Traceability in Manufacturing — End-to-End Lot Genealogy Across Regulated Industries

This topic is part of the SG Systems Global regulatory & operations glossary.

Updated November 2025 • Traceability in Manufacturing, batch genealogy, one-up/one-down, FSMA 204, DSCSA, UDI, CPSR/PIF, BRCGS/SQF • Pharma, Medical Devices, Food & Meat, Bakery, Dietary Supplements, Cosmetics, Agricultural Chemicals, Plastic & Resin, Ingredients & Dry Mixes, Consumer Products, Produce Packing

Traceability in manufacturing is the ability to follow materials, intermediates and finished goods forward and backward through every step of production and the supply chain. In practice, that means connecting supplier lots, recipes, equipment, line events, quality decisions, labels, pallets, customers and—in many industries—patient or consumer outcomes. For regulated sectors such as pharmaceuticals, medical devices, food, dietary supplements and cosmetics, traceability in manufacturing is not just operational good sense; it is an expectation embedded in regulations, standards and customer codes of practice.

Different industries call it different things: end-to-end lot genealogy, one-up / one-down traceability, produce traceability, DSCSA serialisation, UDI, FSMA 204 KDE/CTE, PIF history—yet the underlying pattern is the same: a digital thread that makes it clear what happened, when, where, with which material and under whose decision.

“Traceability in manufacturing is what turns a batch record, label or pallet tag into a story: where it came from, what happened to it, and who might be affected when something goes wrong.”

1) What “Traceability in Manufacturing” really means

At its core, traceability in manufacturing is the combination of three capabilities:

- Identification. Everything that matters—materials, intermediates, batches, units, pallets, locations, equipment, test plans—has a unique, unambiguous identifier, often encoded in barcodes or serialisation IDs.

- Genealogy. Relationships between those identifiers are captured in a structured way: which incoming lots fed which batches, which batches filled which containers, which pallets went to which customers. This is the batch genealogy or lot-genealogy graph.

- Context. Each node in the graph carries relevant context—recipe version, process parameters, CPPs, test outcomes, deviations, approvals—so that traceability isn’t just “where it went” but also “how it behaved” and “why it was accepted.”

Traceability in manufacturing becomes powerful when this graph spans multiple systems (ERP, MES, LIMS, WMS, QMS) and multiple sites, without relying on hero spreadsheets.

2) Core building blocks of a manufacturing traceability system

| Building block | What it controls | Glossary anchors |

|---|---|---|

| Identification & Labelling | Lots, batches, serials, barcodes, RFID, UDI, GS1-128, PTI | Serialization, GS1-128 Case Label, PTI, UDI |

| Lot Genealogy | Links between incoming lots, intermediates, finished goods and customers | End-to-End Lot Genealogy, Batch Genealogy, One-Up / One-Down Traceability |

| Process Context | Recipes, CPPs, in-process controls, deviations, approvals | Recipe & Parameter Enforcement, IPC, Deviations/NC |

| Quality & Lab Data | Sampling, test results, stability, micro, release decisions | LIMS, Hold/Release, CPV |

| Warehouse & Logistics | Locations, FEFO, pallets, routes, returns and RMAs | Batch-to-Bin Traceability, Returns & RMA |

| Compliance & Records | Regulatory expectations, GxP/GFSI schemes, audits, record retention | Data Integrity, Record Retention & Archival |

3) Traceability in pharmaceutical manufacturing

In pharmaceutical manufacturing, traceability is baked into 21 CFR 210/211 and ICH guidance:

- Batch records & genealogy. The BMR/eBMR must show each material lot, equipment set-up, step, IPC and deviation that contributed to the batch.

- DSCSA serialisation. The Drug Supply Chain Security Act (DSCSA) extends traceability beyond the plant: unit, case and pallet serialisation, transaction records and verification across the supply chain.

- Lab integration. LIMS results (identity, potency, impurities, micro) must link back to specific batches, methods and instruments.

- CPV & APR/PQR. Continued Process Verification and APR/PQR use traceability data to show consistent performance.

Here, traceability in manufacturing is what lets you answer, “Which API lots and CPP excursions affected these vials, and where did they go?” within minutes.

4) Traceability in medical device manufacturing

For medical device manufacturing, traceability revolves around design and manufacturing records plus UDI:

- DMR and DHR. The Device Master Record (DMR) defines what to make; the Device History Record (DHR) proves how each unit was made.

- UDI traceability. UDI carries device identifiers and production information, enabling recalls, field actions and post-market surveillance.

- Component & lot traceability. Lot-level tracking of high-risk components (e.g. sterilisation batches, electronics, sterile barriers) is essential for targeted field corrections.

- Regulatory context. QMSR, ISO 13485 and EU MDR 2017/745 all embed traceability requirements.

5) Traceability in food processing, sausage & meat processing and produce packing

In food processing, sausage & meat processing manufacturing and produce packing, traceability is tied to HACCP, GFSI schemes and, increasingly, FSMA 204:

- One-up / one-down. At minimum, plants must know which suppliers fed each lot and which customers received it, using one-up / one-down traceability.

- FSMA 204 KDE/CTE. For many foods and produce, FSMA 204 defines Key Data Elements at Critical Tracking Events such as harvest, cooling, initial pack and shipping.

- PTI and case labelling. The Produce Traceability Initiative (PTI) establishes standard case labels linking field, harvest crew and pack line to case and pallet IDs.

- Meat & poultry specifics. For meat, glossaries such as batch-to-bin traceability, GS1-128 raw material intake labeling, catch-weight traceability and FSIS Appendix A lethality compliance describe specific trace links.

- GFSI schemes. BRCGS meat processing controls Issue 9 and SQF Edition 9 emphasise mass balance and documented mock recalls.

Here, traceability in manufacturing is about capturing each hand-off—from field or live animal through cooler, grinder, smoker, slicer, case label and route truck.

6) Traceability in bakery manufacturing and ingredients & dry mixes

Bakery manufacturing and ingredients & dry mixes manufacturing share similar patterns: high throughputs, complex batching and heavy reliance on pre-weigh and staging.

- Flour and bulk scaling. Flour traceability is maintained via Flour Scaling & Silo Weighing and silo changeover records.

- Sponge and preferments. Sponge and Dough Systems and Preferment Scaling provide traceability through fermentation.

- Minor/micro ingredient control. Minor and micro ingredient stations and weigh & dispense automation ensure that small components are traceable and weighed correctly.

- Dry mix genealogy. For dry blends feeding multiple downstream plants, batch material verification, batch-to-bin and lot traceability are critical.

7) Traceability in dietary supplements and consumer products manufacturing

In dietary supplements manufacturing, 21 CFR 111 requires component, label, batch and distribution records that allow full reconstruction of manufacturing and packaging history.

- Component identity & potency. Component lot traceability, potency adjustment factors and batch-specific potency link raw materials to label claims.

- Label control. Labeling control and Supplement Facts labels are part of the genealogy; label version must be tied to each batch.

- Consumer products. In broader consumer products manufacturing, traceability combines lot/serial tracking, RMA/returns, warranty and, sometimes, UDI-like identifiers.

8) Traceability in cosmetics manufacturing

For cosmetics manufacturing, traceability must support both product safety and regulatory documentation:

- CPSR/PIF linkage. Batch records, micro and stability data, and adverse events must tie back to the Cosmetic Product Safety Report and PIF.

- INCI and allergens. Ingredient lots are tracked by INCI names; fragrance allergen disclosure requirements make traceability through fragrance components essential.

- Micro & preservative control. microbial control in cosmetics manufacturing and preservative efficacy challenge testing link back to specific formulas and batches.

9) Traceability in agricultural chemical and plastic & resin manufacturing

In agricultural chemical manufacturing and plastic & resin manufacturing, traceability supports both regulatory compliance and performance claims:

- Chemical management. A Chemical Management System (CMS) tracks raw materials, intermediates, by-products and regulated substances.

- Reactor genealogy. Batch reactor vessel control and PAT tools link process conditions and quality attributes to batches.

- Safety and SDS. GHS Safety Data Sheets are tied to formulations and batches; traceability supports incident investigation and regulatory reporting.

10) Cross-cutting patterns for traceability in manufacturing

Despite very different products and regulations, successful traceability in manufacturing follows a few common design patterns:

- Single lot ID per material reality. One physical lot = one logical lot in systems; no re-use or overloading.

- Scan, don’t type. Use barcode/RFID scanning for movements and consumption; typing is for exceptions and notes.

- Connect MES, LIMS, WMS and QMS. Genealogy spans process execution, lab results, warehouse moves and quality decisions—not just one module.

- Make traceability byproduct of doing work right. Operators follow clear workflows; the system captures trace data in the background instead of adding paperwork.

11) Implementation playbook — strengthening traceability in manufacturing

- Map your material and data flows. For each industry area, map how raw materials, intermediates, finished goods and data move today—across plants, labs and warehouses.

- Stabilise identification. Standardise lot, batch, unit and pallet IDs; adopt GS1, UDI or PTI where appropriate.

- Instrument critical tracking events. Focus first on CTEs: intake, key process steps, test gates, packaging and shipping.

- Integrate core systems. Use APIs or connectors so MES, LIMS, WMS, ERP and QMS reference the same IDs and timebase.

- Practice recalls and “what-if” drills. Regularly test whether you can move from any lot, unit or complaint to a complete upstream/downstream picture within your required time window.

12) How V5 Traceability supports traceability in manufacturing across industries

V5 Traceability by SG Systems Global is built to provide a common traceability spine across all of the industries above:

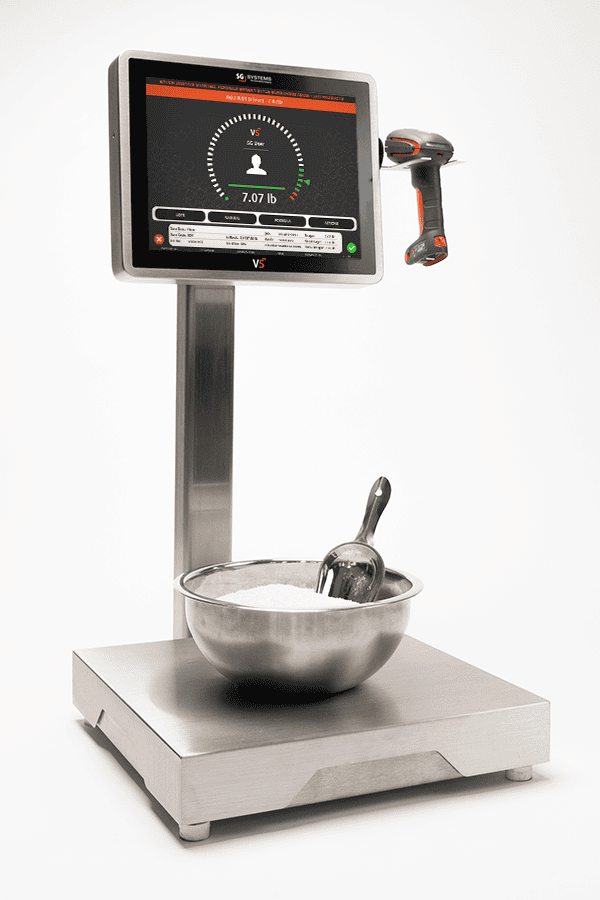

- Execution. V5 MES controls weighing and dispensing, batching, line clearance and in-process checks for pharma, supplements, food, bakery, cosmetics, agricultural chemicals and plastic/resin manufacturing.

- Warehouse & logistics. V5 WMS manages bin/location topology, batch-to-bin traceability, FEFO and outbound shipments across cold stores, dry warehouses and depots.

- Quality & compliance. V5 QMS provides complaint, deviation, CAPA, audit and study management (stability, micro, cleaning, challenge tests) linked directly to batches and lots.

- Integration. The V5 Connect API connects ERP, LIMS, label engines, CPSR/PIF tools and external portals, allowing traceability data to flow end-to-end.

The result is a single, cross-industry approach to traceability in manufacturing, rather than a different home-grown solution for every plant and product line.

13) KPIs that show traceability in manufacturing is under control

- Genealogy completeness: % of shipped volume with full upstream/downstream genealogy (target 100%).

- Mock recall performance: time and accuracy for end-to-end recall drills by product family (pharma, device, food, etc.).

- Mass-balance closure: % of batches where material inputs reconcile with outputs, rework and waste within tolerance.

- Label-version linkage: % of lots where label/artwork version is correctly recorded in the genealogy.

- Audit & inspection findings: number of traceability-related non-conformances per year.

- Untraceable units: count of lots or serials that cannot be fully traced within your recall SLA (target: zero).

14) Common pitfalls in traceability in manufacturing

- Local coding schemes. Each plant or department invents its own lot or serial numbers; cross-plant genealogy becomes impossible.

- Shadow spreadsheets. Critical trace links live in Excel or personal access databases with no audit trail.

- Partial system integration. MES, LIMS and WMS each track different IDs for the same material; reconciliation depends on people rather than systems.

- Untracked rework and returns. Rework loops and RMAs are handled outside the main genealogy model.

- Traceability only tested in a crisis. The first time trace data is pulled end-to-end is during a real recall or regulatory inspection.

15) FAQ — Traceability in Manufacturing

Q1. What is traceability in manufacturing?

Traceability in manufacturing is the ability to follow materials, intermediates and finished goods forwards and backwards through production and the supply chain, with enough detail to support recalls, investigations, regulatory compliance and continuous improvement.

Q2. Why is traceability especially important in regulated industries?

Pharma, medical devices, foods, supplements and cosmetics all have legal expectations for batch records, lot genealogy, product safety and market surveillance. Traceability in manufacturing provides the evidence trail regulators expect and dramatically reduces the cost and risk of recalls.

Q3. Do discrete and process industries handle traceability differently?

Yes and no. Discrete industries emphasise serial numbers, sub-assemblies and DHRs; process industries emphasise batches, lots and continuous flows. But the underlying principles—identification, genealogy and context—are the same.

Q4. How does traceability in manufacturing relate to MES, LIMS, WMS and QMS?

MES captures execution events and material movements; LIMS captures test results; WMS tracks storage and distribution; QMS handles deviations, CAPA and audits. Traceability in manufacturing is the data model that ties all four together around shared identifiers.

Q5. Can small and mid-sized manufacturers achieve robust traceability?

Yes. Many start with focused projects around high-risk products, key customers or constrained resources (e.g. allergen control, DSCSA serialisation, FSMA 204 for selected foods) and scale out once the core patterns are in place.

Q6. How often should we test our traceability system?

At least annually per product family, and more frequently when introducing new plants, partners or systems. Mock recalls, mass-balance checks and “what-if” drills are standard tools.

Q7. Is traceability only about risk and compliance?

No. Once the data exists, it also supports yield analysis, cost-to-serve, supplier performance, OEE, shelf-life optimisation and process improvement. Many companies find the operational benefits outweigh the cost of building the traceability backbone.

Q8. What is the minimum viable approach to traceability in manufacturing?

Controlled identification for lots and key units, scan-based material movements at critical tracking events, basic genealogy linking inputs to outputs, accessible records for recalls, and a plan to integrate MES, LIMS, WMS and QMS over time.

Related Reading

• Foundations: Traceability (End-to-End Lot Genealogy) | Batch Genealogy | One-Up / One-Down Traceability

• Regulations & Standards: 21 CFR 211 | 21 CFR 111 | 21 CFR 117 | ISO 13485 | ISO 22716

• Industry Examples: Pharmaceutical Manufacturing | Medical Device Manufacturing | Sausage & Meat Processing | Bakery Manufacturing | Cosmetics Manufacturing

OUR SOLUTIONS

Three Systems. One Seamless Experience.

Explore how V5 MES, QMS, and WMS work together to digitize production, automate compliance, and track inventory — all without the paperwork.

Manufacturing Execution System (MES)

Control every batch, every step.

Direct every batch, blend, and product with live workflows, spec enforcement, deviation tracking, and batch review—no clipboards needed.

- Faster batch cycles

- Error-proof production

- Full electronic traceability

Quality Management System (QMS)

Enforce quality, not paperwork.

Capture every SOP, check, and audit with real-time compliance, deviation control, CAPA workflows, and digital signatures—no binders needed.

- 100% paperless compliance

- Instant deviation alerts

- Audit-ready, always

Warehouse Management System (WMS)

Inventory you can trust.

Track every bag, batch, and pallet with live inventory, allergen segregation, expiry control, and automated labeling—no spreadsheets.

- Full lot and expiry traceability

- FEFO/FIFO enforced

- Real-time stock accuracy

You're in great company

How can we help you today?

We’re ready when you are.

Choose your path below — whether you're looking for a free trial, a live demo, or a customized setup, our team will guide you through every step.

Let’s get started — fill out the quick form below.