Meat Processing Software — Traceability of Meat Products, GS1-128 Meat Labeling & BRCGS Controls in One System

This topic is part of the SG Systems Global regulatory & operations glossary.

Updated November 2025 • meat processing software, meat processing system, meat traceability software, GS1-128 meat labeling, BRCGS Issue 9, Walmart SQEP meat category • Red Meat, Poultry, Sausage & Deli, Further Processing

Meat processing software is the integrated platform that runs a modern meat plant: intake, deboning, grind and mix, smokehouse and thermal processing, slicing and packing, catch-weight traceability, cold storage, and outbound logistics. A true meat processing system does more than count boxes; it enforces identity, status and quantity at every step, delivers full traceability of meat products and supports standards such as BRCGS meat processing controls Issue 9 and Walmart SQEP requirements meat category.

When people talk about “meat traceability software”, “meat processing systems” or a “meat traceability system in the supply chain”, this is what they mean in practice: a single, enforced model of how raw material, batches, labels and loads move through the plant and into the market.

“If you can’t answer which supplier lot, which combo, which grind, which mixer, which smokehouse load, which label, which pallet, which customer—from your meat processing software—you don’t have a system. You have forklifts and spreadsheets.”

1) Why meat processing software now — hard truths

- Variable weight is the norm, not the exception. Carcasses, primals, trim, chubs and cases are all variable-weight. If your meat processing system can’t handle catch-weight and mass balance, your costing and traceability both leak.

- Retailers expect proof, not promises. Programs like Walmart SQEP requirements meat category and Costco supplier food safety requirements demand reliable data on labels, codes, weights and foreign-material controls.

- Regulatory bar keeps rising. FSIS 9 CFR 417 HACCP, Appendix A/B, BRCGS meat processing controls Issue 9, SQF Edition 9 mass balance and export schemes all assume robust, auditable traceability of meat products.

- Multi-site and co-processing are normal. Trim may be processed in one plant, cooked in another, sliced and packed in a third and warehoused by a 3PL. Meat processing software must maintain one chain across all of it.

- Margin is under pressure. Over-scoping a recall because your meat traceability software is weak can erase a year’s profit. Precision and speed both matter.

2) What meat processing software covers

| Area | What the system controls | Glossary anchors |

|---|---|---|

| Intake & Live/Raw Material | Suppliers, kill/fabrication plants, combo IDs, species & programs | GS1-128 Raw Material Intake Labeling, COO |

| Deboning & Trim Streams | Carcass breakdown, primals, trim and fat streams, combo management | Catch-Weight Traceability |

| Grinding & Mixing | Grind batches, lean/fat targets, seasoning & functional additions | Automated Spice & Functional Additive Batching, Sequenced Ingredient Weighing |

| Smokehouse & Thermal | Load formation, time/temperature profiles, lethality & cooling data | Mixer-to-Smokehouse Load Validation, Appendix A, Appendix B |

| Packaging & Catch-Weight | Chubs, trays, MAP packs, cooked weights, label data, variable weight | Packaging Line Catch-Weight Integration, Chub ID & Weight Tracking |

| GS1-128 Meat Labeling | GTIN, lot, weight, dates, program codes, SSCC pallets | GS1-128 Case Label, SSCC |

| Cold Storage & WMS | Batch-to-bin mapping, FEFO, route picking, load building | Batch-to-Bin Traceability, Warehouse Locations |

| Foreign-Material & Quality | Metal/X-ray performance, bone detection, QA holds & releases | Metal Detector Verification Tests, X-Ray Bone Fragment Detection Validation |

| Traceability & Recalls | End-to-end lot genealogy, one-up/one-down, mock recall tools | End-to-End Lot Genealogy, One-Up / One-Down Traceability, Mock Recall Performance |

| Compliance & Retail Programs | BRCGS Issue 9 meat controls, SQF, Walmart SQEP, customer codes | BRCGS Meat Processing Controls Issue 9, Walmart SQEP Requirements Meat Category |

| Data Integrity & Integrations | Users, audit trails, retention, links to ERP, LIMS, QMS, scale & label systems | Data Integrity, MES, WMS |

3) Intake & raw material identity — first step in traceability of meat products

Any serious meat processing system starts at intake. That’s where lot identity, programs and catch-weight enter the supply chain.

- Combo and carcass tracking. Live animals, primals and combos are captured with supplier, establishment number, kill/fab plant and COA data. IDs are carried via GS1-128 raw-material intake labeling.

- Program segregation. Organic, grass-fed, breed, religious and export programs are tagged at intake so meat traceability software can police mixing downstream.

- Catch-weight foundation. Actual weights of combos and bins form the starting point for catch-weight traceability; later batches and packs reconcile back to this base.

- Hold/release. Incoming lots can be placed on QA hold pending micro or residue results; integration with LIMS and QMS ensures only released lots feed production.

If meat processing software loses the thread here, every downstream “traceability of meat products” claim is built on sand.

4) Grinding, mixing & catch-weight — where meat processing systems often fail

Grind and mix stages make or break a meat traceability system in the supply chain. This is where multiple lots are blended and where small leaks in genealogy become big gaps later.

- Trim and fat genealogy. Every trim and fat addition is scanned into a grind batch. The system records which catch-weight totes fed each lot.

- Automated seasoning and functional batching. Automated spice & functional additive batching keeps curing agents, phosphates, binders and water additions under tight weight and sequence control.

- Sequenced ingredient weighing. Salt–protein–ice sequencing and other recipe logic are enforced by meat processing software during batching.

- Batch yield reconciliation. Batch yield reconciliation compares trim issued to finished batches, rework and declared loss, closing the mass-balance loop.

Good meat processing software turns “we think those combos went into that mixer” into deterministic genealogy down to the kilogram.

5) Smokehouse loads, lethality & cooling — risk, recorded

For cooked sausages, deli and smoked products, thermal processing is a critical hazard. Meat processing software links product genealogy to thermal records:

- Load formation & validation. Mixer-to-smokehouse load validation records which batches and racks are loaded into each cell or truck. Smokehouse load verification scanning confirms no stray racks sneak in.

- Time/temperature profiles. Time, core temperature and humidity curves are tied to specific loads for Appendix A lethality and Appendix B stabilization.

- Post-smoke labeling and transfers. Post-smokepath GS1-128 re-labeling ensures product identity survives re-bagging, slicing or recasing operations.

If a validation study or in-plant deviation flags a thermal profile, the meat processing system should immediately list all lots, cases and customers affected.

6) Packaging, catch-weight & GS1-128 meat labeling

Packaging is where customers and inspectors see whether your meat traceability software works in the real world.

- Packaging-line catch-weight integration. Packaging line catch-weight integration connects scales and labelers so every tray, bag or chub carries accurate weight and price while maintaining lot identity.

- Chub ID and cooked-chub verification. Chub ID & weight tracking and cooked-chub weight verification enable unit-level traceability where required.

- GS1-128 meat labeling. Cases are labeled with GS1-128 case labels carrying GTIN, lot, weight, pack date and other encoded data. Pallets carry SSCC IDs.

- Customer-specific data. Meat processing software supports customer-specific label fields and SSCC structures demanded by big retailers and food-service operators.

When a GS1-128 case label is scanned in the field, it should decode all the way back through the meat processing system to intake lots, processing steps and thermal records.

7) Foreign material, metal/X-ray & BRCGS meat processing controls

BRCGS meat processing controls Issue 9 and retailer programs put heavy emphasis on foreign-material management. Meat processing software should make these requirements routine:

- Metal detector verification tests. Metal detector verification tests (3 mm / 4 mm) are scheduled, logged and tied to specific lines and products.

- X-ray bone detection validation. X-ray bone fragment detection validation studies and routine performance checks are managed as QMS records linked to lots and SKUs.

- Reject tracking & holds. Rejects from metal/X-ray equipment trigger events in the meat processing system: lots can be held, inspected and either released or downgraded with full documentation.

Foreign-material events then sit inside the same genealogy as everything else—no separate, unlinked logbook.

8) Cold store, WMS & meat traceability system in the supply chain

A meat processing system doesn’t stop at the plant door. Cold storage and distribution are part of the same chain:

- Batch-to-bin mapping. Batch-to-bin traceability shows exactly which pallets sit in which freezer, rack and slot—on site or at 3PLs.

- FEFO and route planning. FEFO logic ensures oldest and high-risk product ships first, while route building takes customer specs and temperature constraints into account.

- One-up / one-down traceability. The system provides one-up / one-down traceability across the supply chain, as expected by USDA and global programs.

- Integration with ERP and EDI. Pallet IDs, GS1-128 case IDs and customer orders tie directly into ERP and EDI/ASN flows so commercial and physical traces match.

This is where “meat traceability software” becomes “meat traceability system in the supply chain”, not just inside four walls.

9) Traceability of meat products & mock recalls

The real test of meat processing software is how it behaves during a recall, withdrawal or investigation:

- Upstream trace. From a consumer pack, case label, pallet, load or complaint, the system should show which combs, trim lots, seasoning and smokehouse loads are in scope.

- Downstream exposure. From a suspect supplier lot, process deviation or detection failure, it should list all affected products, cases, loads and customers.

- Mock recall performance. Mock recall performance metrics (time to identify scope, accuracy of customer lists, mass-balance closure) provide an objective measure of how good your meat processing system really is.

With strong traceability of meat products, recall scope can be tightly targeted and backed by data instead of guesswork.

10) Implementation playbook — choosing and rolling out meat processing software

- Map your current flows. Document intake, deboning, grind/mix, thermal, packaging, warehousing, distribution and returns for each site.

- Stabilise IDs and labels. Standardise lot IDs, GS1-128 formats and SSCC structures across plants and 3PLs; get rid of local coding quirks.

- Instrument high-risk steps first. Focus on grind/mix, smokehouse, packaging, foreign-material control and cold store batch-to-bin before tackling everything else.

- Connect to existing ERP & QMS. Use APIs or integration tools so orders, costs and quality data line up with what the meat processing software sees on the floor.

- Train via mock recalls. Use realistic recall drills to train people on the new system and prove that meat traceability software delivers under pressure.

11) How people talk about meat processing software (and what this page covers)

Different teams search for or describe the same capability in different ways: meat processing software, meat processing system, meat processing systems, meat traceability software, meat traceability system, traceability of meat products, GS1-128 meat labeling or “meat traceability system in supply chain”. The underlying goal is the same: one platform that connects raw-material identity, batch execution, labels, pallets and customers with regulatory and retailer expectations such as BRCGS meat controls and Walmart SQEP.

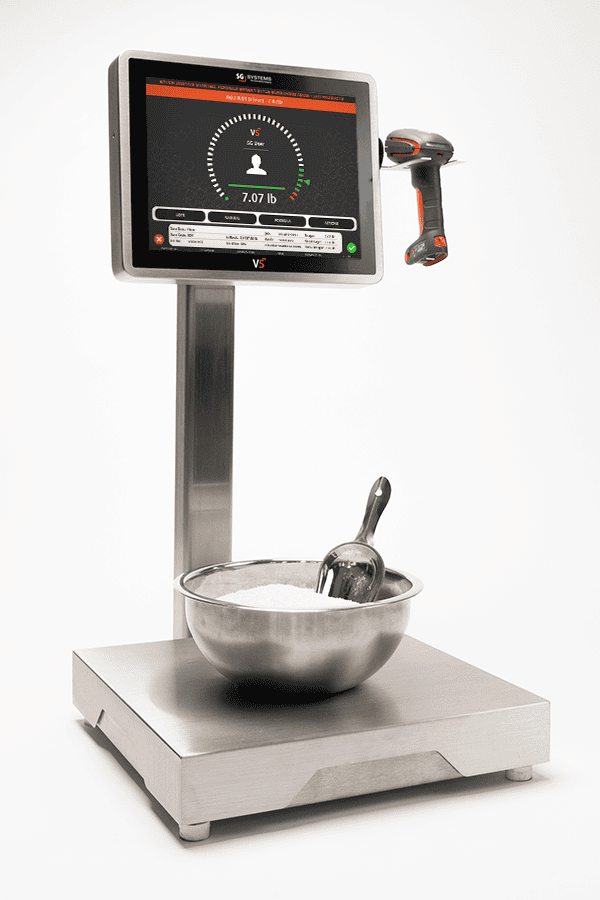

12) How this maps to V5 by SG Systems Global

V5 Traceability from SG Systems Global is designed to operate as comprehensive meat processing software:

- Execution & batching. V5 MES manages grind/mix batching, automated spice & functional additive batching, sequenced ingredient weighing and mixer-to-smokehouse load validation, building enforced genealogy in the background.

- Warehouse & logistics. V5 WMS handles GS1-128 meat labeling on cases, SSCC pallets, batch-to-bin tracing and route picking.

- Quality & compliance. V5 QMS manages deviations, foreign-material events, mock recalls and CAPA, aligned with BRCGS, SQF and retailer programs.

- Integration. The V5 Connect API allows ERP, LIMS, label print engines and business-intelligence tools to plug into the same meat traceability spine.

Combined, these modules give processors a single meat processing system that covers operations, traceability of meat products and compliance expectations from plant to customer.

13) KPIs that show meat processing software is doing its job

- Traceability coverage: % of shipped volume with complete, lot-level genealogy from intake combo to customer load.

- Mock recall time: minutes from trigger (supplier lot, process deviation, complaint) to finished list of affected products and customers.

- GS1-128 / SSCC compliance: % of cases and pallets meeting retailer-specific GS1-128 meat labeling and SQEP requirements.

- Mass-balance closure: % of grind/mix batches where intake vs. output + rework + loss reconciles within defined tolerances.

- Foreign-material linkage: % of metal/X-ray events linked to specific lots and loads in the genealogy.

- Untraceable units: count of pallets/cases that cannot be traced upstream/downstream within the recall SLA (target: zero).

14) Common pitfalls meat processing software should prevent

- Combo numbers on a whiteboard. Intake IDs tracked informally, not in the system, breaking upstream genealogy.

- Excel as the main traceability tool. Grind/mix, smokehouse and packaging records scattered across spreadsheets with no audit trail.

- Partial GS1 adoption. Some customers get GS1-128 meat labels, others get internal codes only, forcing manual mapping during recalls.

- Unlogged rework and leakers. Rework streams not captured as distinct lots, making true traceability of meat products impossible.

- No regular recall drills. Mock recalls never exercised, so people only learn how the system works during a real crisis.

15) Extended FAQ — Meat Processing Software

Q1. What is meat processing software?

Meat processing software is an integrated set of tools that runs intake, production, packaging, warehousing and traceability for meat and poultry plants. It combines production control, WMS, label management and meat traceability software into one platform.

Q2. How is a meat processing system different from generic ERP or WMS?

ERP focuses on orders and finance; a generic WMS focuses on inventory locations. A meat processing system understands combos, trim streams, catch-weight, grind batches, smokehouse loads, GS1-128 meat labeling, foreign-material controls and regulatory programs such as BRCGS Issue 9 and SQF.

Q3. What is meat traceability software?

Meat traceability software is the part of meat processing software that builds and queries lot-level genealogy across intake, grind/mix, thermal processing, packaging, cold storage and distribution so that recalls and investigations can be done quickly and precisely.

Q4. Why is GS1-128 meat labeling important?

GS1-128 case labels and SSCC pallet IDs standardise how product identity and traceability data are encoded on labels, making it easier to exchange data with retailers, distributors and 3PLs and to run precise recalls.

Q5. Can meat processing software support multiple plants and 3PL cold stores?

Yes. Modern systems are designed as multi-site platforms, tracking lots and pallets across plants, 3PL warehouses and routes while maintaining a single meat traceability system in the supply chain.

Q6. How does meat processing software help with BRCGS meat processing controls Issue 9?

It provides electronic records and enforcement for key BRCGS clauses: mass balance, foreign-material management, label and coding control, equipment and line verification, and full traceability of meat products from raw material to despatch.

Q7. Is meat processing software only for large plants?

No. Smaller processors and specialty sausage or RTE producers also benefit from integrated meat processing systems, especially when serving export markets or retailer programs with strict data and traceability expectations.

Q8. What is the minimum viable meat processing system?

At minimum: controlled lot IDs and GS1-128 meat labeling, scan-based intake and packaging, basic grind/mix and smokehouse genealogy, batch-to-bin cold-store mapping, and a simple recall tool that can answer “where did this lot go?” and “what was in this case?” within hours.

Related Reading

• Meat & Sausage Controls: BRCGS Meat Processing Controls Issue 9 | FSIS Appendix A | FSIS Appendix B | Walmart SQEP Requirements Meat Category

• Traceability & Labeling: Traceability (End-to-End Lot Genealogy) | One-Up / One-Down Traceability | GS1-128 Case Label | SSCC

• Foreign Material & Yield: X-Ray Bone Fragment Detection Validation | Metal Detector Verification Tests | Batch Yield Reconciliation

OUR SOLUTIONS

Three Systems. One Seamless Experience.

Explore how V5 MES, QMS, and WMS work together to digitize production, automate compliance, and track inventory — all without the paperwork.

Manufacturing Execution System (MES)

Control every batch, every step.

Direct every batch, blend, and product with live workflows, spec enforcement, deviation tracking, and batch review—no clipboards needed.

- Faster batch cycles

- Error-proof production

- Full electronic traceability

Quality Management System (QMS)

Enforce quality, not paperwork.

Capture every SOP, check, and audit with real-time compliance, deviation control, CAPA workflows, and digital signatures—no binders needed.

- 100% paperless compliance

- Instant deviation alerts

- Audit-ready, always

Warehouse Management System (WMS)

Inventory you can trust.

Track every bag, batch, and pallet with live inventory, allergen segregation, expiry control, and automated labeling—no spreadsheets.

- Full lot and expiry traceability

- FEFO/FIFO enforced

- Real-time stock accuracy

You're in great company

How can we help you today?

We’re ready when you are.

Choose your path below — whether you're looking for a free trial, a live demo, or a customized setup, our team will guide you through every step.

Let’s get started — fill out the quick form below.