing traceability software if I already have serialisation?

Serialisation (e.g. DSCSA, UDI) identifies units and cases, but by itself does not explain how they were made or which raw lots and process events they depend on. Manufacturing traceability software links serials to full batch and process history.

Q4. Can manufacturing traceability software work across multiple plants and partners?

Yes. Modern systems are designed for multi-site deployments and can exchange genealogy information with CMOs, tollers and 3PLs via APIs and standard identifiers.

Q5. What is the minimum viable manufacturing traceability system?

Stable lot IDs, scan-based intake and weigh & dispense, batch-level genealogy in MES, basic batch-to-bin mapping in warehouses, case/pallet labels tied to batches, and a practical way to run recalls and investigations within required timelines.

Q6. How long does genealogy data need to be kept?

Retention requirements depend on industry and regulation (e.g. years past expiry for pharma, market- and risk-based rules for foods and cosmetics). Manufacturing traceability software should support retention and archival policies under Record Retention & Archival.

Q7. Is manufacturing traceability software only for highly regulated industries?

No. Even in less-regulated sectors such as some consumer products or resins, genealogy is critical for customer complaints, warranty issues, performance claims and cost control.

Q8. How should we evaluate manufacturing traceability software?

Look at its ability to integrate with existing systems, handle complex batching and rework, support your regulatory context, generate fast trace-back/trace-forward reports, and survive multi-site and co-manufacturing scenarios.

Related Reading

• Foundations: Traceability (End-to-End Lot Genealogy) | Batch Genealogy | Mass Balance

• Execution & Control: Weigh & Dispense Automation | Batch Reactor Vessel Control | In-Process Controls

• Compliance & Systems: eBMR | UDI | DSCSA | FSMA 204 Traceability Rule

OUR SOLUTIONS

Three Systems. One Seamless Experience.

Explore how V5 MES, QMS, and WMS work together to digitize production, automate compliance, and track inventory — all without the paperwork.

Manufacturing Execution System (MES)

Control every batch, every step.

Direct every batch, blend, and product with live workflows, spec enforcement, deviation tracking, and batch review—no clipboards needed.

- Faster batch cycles

- Error-proof production

- Full electronic traceability

Quality Management System (QMS)

Enforce quality, not paperwork.

Capture every SOP, check, and audit with real-time compliance, deviation control, CAPA workflows, and digital signatures—no binders needed.

- 100% paperless compliance

- Instant deviation alerts

- Audit-ready, always

Warehouse Management System (WMS)

Inventory you can trust.

Track every bag, batch, and pallet with live inventory, allergen segregation, expiry control, and automated labeling—no spreadsheets.

- Full lot and expiry traceability

- FEFO/FIFO enforced

- Real-time stock accuracy

You're in great company

How can we help you today?

We’re ready when you are.

Choose your path below — whether you're looking for a free trial, a live demo, or a customized setup, our team will guide you through every step.

Let’s get started — fill out the quick form below.