Material Consumption Recording

This topic is part of the SG Systems Global manufacturing execution, inventory integrity and batch traceability glossary.

Updated December 2025 • material consumption recording, issue-to-order vs scan-to-consume, weighing & dispensing verification, component lot assignment, UoM conversions, inventory accuracy, batch yield reconciliation, batch review by exception, hard gating, audit trails, Part 11/Annex 11 data integrity • Pharmaceutical, Dietary Supplements, Food Processing, Ingredients & Dry Mixes, Cosmetics, Agricultural Chemicals, Plastic Resin, Consumer Products, Bakery, Sausage & Meat Processing, Produce Packing, Medical Devices

In regulated and high-consequence manufacturing, Material Consumption Recording is the difference between knowing what went into a batch and believing what went into a batch. The gap matters because modern audits, recalls, investigations, and margin analysis don’t accept “we think we used…”—they expect you to prove exactly which material lots were consumed, in what quantities, at which step, by which operator, and under what controls.

At SG Systems Global, we treat Material Consumption Recording as a core operational control: it connects your Bill of Materials (BOM) and Products & Formulas to real-world execution—where people pick, stage, weigh, dispense, charge, top-up, rework, scrap, and sometimes improvise. If your system doesn’t capture consumption at the moment it happens (or at least at a hard-controlled proxy event), you don’t have traceability; you have “after-the-fact accounting.”

It’s also where manufacturing and warehouse operations collide. You cannot record consumption reliably if the plant doesn’t control material identity and location. That’s why “consumption recording” is inseparable from Inventory Accuracy, FEFO discipline, and lot-level genealogy (Lot Traceability (End-to-End Genealogy)). If bins can move without scans and lots can be swapped without verification, your “consumption records” are decoration.

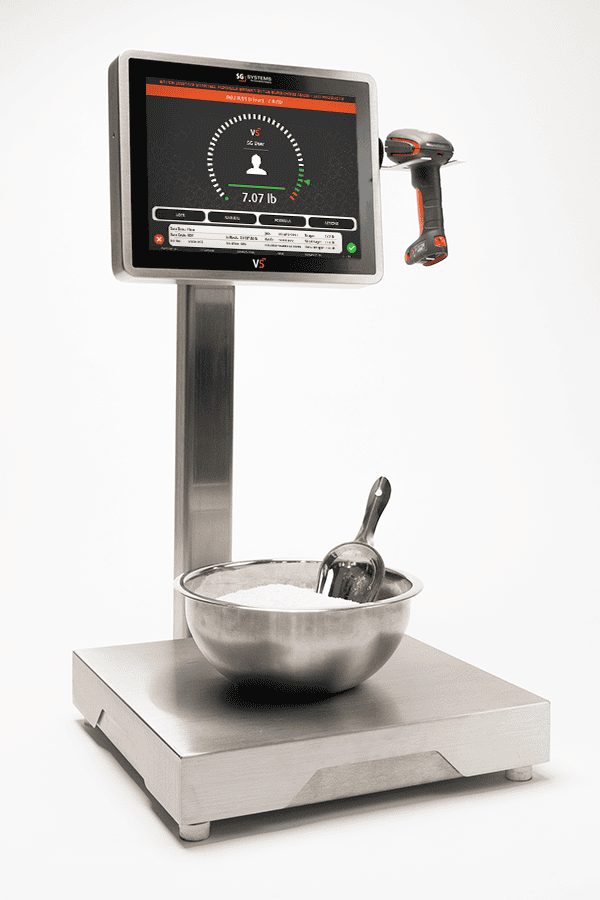

Figure: Ingredient batching systems only become audit-ready when consumption events (scan + weigh + step context) are recorded as controlled transactions—not as end-of-shift estimates.

When material consumption is recorded correctly, you get four outcomes that matter in the real world:

- Regulatory defensibility. Your batch record tells a coherent story aligned with GMP/cGMP expectations and electronic records requirements such as 21 CFR Part 11 and Annex 11, with complete Audit Trail evidence.

- Operational clarity. You can reconcile variances without a witch hunt, because each consumption event is tied to a step, a lot, and a person.

- Inventory truth. Your on-hand balances actually reflect what happened, not what someone typed after the fact.

- Margin control. You can see where yield is leaking, where over-issuing is normalised, and where rework is being used as a quiet patch.

“If you can’t prove what went into the batch—with lot IDs, weights, timestamps and approvals—you didn’t manufacture a product. You performed a controlled guess.”

1) Material consumption recording stack — what has to be connected

Material Consumption Recording is not one screen or one transaction. It’s a stack of controls that starts with master data and ends with review and reporting. The table below shows what must connect if you want consumption records that survive audits and help the plant run better.

| Layer | What it controls | Key glossary / system anchors |

|---|---|---|

| Master Data & BOM | Approved formulas, component lists, UoM rules, tolerances, substitutions |

BOM, Products & Formulas, Recipe & Parameter Enforcement |

| Identity & Lot Control | Confirming the right item and the right lot at the point of use |

Material Identity Confirmation, Material Lot Assignment, Component Identity Barcode Verification |

| Warehouse Truth | Locations, quarantine/release, FEFO picking, staged kits, returns and cycle counts |

Inventory Accuracy, FEFO, WMS |

| Weighing & Dispensing Execution | Scale-captured weights, tare controls, container IDs, partials tracking, and operator verification |

Weighing & Dispensing Control, Tare Verification & Container Control, Load Cells & Weighing Systems |

| Issue-to-Order / Charge Events | When and how material becomes “consumed” (issued, weighed, charged, transferred, or backflushed) |

Material Consumption Recording, Work Order Execution, Barcode Validation |

| Reconciliation & Review | Actual vs theoretical consumption, yield variance, exception routing and approvals |

Batch Yield Reconciliation, BRBE, Exception-Based Process Review |

| Hard Gates & Compliance Controls | Preventing wrong-lot use, expired use, tolerance violations, and unapproved substitutions |

Hard Gating, Hold/Release, Deviation Management |

| Governance & Data Integrity | Access control, audit trails, training, change control, and record retention |

User Access Management, Audit Trail, Data Integrity, Management of Change |

2) Why material consumption recording is a high-stakes control (not a bookkeeping preference)

If you run a plant, you already know the uncomfortable truth: most “material usage” problems are discovered late—when inventory is wrong, when a batch fails, when a customer complains, or when an auditor asks a simple question like “show me where lot X was used.” Then everyone scrambles to reconstruct reality.

Material Consumption Recording fixes that by making consumption a first-class manufacturing event. The practical reasons are blunt:

- Traceability is only as strong as consumption capture. You can have pristine receiving records, but if consumption is recorded as “issued 200 kg” without verified lot IDs, you lose downstream genealogy.

- Most investigations start with a lot. In pharma and dietary supplements, a supplier COA or incoming result can trigger targeted checks. Without consumption records, you cannot do a clean impact assessment.

- Yield and potency variances hide in “normal” over-issue. Over-issuing becomes cultural when the system doesn’t force real measurement and reconciliation.

- Regulators and customers expect controlled electronic evidence. If you claim electronic execution, but key consumption steps are “handwritten and later typed,” you’re signalling control weakness.

- Financial posting is not operational truth. ERP backflush can help accounting, but it does not prove what happened on the floor unless execution gates are real.

That’s why consumption recording sits at the intersection of MES, WMS and QMS. You can’t “buy” it as a feature. You have to design it as a workflow that survives real operators, real time pressure, real shift change, and real exceptions.

3) What “consumption” actually means in manufacturing (and where plants fool themselves)

Plants argue about consumption because they mix three different concepts:

- Physical consumption: material is physically removed from a container, weighed/dispensed, and charged into a vessel or used in assembly.

- Operational consumption: material is “committed” to a specific batch or work order (issued, staged, or kitted) and is no longer generally available.

- Financial consumption: inventory is decremented and booked to WIP/COGS in an ERP.

In a weak system, “financial consumption” becomes the proxy for everything else. That’s convenient, but it’s not defensible when the question is: Which lot did you actually use, and did you follow the approved process? An ERP posting doesn’t prove that the correct lot was scanned or that a tolerance gate was passed. It proves someone posted a number.

The goal of Material Consumption Recording is to align these concepts by defining controlled critical events—events where the system records consumption with enough context to be meaningful. Typical consumption events include:

- Scan-to-consume at dispense: consumption recorded when a specific lot is scanned and a net weight is captured from a scale (ideal for weigh & dispense).

- Charge-to-vessel confirmation: consumption recorded when a dispensed container is scanned at the point of addition, confirming the step context.

- Issue-to-order with post-use reconciliation: material issued to a batch with controlled staging, then reconciled based on actual return weights or remaining inventory (common in bulk liquids or large containers).

- Backflush under hard controls: consumption recorded automatically based on measured output or process signals, but only when the upstream identity control is strict and the process is stable.

Pick one blindly and you’ll be wrong. The right model depends on the process. High-risk, high-variability processes need more “point-of-use” verification. Stable, highly automated processes can justify more automation—but the identity chain cannot be weak.

4) How material consumption recording fails in the real world

When consumption records are wrong, it’s rarely because the plant “didn’t care.” It’s because the system design didn’t survive reality. Here are common failure modes we see across regulated manufacturing:

- “Issue equals consume” thinking. The system decrements inventory when material is issued, but the operator only used part of it. The leftovers get “lost,” and the next batch quietly borrows them.

- Blind backflush. Material usage is assumed based on standard BOM without recording actual lot IDs, substitutions, or step-by-step additions.

- Uncontrolled partials. Partially used containers are relabelled by hand, mis-weighed, or returned to the wrong location. Without Tare/Container Control, partials become a traceability black hole.

- UoM chaos. Operators weigh in grams, the BOM is in kilograms, the container label is in pounds, and someone “converts” in their head. If you don’t enforce conversions, you’re begging for variance.

- Lot swapping under pressure. The staged lot is missing, someone grabs “the same item” from another pallet, and the paper record is “fixed later.” That’s how wrong-lot events survive.

- Manual corrections without governance. People adjust inventory or consumption postings to “make the system match,” without controlled reasons, approvals, or a visible audit trail.

- Disconnected quality status. Materials on hold are still physically accessible; consumption happens before release; the system learns about it afterward.

- Equipment state ignored. A scale is out-of-calibration, a barcode scanner is misconfigured, or label templates drift. Without hard gates, bad data becomes normal data.

- Rework and scrap treated as afterthoughts. If rework is added back into a batch, and scrap is removed, but consumption isn’t recorded in-step, your genealogy is broken.

- No step context. The system records “consumed 5 kg of Ingredient A,” but not which step, which phase, or which vessel. That makes investigations painful and variance analysis useless.

Notice the pattern: these are workflow design problems. The fix is not “train harder.” The fix is to design a system where the easiest path is the compliant path—and where deviations are routed explicitly via Deviation Management and Nonconformance Management, not hidden inside “adjustments.”

5) The minimum data you must capture for defensible consumption records

If you want consumption records that support both operations and audits, you need a consistent “consumption transaction” model. At minimum, each consumption event should capture:

- What: item ID + description (from controlled master data).

- Which lot: lot/batch number, plus any sub-lot identifiers (e.g., dispensed container ID).

- How much: gross, tare, net, and unit of measure; plus the conversion basis used.

- Where: location of issue/dispense/charge (warehouse zone, dispensary, line, vessel, room).

- When: timestamp with time zone consistency; and sequence within the process step.

- Who: operator identity; plus any second-person verification if required.

- Why: the step context (work order, operation, recipe step, equipment) and a reason code for any exception.

- How validated: scan evidence, Barcode Validation results, scale capture method (manual entry vs direct integration), and any tolerance checks.

- Status control: material quality status at time of consumption (released/hold/quarantine), linked to Hold/Release.

- Audit trail: who created/edited/approved the transaction and why (Audit Trail and Data Integrity expectations).

That might sound heavy, but it’s what prevents the classic failure: “We have records, but we can’t trust them.” Once you have the model, you can tailor granularity: micro-ingredients may require more strictness; bulk commodities can be controlled through staging and reconciliation. The point is that you can defend your choices because the controls are explicit.

6) End-to-end flow: receiving → quarantine → dispense → consume → reconcile

A reliable consumption model starts before manufacturing ever begins. If you only “turn on” control when the batch starts, you inherit chaos from the warehouse. A practical end-to-end approach looks like this:

7) Receiving and quality status: don’t let “on hand” mean “usable”

First rule: receiving creates inventory; quality disposition creates availability. If you don’t separate those, operators will consume held material because it’s physically present.

- Receive materials into controlled locations and capture lot IDs cleanly at goods receipt (with label standards that support scanning).

- Set default status to quarantine where required, then release via QA/QC. “Released” must be a controlled status, not a verbal approval.

- Enforce FEFO and expiry logic where applicable; if the system allows expired picks, you are building deviations by design.

In regulated plants (especially Pharmaceutical Manufacturing and Dietary Supplements Manufacturing), this is foundational. If quarantine/release is weak, “consumption recording” becomes a forensic exercise later.

8) Picking, staging and kitting: control the “committed” inventory state

Before dispensing, most plants pick and stage materials. This is where “issue-to-order” can be safe if staging is controlled. A mature workflow does the following:

- Directed selection: the system tells the picker which lot to pick, not the other way around.

- Location integrity: materials move via scanned transactions so you can trust where they are.

- Kit identity: staged materials are grouped to a work order with a kit ID; staged lots are visible and auditable.

- Returns discipline: unused staged materials are returned through a controlled return-to-stock process (no “drop it anywhere”).

If you stage without control, you will see two outcomes: stockouts on paper while inventory “exists somewhere,” and operators using the wrong lot because the staged lot doesn’t match what’s on the floor.

9) Weighing and dispensing: where most plants either win or lose

Dispensing is the highest leverage point for consumption integrity, because it’s where identity and quantity can be verified together. A defensible approach uses:

- Step context: dispensing is tied to a specific recipe step and work order (Work Order Execution).

- Lot scanning: the source lot is scanned and validated (Identity Confirmation).

- Container controls: containers have IDs; tare weights are verified (Tare Verification).

- Scale capture: weights are captured from the scale (not typed), with appropriate rounding rules and tolerance checks.

- Labeling discipline: dispensed containers are labelled with item/lot/quantity/container ID and linked back to the source lot.

This is where Paperless Dispensing becomes a control strategy, not a tech buzzword. Paper processes can work, but only if you can guarantee that what’s written is what happened. Most plants cannot. Electronic capture reduces ambiguity and enables Batch Review by Exception because the system can automatically detect out-of-tolerance events.

10) Charging and in-process additions: don’t let dispensed material become “free-floating”

Dispensing is not the end. If a dispensed container sits on a bench and gets used in the wrong batch, your records still fail. A robust workflow adds a second confirmation at the point of use:

- Scan the dispensed container ID at the vessel/line to confirm the correct batch context.

- Confirm step sequence (no “we’ll add it later” unless the process allows it and the deviation is controlled).

- Record partial usage of a dispensed container explicitly—remaining quantity stays linked to the container ID and is either consumed later in the same batch (controlled) or returned (controlled).

For high-risk industries like Medical Device Manufacturing, the same principle applies to component usage: once components are picked/issued, they must be consumed to an order in a traceable way—especially when device history records and complaints depend on part genealogy.

11) Scrap, rework, and returns: consumption is not a one-way street

Plants lose control when they treat scrap and rework as side notes. In reality:

- Scrap removal must be recorded with quantities, reasons, and approvals—otherwise yield variances look like “mystery loss.”

- Rework additions must be treated like consumption: identify the rework lot, verify its status, and record how much is added to which batch.

- Returns-to-stock must preserve identity and status. Returning a partial without recording weight and container ID creates inventory fiction.

If you want consumption integrity, you need the full loop: consume → reconcile → return/scrap/rework with controlled evidence.

12) Hard gates and exception workflows: the controls that stop “creative manufacturing”

Most plants don’t fail because they lack procedures. They fail because the system allows a bad action and then asks people to self-report it. If you want reliable Material Consumption Recording, you need Hard Gating at the moments that matter. Examples:

| Risk event | What the system should do | How it’s resolved |

|---|---|---|

| Wrong item scanned | Block consumption; show mismatch against recipe step/BOM | Use the correct item or raise approved substitution/change control |

| Wrong lot scanned | Block consumption; enforce Lot Assignment rules | Pick the directed lot or execute a controlled lot swap with approval |

| Material on hold/quarantine | Block consumption; prevent “use before release” | Complete QA disposition (Hold/Release) |

| Expired/FEFO breach | Block pick/consume; force FEFO selection | Use FEFO lot; if exception allowed, log deviation and approval |

| Out-of-tolerance weight | Warn/Block based on criticality; require reweigh or adjustment | Correct to target; if accepted, route to Deviation |

| Manual weight entry attempted | Restrict or require second-person verification | Enable only for defined exception scenarios with audit trail |

| Scale out-of-calibration | Block use of the scale; prevent new transactions | Use a qualified scale; route maintenance/calibration actions |

The “tell it like it is” point: if your system can’t stop wrong-lot use in the moment, you do not control consumption. You are hoping people behave under pressure. Hope is not a control strategy.

13) Reconciliation: where consumption records become either evidence or embarrassment

Even with strong execution, reconciliation is where you prove the record is complete. Batch Yield Reconciliation connects theoretical usage (what the recipe expected) to actual usage (what the floor recorded) and then to output (what you actually made). Done well, reconciliation is not a monthly accounting exercise; it’s a batch release readiness check.

Practical reconciliation questions that your system should answer quickly:

- Over/under consumption: Which components exceeded tolerance bands? Were they approved? Were they corrected or justified?

- Unconsumed issues: What was issued/staged but not consumed? Was it returned? If not, why not?

- Unplanned components: Were any non-BOM items consumed? If yes, what change control or deviation authorized it?

- Lot completeness: Can you list all source lots used in the batch, including rework lots and partial containers?

- Timing/sequence: Were additions performed in the required order (where sequence matters)?

This is the logic behind Batch Review by Exception. If the system captures consumption with step context and automated checks, review becomes targeted: you review exceptions, not every line item. If consumption is captured as a summary number at the end, review becomes “read and hope.”

14) Industry realities: the same control, different pain points

Consumption recording is universal, but the failure modes and priorities differ by industry. The control strategy should reflect the actual risks, not a one-size-fits-all template.

Pharmaceutical Manufacturing (industry overview): consumption records are part of your batch record and release story. Wrong-lot or wrong-quantity events can trigger deviations, investigations, and potentially product quality impact assessments. Here, step-level identity verification and electronic evidence aligned with Part 11/Annex 11 matter. “We used the right thing” is not enough; you must show how you prevented using the wrong thing.

Dietary Supplements (industry overview): you get variability, micro-ingredients, and label claim sensitivity. Dispensing errors can translate into potency failures, label misstatements, and costly holds. Tight weigh & dispense control, strong partials handling, and clean reconciliation are non-negotiable if you want to avoid “blend and pray.”

Food Processing (industry overview): consumption recording is the backbone of allergen management, mass balance, and recall readiness. If you can’t prove which lots went into which finished goods lots, you’ll over-recall and burn margin. Even when regulations don’t force electronic records, customers and auditors will. This is where lot genealogy (end-to-end traceability) becomes business protection, not just compliance.

Ingredients & Dry Mixes (industry overview): powders amplify consumption problems. Dusting losses, rework loops, and bulk handling can create “inventory drift.” Strong staging discipline, container IDs, and reconciliation tied to actual scale weights prevent the slow death of inventory truth.

Cosmetics Manufacturing (industry overview): consumption recording drives batch consistency, complaint investigations, and ingredient compliance. Even when the regulatory frame differs from pharma, the operational need is the same: if a fragrance lot triggers complaints, you must identify where it was used. “We think it was in those batches” is not acceptable.

Agricultural Chemical Manufacturing (industry overview): consumption must account for hazardous materials, potency adjustments, and strict segregation rules. Substitutions and concentration corrections need explicit approval routes and complete audit trails. A weak consumption model can become a safety and compliance liability.

Plastic Resin Manufacturing (industry overview): you’re often dealing with bulk materials, silos, feeders, regrind, and masterbatch dosing. Consumption can be automated, but only if the process instrumentation is integrated and the identity chain (which silo, which lot, which feeder) is controlled. Otherwise you get “it came from the system” records that can’t withstand root-cause analysis when defects appear.

Consumer Products (industry overview): high SKU variety and packaging complexity mean consumption recording must cover both ingredients and packaging components. If packaging consumption isn’t captured accurately, you can’t reconcile yields, you can’t control line losses, and you can’t explain label/artwork usage in investigations.

Bakery Manufacturing (industry overview): flour, water, and minor ingredients create continuous variance. That’s exactly why consumption capture matters: you can’t improve yield or consistency without knowing whether the plant is over-dosing, reworking, or bleeding losses.

Sausage & Meat Processing (industry overview): variable raw materials and catch-weight realities make consumption recording tricky. If you don’t capture actual weights and lot linkages, you can’t do a credible trace or reconcile yields. “Standard usage” assumptions collapse when raw input variability is high.

Produce Packing (industry overview): “materials” often include packaging components (clamshells, cartons, labels) and sometimes additives. Consumption recording supports order integrity and label control. If you can’t reconcile packaging usage, you can’t explain shrink and you can’t prove label control when customers challenge you.

All of these industries sit under the same umbrella: you need an execution record of what you used, not a financial guess of what you should have used. The more regulated the sector, the less tolerance there is for ambiguity.

15) System architecture: MES + WMS + QMS (and why “just ERP” doesn’t cut it)

In a modern plant, consumption recording is a cross-system capability. Here’s the straight story:

- ERP is good at inventory valuation and financial posting. It is not designed to enforce step-level execution, scan validation, or real-time gating on the shop floor.

- WMS controls where inventory is and what lot is available to pick. Without WMS discipline, consumption records are built on shifting sand.

- MES controls the work order, recipe steps, and the moment of consumption. This is where identity checks, tolerance checks, and step context should live.

- QMS governs the “why”: deviations, nonconformances, CAPAs, training, and controlled changes that justify exceptions and prevent repeat failures.

To make consumption records defensible, these systems must share a common truth: item masters, lot identities, status controls, and audit evidence. If you leave the floor to paper and only post “usage” later, you are creating a data integrity problem. And if you bolt on scanning without hard gates, you are creating a theatre of control: it looks modern, but it doesn’t prevent wrong actions.

16) How V5 implements material consumption recording in practice

SG Systems Global’s V5 platform implements Material Consumption Recording as a controlled workflow across MES, WMS, and QMS—so consumption events are captured with context, validated in real time, and reviewable without manual reconstruction.

- V5 MES. The V5 MES layer:

- Executes work orders and recipe steps with enforced sequence where needed.

- Enforces recipe & parameter rules, including component lists, tolerances, and approved substitutions.

- Captures consumption as step-linked transactions (scan + weigh + context), supporting paperless dispensing and verified charge events.

- Applies hard gates for wrong lot, wrong item, hold status, expiry/FEFO, and out-of-tolerance weights.

- V5 WMS. The V5 WMS layer:

- Controls lot and location truth, improving inventory accuracy by requiring scan-based movements.

- Supports directed picking, FEFO selection, staging/kit IDs, and controlled returns to stock.

- Maintains the lot genealogy chain so consumption records link upstream to receiving and QA status.

- V5 QMS. The V5 QMS layer:

- Routes consumption exceptions into deviations or nonconformances instead of “silent adjustments.”

- Supports CAPA linkages so recurring consumption issues are addressed structurally.

- Aligns training and access control with roles (training matrix, UAM), supporting data integrity expectations.

- V5 Connect API. The V5 Connect API:

- Integrates scales, scanners, label printers, PLC signals, and shop-floor devices so “weights” are captured, not typed.

- Supports controlled data capture that improves audit trail defensibility and reduces manual data integrity risk.

Implementation note: V5 doesn’t treat “consumption recording” as a report. It treats it as execution. That’s why it supports BRBE: the system can automatically surface what actually needs review, because the underlying events are structured and validated.

If you want a broader overview of how these layers fit together across MES/WMS/QMS, see V5 Solution Overview and the industries hub at Industries.

17) KPIs that prove your consumption recording is working (or expose that it isn’t)

Good KPI design focuses on leading indicators (process control) and lagging indicators (outcomes). Here are practical metrics that show whether Material Consumption Recording is real:

- Consumption capture completeness. % of work orders with 100% step-linked consumption transactions recorded (no “summary-only” usage).

- Wrong-lot prevention rate. Count of prevented wrong-lot scans (a good number early on; it proves the gate works).

- Manual entry rate. % of weights entered manually vs captured from integrated scales (manual should trend toward near-zero).

- Out-of-tolerance events per batch. Frequency by component and by line (high = process instability or weak training).

- Over-issue variance. Actual issued vs theoretical by component; track persistent over-issue as margin leakage.

- Return-to-stock cycle time. Time from batch close to completing returns, so staged materials don’t “linger.”

- Partial container accuracy. % of partial containers with verified remaining weight at return; track “unknown partials.”

- Inventory reconciliation delta. Count and value of inventory adjustments tied to consumption discrepancies.

- Batch review closure time. Time from last step completion to release-ready record (BRBE works when this drops).

- Exception resolution quality. % of exceptions routed with correct reason codes and approvals (not “other/unknown”).

- Repeat deviation rate. Recurrence of the same consumption-related deviation after CAPA closure (should drop).

- FEFO compliance. % of picks/consumptions using FEFO-directed lots (especially critical for expiry-driven materials).

If you can’t measure these, you are not controlling the process—you are measuring outputs and guessing causes.

18) Common pitfalls: why “we installed scanning” still doesn’t give you control

- Scanning without enforcement. If the operator can bypass a mismatch, the system becomes optional.

- ERP-led backflush with weak identity control. “Standard usage” does not equal traceability.

- Uncontrolled substitutions. Substitutions happen; pretending they don’t is how they become invisible.

- No container identity. Without container IDs, partials are untraceable and rework loops break genealogy.

- Too many manual adjustments. Inventory “fixes” that aren’t tied to controlled root causes are data integrity debt.

- UoM conversions left to humans. This is how you get silent 10× errors that nobody catches until release testing fails.

- Quality status not enforced physically. If held material is accessible, it will be used; the record will be “corrected later.”

- Step context missing. Recording consumption without operation/step makes investigations slow and variance analysis shallow.

- Scale integration ignored. Typing weights is an invitation to transcription error and “helpful rounding.”

- Exception workflows too hard. If raising a deviation takes 30 minutes, people will route around it.

- Training not linked to access. If anyone can approve overrides, you don’t have role-based control.

- Change control too slow for master data. If BOM updates lag reality, operators will improvise—and records will follow the improv.

19) Quick-start checklist: strengthening material consumption recording in 30–60 days

- Define what event counts as “consumption” for each process family (dispense, charge, issue, backflush) and document it as the standard.

- Standardise labels so every material lot is scannable and unambiguous (barcode validation rules).

- Enforce lot-level selection and FEFO rules for expiry-driven materials (FEFO).

- Implement controlled staging/kit IDs so “issued” materials remain traceable to a specific order.

- Deploy dispensary workflows where source lot scanning and scale capture are mandatory for critical materials.

- Introduce container IDs and tare verification for all partials (tare & container control).

- Block consumption of materials in quarantine/hold status via system gating (hold/release).

- Define tolerance bands per component and step; enforce them with alerts or blocks depending on risk.

- Create reason codes that match reality (over-issue due to dusting, line loss, transfer loss, etc.)—and require them.

- Route wrong-lot and out-of-tolerance events into controlled deviation workflows (deviation management).

- Set rules for manual entry: when allowed, who approves, and how it’s recorded with audit trail.

- Integrate scales where possible so weights are captured, not typed.

- Implement a return-to-stock workflow that requires verified remaining quantity and location scan.

- Define how rework is created, labelled, status-controlled, and consumed back into batches.

- Implement reconciliation checkpoints before release: unreturned issues, unapproved substitutions, missing scans.

- Adopt BRBE logic: review exceptions, not every line—only possible if the data is structured.

- Link training requirements to role permissions (training matrix + UAM).

- Apply change control to BOM/recipe edits so “what was supposed to happen” stays aligned with “what operators do.”

20) Material Consumption Recording FAQ

Q1. Is “issue to batch” the same as consumption?

No. Issue is a commitment event; consumption is a use event. Issue can support control when staging is strict and returns are reconciled, but it does not prove that the issued lot was the lot actually used. For high-risk components, you typically need scan + weigh at dispense or charge.

Q2. Can we use backflush and still have audit-ready consumption records?

Sometimes, but only when the identity chain is strong and the process is stable. Backflush without verified lot identity and exception governance is an accounting convenience, not an execution record. If the plant makes substitutions, uses partials, or has variable losses, blind backflush will fail investigations.

Q3. How granular should consumption recording be—per batch, per step, or per addition?

Start with risk. Critical actives, allergens, and micro-ingredients should be recorded at the step/addition level. Bulk base materials may be controlled through issue + controlled staging + reconciliation, but you still need lot IDs and verified quantities. The rule of thumb: if a mistake has high impact, record it at the moment it can be prevented.

Q4. How do we handle partial containers without losing traceability?

Treat partials as uniquely identified assets: container ID, verified tare, remaining net weight, and a controlled return-to-stock location. Never allow “open partials” to float without identity. Most traceability collapses because partials are unmanaged.

Q5. What do auditors look for in electronic consumption records?

Consistency and control: identity verification evidence, clear link to approved recipe/step, audit trails for changes, clear approvals for exceptions, and proof that the system prevents bad actions rather than just recording them. If the record is “editable until it looks right,” it won’t hold up.

Q6. How does strong consumption recording reduce release cycle time?

It enables review by exception. When consumption is captured as structured, validated events, the system can automatically flag only what needs attention—out-of-tolerance weights, wrong-lot attempts, manual entries, and unreturned issues. That shortens batch record review and reduces late surprises.

Related Reading

• Industries: Industries Hub | Pharmaceutical Manufacturing | Dietary Supplements | Food Processing | Ingredients & Dry Mixes | Cosmetics | Agricultural Chemicals

• Products: V5 MES | V5 WMS | V5 QMS | V5 Connect API | V5 Solution Overview

• Glossary: Material Consumption Recording | Weigh & Dispense Automation | Material Identity Confirmation | Material Lot Assignment | Batch Yield Reconciliation | BRBE | Hard Gating | Data Integrity | Audit Trail

OUR SOLUTIONS

Three Systems. One Seamless Experience.

Explore how V5 MES, QMS, and WMS work together to digitize production, automate compliance, and track inventory — all without the paperwork.

Manufacturing Execution System (MES)

Control every batch, every step.

Direct every batch, blend, and product with live workflows, spec enforcement, deviation tracking, and batch review—no clipboards needed.

- Faster batch cycles

- Error-proof production

- Full electronic traceability

Quality Management System (QMS)

Enforce quality, not paperwork.

Capture every SOP, check, and audit with real-time compliance, deviation control, CAPA workflows, and digital signatures—no binders needed.

- 100% paperless compliance

- Instant deviation alerts

- Audit-ready, always

Warehouse Management System (WMS)

Inventory you can trust.

Track every bag, batch, and pallet with live inventory, allergen segregation, expiry control, and automated labeling—no spreadsheets.

- Full lot and expiry traceability

- FEFO/FIFO enforced

- Real-time stock accuracy

You're in great company

How can we help you today?

We’re ready when you are.

Choose your path below — whether you're looking for a free trial, a live demo, or a customized setup, our team will guide you through every step.

Let’s get started — fill out the quick form below.