Say Goodbye to COPQ with V5

Eliminate, Prevent, Protect

INTRODUCTION

V5 WMS is built for regulated process manufacturers who need more than stock visibility — they need certainty. From allergen segregation and quarantine control to real-time staging and serialized shipping, V5 WMS enforces inventory rules at the point of use. It’s traceable, automated, and audit-ready — every lot, pallet, and case.

Compliance-ready for FDA, FSMA, GFSI, and ISO standards.

WHAT TO EXPECT

Enforce warehouse control. Ensure perfect shipments. Prove it in every audit.

V5 WMS drives warehouse performance with real-time inventory enforcement, outbound verification, and serialized tracking—purpose-built for regulated manufacturing.

Lot-Level Inventory Traceability

Reduction in Reconciliation

Scan-Verified Order Fulfillment

FASTER LOT RECALL TIME

WMS KEY FEATURES

Materials are zoned (e.g., allergen, cold, quarantine), and barcodes block operators from accessing or moving items from unauthorized locations.

LIVE WIP INVENTORY UPDATES

Inventory updates in real time as items are staged, used, or transferred. Supervisors always know what’s in use and what’s available — no reconciliation delays.

PALLET & CASE SERIALIZATION

Every pallet and case is uniquely serialized and matched to orders. Labels apply automatically for full traceability across customers, carriers, and loads.

LEARN MORE

Precision Inventory for Regulated Operations

In regulated manufacturing, warehouse management isn’t just about storage—it’s about control. That’s why V5’s WMS platform is built to enforce traceability, compliance, and performance at every inventory touchpoint. From receiving to shipping, every movement is validated, logged, and aligned with your operational and quality requirements.

With V5, warehouse actions are no longer siloed or reactive. Whether you’re accepting deliveries, staging materials, picking to order, or managing multi-site transfers, WMS ensures every step is accurate, accountable, and audit-ready.

What You Get with V5 WMS

Receiving with Supplier Lot Control — Validate POs, capture driver info, and scan supplier lots with CoAs and BOLs attached.

QA Hold & Inspection Integration — Automatically flag incoming lots, enforce checklists, and track inspection status.

Location & Allergen-Aware Putaway — Store items based on zoning rules for allergens, temperature, and risk classification.

Full Container & Bulk Handling — Track IBCs, totes, and nested inventory with real-time volume visibility.

Material Issue Enforcement — Stage goods using FEFO, with dual-signature control for regulated or controlled substances.

Cycle Counting with Audit Trail — Blind, scheduled, or triggered counts—with approval workflows and discrepancy logs.

Validated Picking & Palletization — Route pick paths with scan checks, GS1-128 pallet labels, and allergen-safe logic.

Shipping with ASN & EDI — Confirm loads, generate ASNs, and exchange data directly with ERP and partner systems.

Multi-Site Traceability — Control inventory across facilities with full chain-of-custody and compliance enforcement.

Real-Time Dashboards — Monitor inbound status, material availability, cycle count coverage, and outbound readiness.

Explore the Modules Below

Every feature in V5 WMS is designed for high-accuracy, regulated environments—from pharma-grade traceability to food allergen compliance. Click into each module to see how we turn warehouse execution into a controlled, data-driven advantage.

For smaller teams or faster-paced environments, V5 Express offers a lightweight receiving tool that delivers core traceability without slowing you down. Whether you’re stocking bulk raw materials or small batches of ingredients, this module gives you everything needed to log what arrived, where it came from, and where it’s going—with zero fluff and full auditability.

Key Benefits:

Deeper? Let’s get into it!!

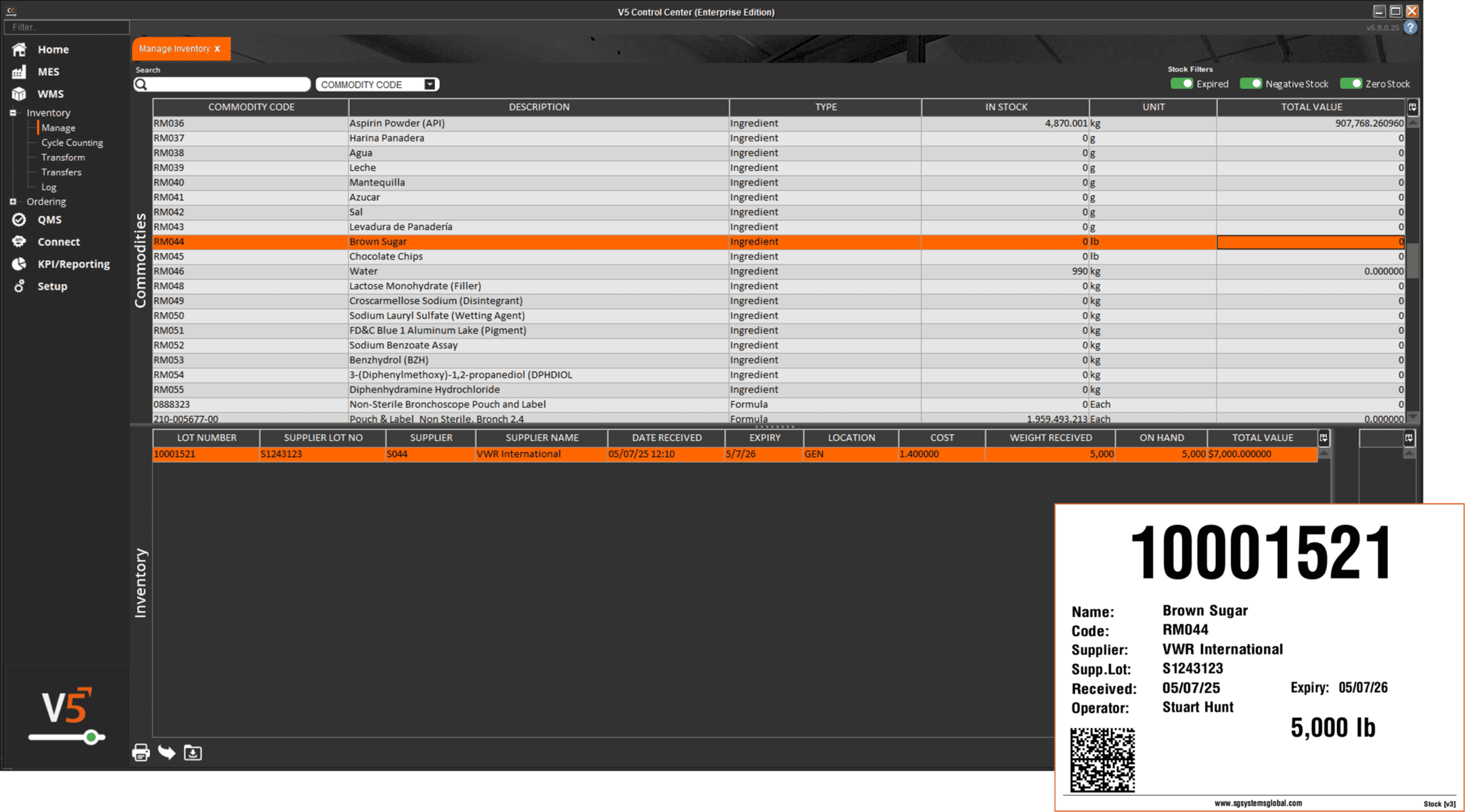

Basic Lot Receiving – Rapid Traceability for Express Users

This screen is designed to handle the essential job of booking in stock—fast. Users select a commodity, enter supplier details, assign the quantity received, and specify a storage location. Supplier lot numbers and expiry dates are recorded in a single view, and a GS1-style label can be generated instantly with all required traceability fields pre-formatted. There’s no QA checklist or deviation handling—just straightforward inventory control for lean operations. Perfect for supplement shops, bakeries, and contract manufacturers who need compliance without complexity.

Start strong—before a single item hits the shelf.

Accurate, compliant, and real-time receiving is the foundation of reliable inventory. With V5 WMS, inbound deliveries are more than just paperwork—they’re tracked events with validation, supplier logging, and audit-ready traceability. Whether it’s one pallet or an entire trailer, V5 ensures every unit is checked, logged, and ready for production or storage the moment it lands.

Key Benefits:

Build confidence into every batch—from the loading dock forward.

With V5, receiving isn’t a bottleneck—it’s a strategic checkpoint. Live dashboards, supplier performance logs, and integrated quality triggers give your team the clarity to act fast, stay compliant, and keep operations moving forward without risk.

Deeper? Let’s get into it!!

???? Receiving – Log Deliveries, Capture Lot Data, Ensure Compliance

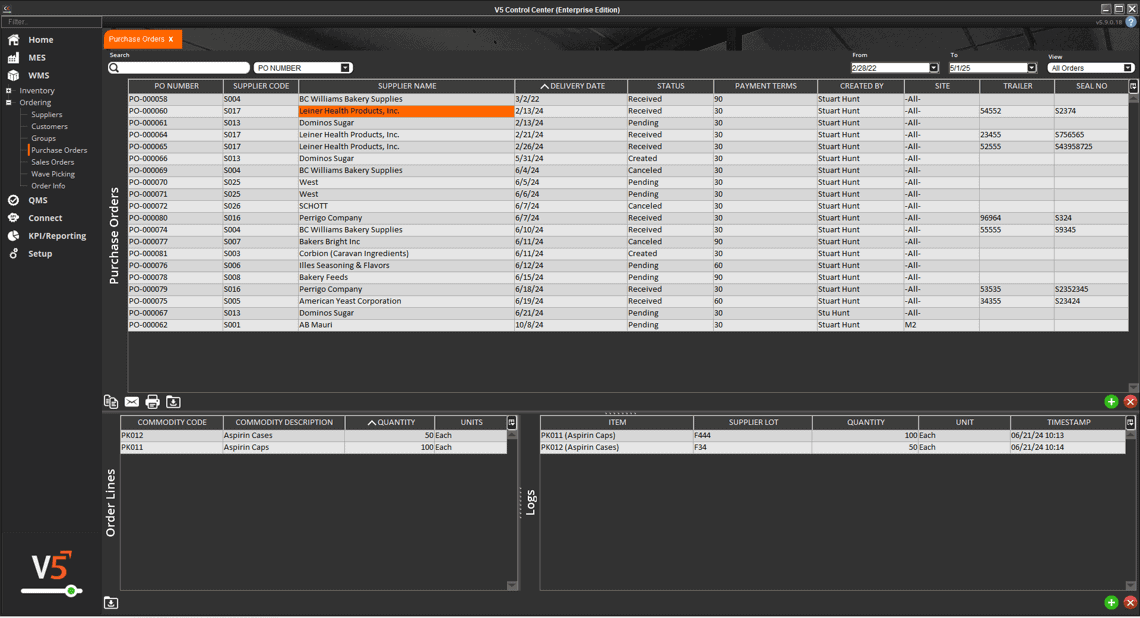

The screen below shows the V5 Control Center’s Receiving module, where warehouse teams manage inbound inventory against purchase orders with full traceability. Whether you’re validating trailer seals, logging supplier lots, or updating PO statuses—everything happens in one unified view.

From here, users can drill into line-level commodities, quantities, and timestamps to ensure every delivery meets expectations. With real-time updates and integrated QMS triggers, V5 makes receiving a proactive control point, not just a transaction.

With tools like seal verification, supplier lot logging, and PO status workflows, V5 ensures your inbound goods are traceable, compliant, and ready for use—no manual steps, no gaps.

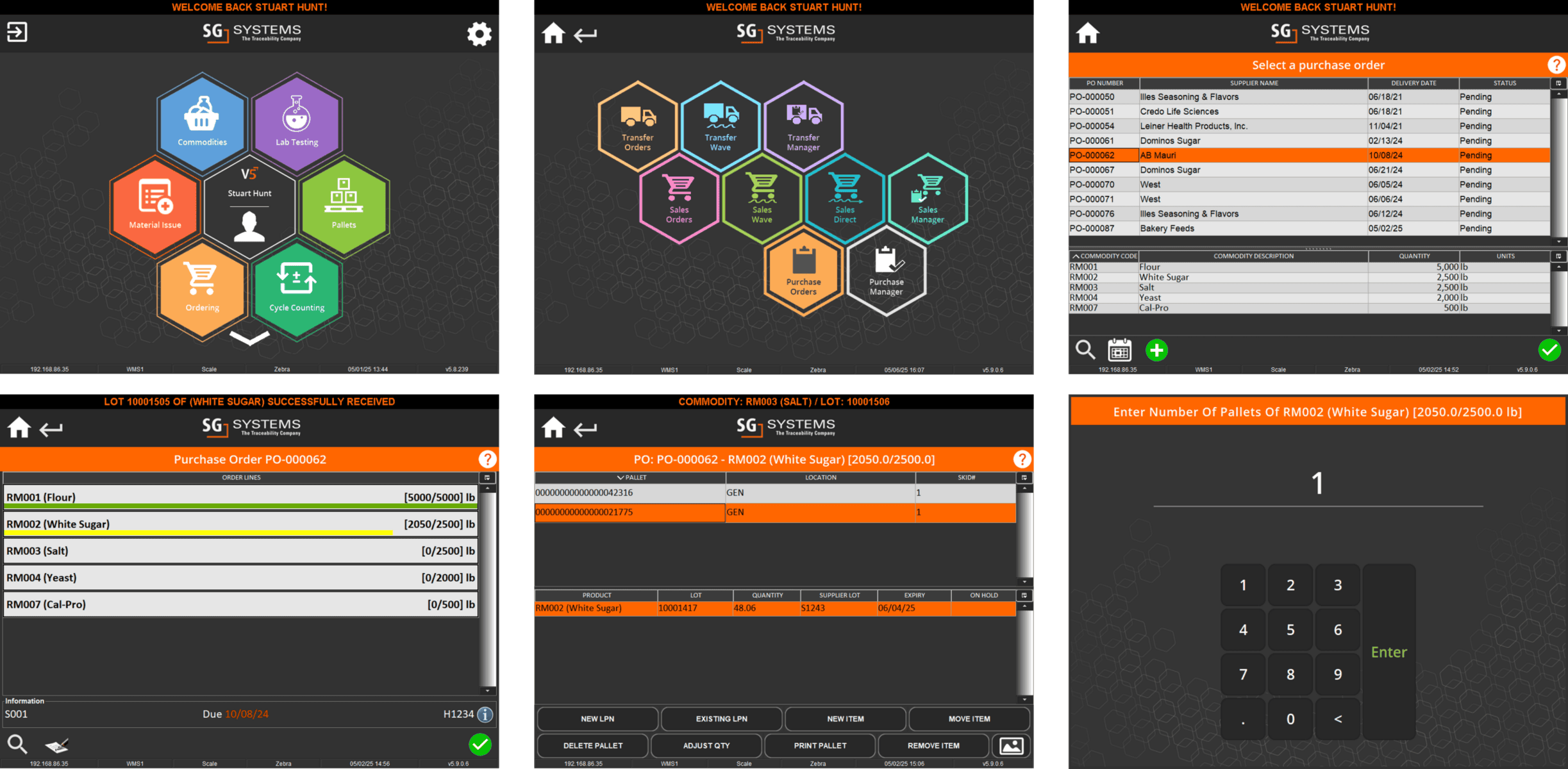

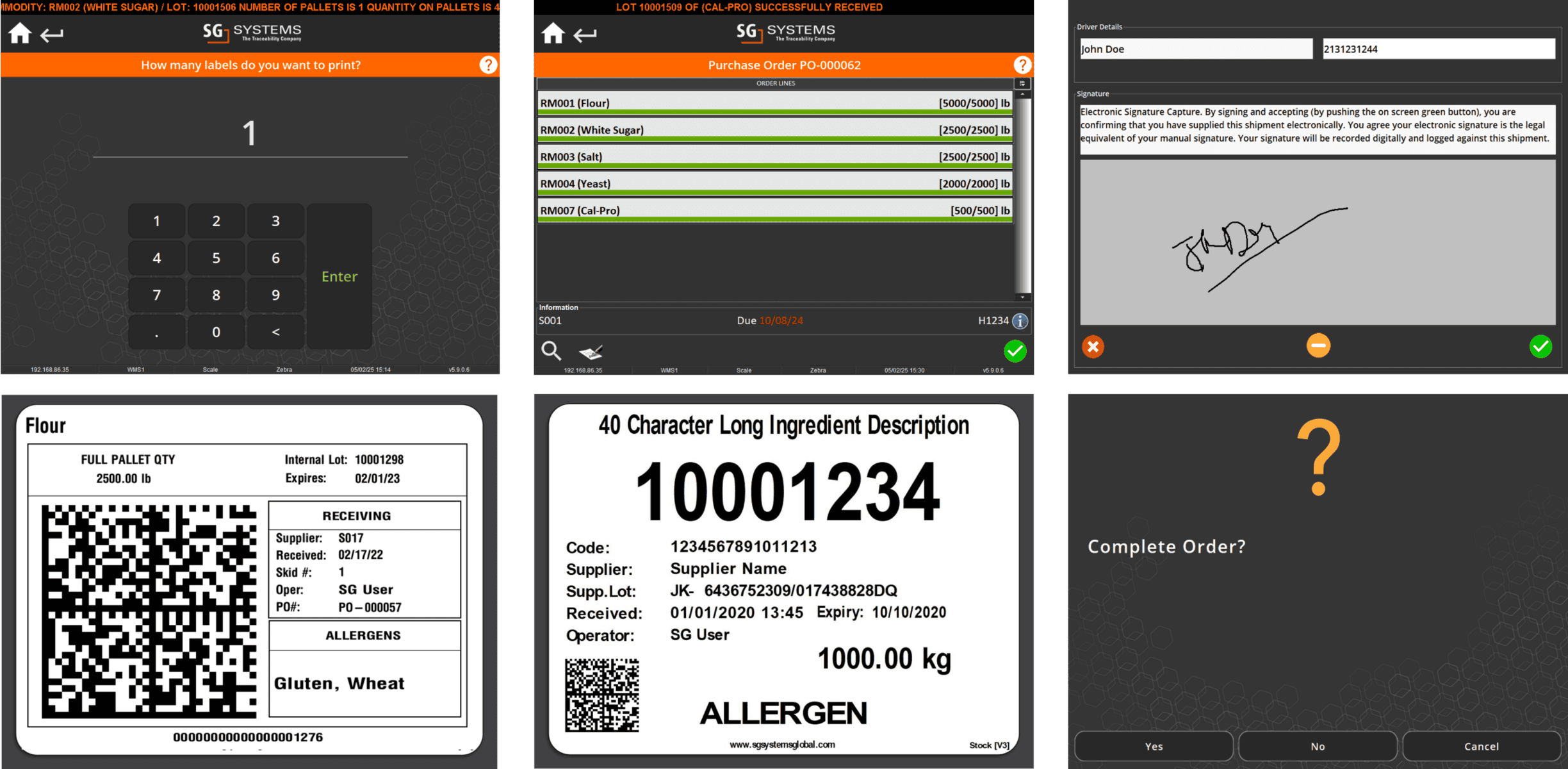

1: PO Selection and Commodity Progress

V5 Receiving starts at the Control Center, where operators select the correct PO from a live list showing supplier, delivery status, and due date. As the PO is opened, each material line displays its received progress in real-time with intuitive progress bars. This gives immediate clarity on what’s left to receive and which items are complete—reducing guesswork, overages, and manual reconciliation. The interface is fast, familiar, and built for precision on the floor.

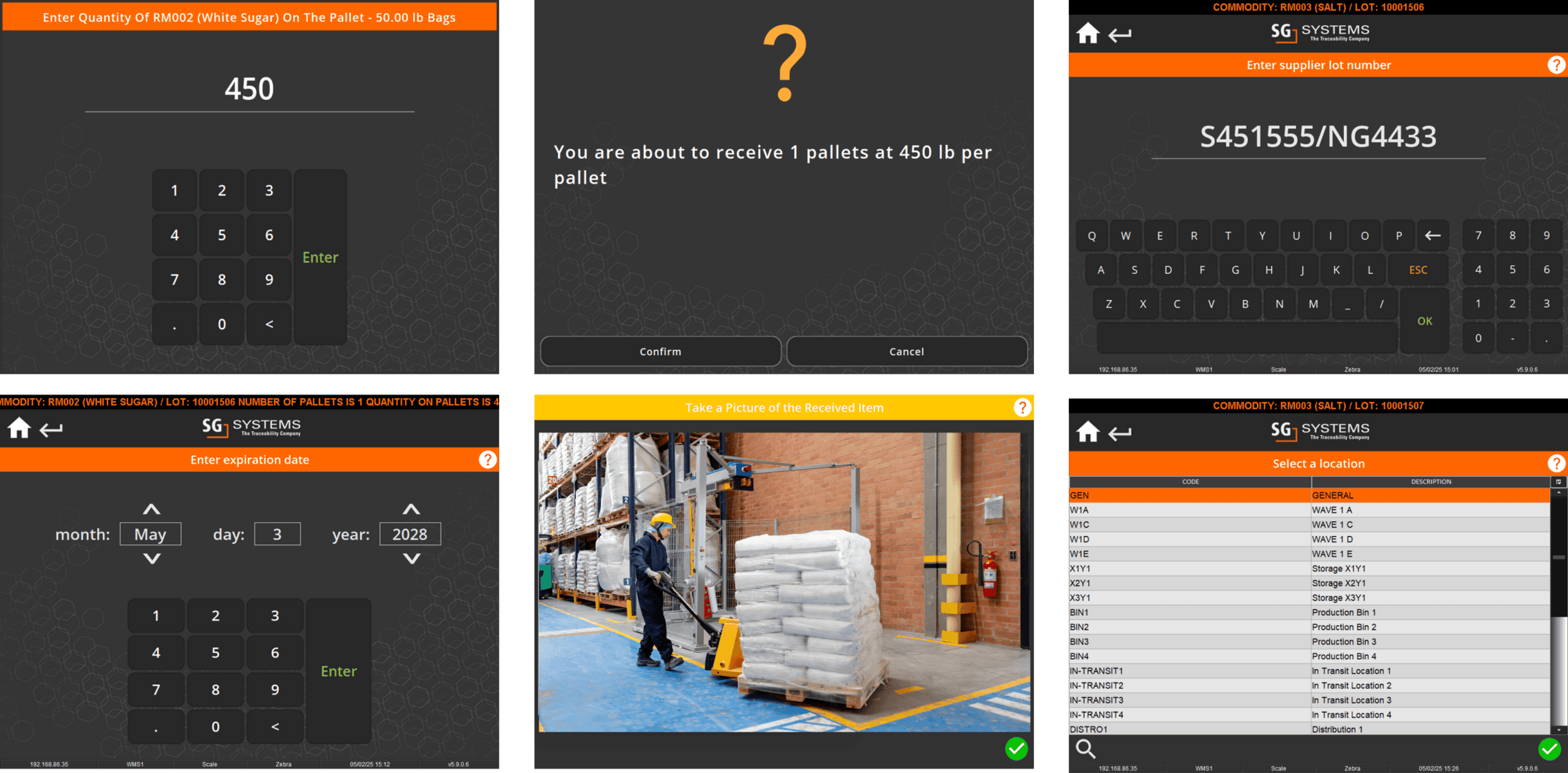

2: Pallet Entry, Lot Control & Location Assignment

Once a material is selected, operators enter pallet counts, quantity per pallet, and assign supplier lot numbers—all from a guided step-by-step flow. V5 then prompts for expiration dates, captures item photos, and allows selection of storage or quarantine locations based on site rules. With each action validated in real time, warehouse staff can receive stock confidently while ensuring every pallet is traceable by location, lot, and label.

3: Labeling, Signature, and Final Confirmation

Final steps in the receiving process capture the driver’s name and signature for full accountability and generate allergen-compliant labels with internal lot numbers, supplier info, expiration dates, and QR or DataMatrix codes. Labels are printed instantly and the PO is finalized with a simple confirmation. These steps ensure full regulatory compliance and provide the documentation backbone for recalls, inspections, and inventory audits—without slowing down the dock.

Quality starts before the pallet hits the floor.

In regulated manufacturing, inbound checks aren’t optional—they’re the frontline of product integrity. V5 makes Quality Assurance an integrated part of receiving, not an afterthought. From trailer seals to lot-level discrepancies, every inbound delivery is validated against your predefined QA checklist. Failed checks instantly trigger deviations, hold statuses, or full-blown CAPAs—ensuring nothing questionable enters production unnoticed.

Key Benefits:

Catch issues early—before they become costly problems.

V5 turns inbound QA from a manual checkbox into a live control point. Whether it’s a seal broken, label mismatch, or missing COA, your team has the tools to detect, act, and document in real time—with full audit trail and accountability built in.

Deeper? Let’s get into it!!

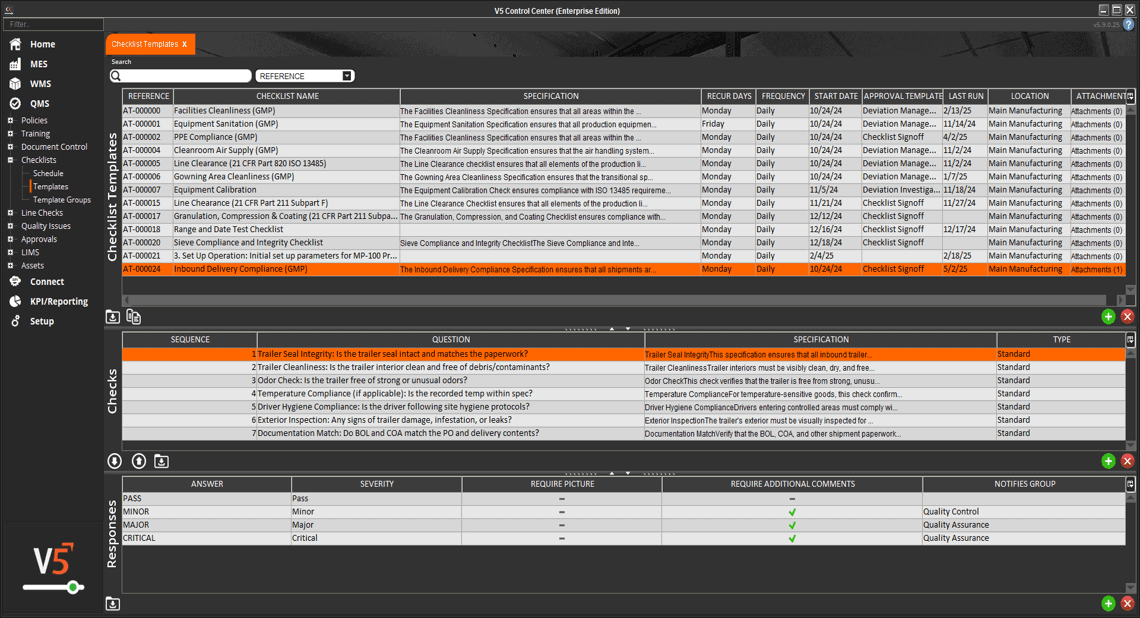

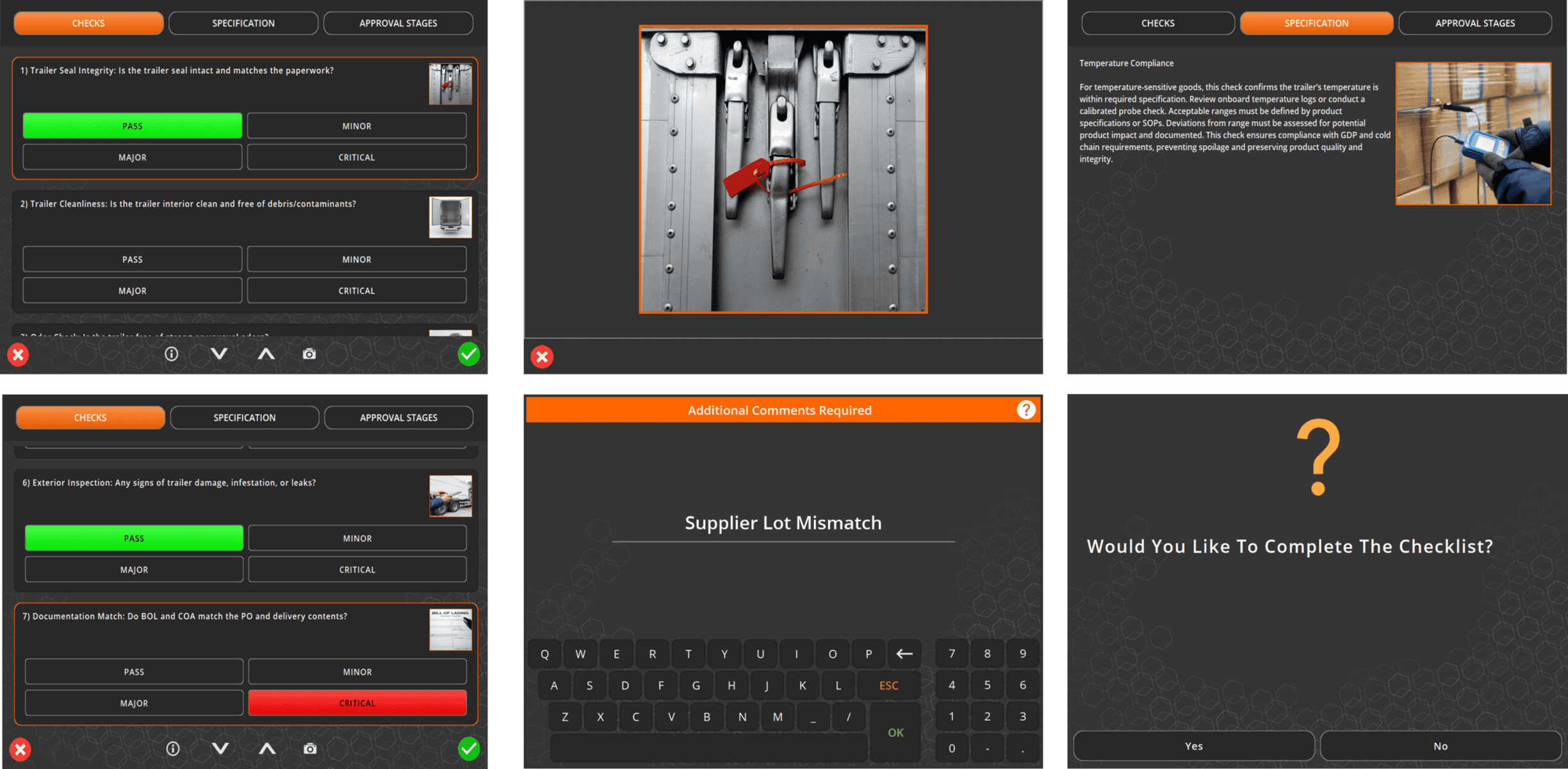

1. Control Center – Define Inbound QA Standards, Automate Triggers

The screen below shows the V5 Control Center’s QA Checklist Templates, where quality teams define every required inbound check—from trailer seal integrity to BOL/COA matching. Each step can be configured with severity levels (Minor, Major, Critical), response logic, required photo evidence, and group-specific notifications. Once deployed, these checklists run automatically at receiving, making every delivery a controlled QA event. Whether it’s GMP, customer requirements, or internal SOPs—V5 ensures nothing gets missed.

2. Terminal – Execute QA Checks with Photos, Comments, and Severity

On the floor, operators complete each QA question using a guided touchscreen interface. With image prompts, severity buttons, and real-time spec guidance, every inspection becomes consistent and documented. If a seal is broken or a COA doesn’t match the PO, the operator can flag it as Critical, enter required comments like “Supplier Lot Mismatch,” and capture supporting photos. These responses instantly push data back to the Control Center for escalation, reducing lag time and risk.

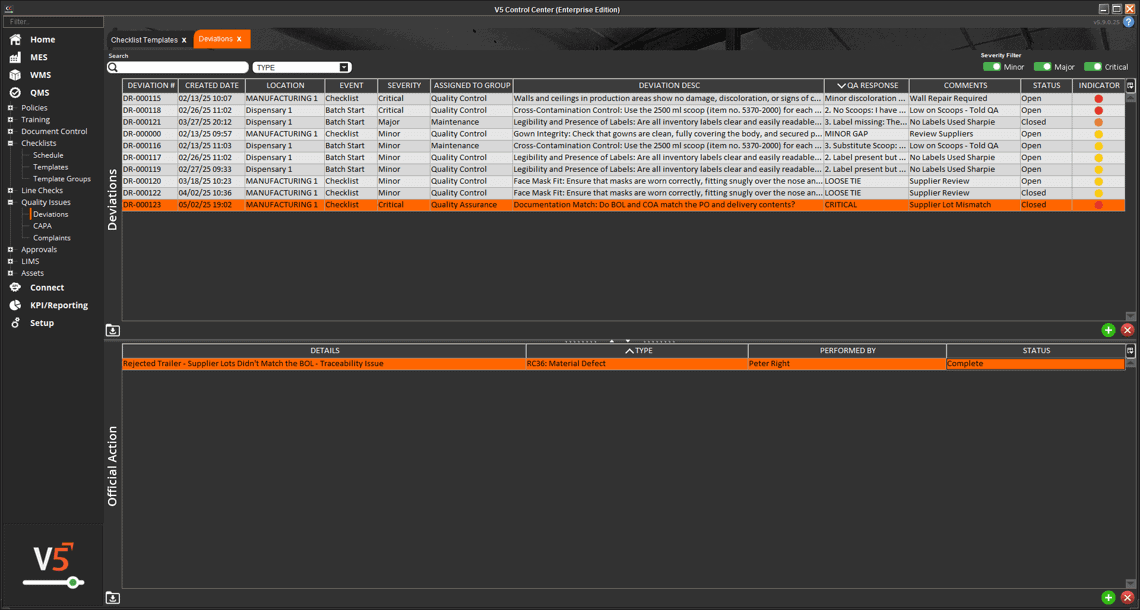

3. Control Center Results – Deviation Logged, Hold Applied, NCR Launched

Back in the Control Center, QA responses feed directly into the Deviations Module, auto-creating issues based on checklist results. In this case, a Critical deviation was logged for a trailer that didn’t match the BOL—marked with a traceability issue and supplier lot mismatch. The material is automatically placed on hold, and an NCR or CAPA process can be initiated. Everything is time-stamped, assigned, and fully visible—closing the loop between floor action and quality oversight.

In V5, location control isn’t just about where things go—it’s about how inventory moves, what it’s allowed to mix with, and when it’s ready to use. From raw material quarantine to cold chain dispatch, every location in the system is fully defined by access rules, weight limits, commodity restrictions, and more. Whether you’re staging product for blending, enforcing allergen segregation, or routing holds to QA bays, V5 ensures stock lands exactly where it belongs—no assumptions, no exceptions.

Key Benefits:

Organized storage isn’t just efficient—it’s compliant.

With V5, your warehouse map becomes a rules engine, ensuring every pallet has a place, and every placement meets spec.

Deeper? Let’s get into it!!

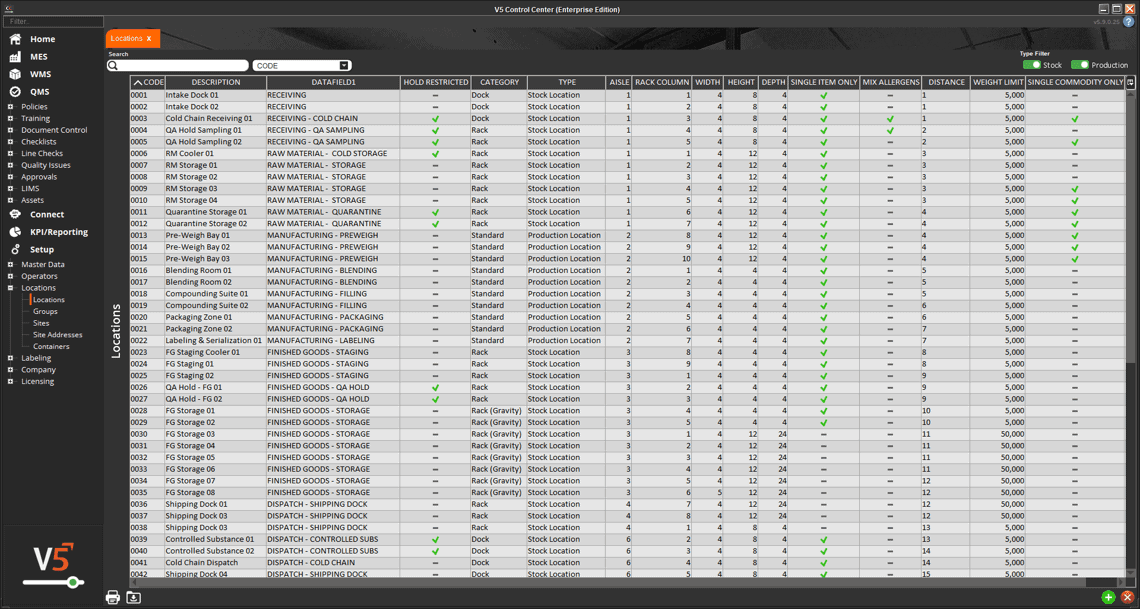

Location Control – Map Every Bay, Enforce Every Rule, Guide Every Move

The screen below shows the V5 Location Master, where each physical space in your facility is digitized with precision. Every rack, room, dock, and cooler is mapped with real dimensions, category types (e.g., storage, quarantine, dispatch), and rules—such as single commodity restrictions, mix allergen controls, or hold-only flags. You can even define physical attributes like width, depth, aisle, and column positions for optimized putaway.

Operators don’t guess where inventory goes—V5 guides them. If it’s a cold chain item, it routes to temperature-controlled zones. If it’s under review, it’s blocked from standard racks and routed to a QA Hold bay. This ensures material integrity, safety, and compliance from receiving to dispatch. Every movement is intentional, every storage decision backed by configuration—not tribal knowledge.

Test with purpose—release with proof.

In regulated industries, lab testing isn’t optional—it’s foundational. V5’s LIMS module seamlessly connects production and quality control by assigning, executing, and recording lab tests directly against raw materials, in-process goods, or finished product batches. From method selection to result entry and deviation capture, everything is digitally linked. No spreadsheets. No silos. Just a clear path from test to traceability.

Key Benefits:

LIMS is no longer a separate system—it’s part of your process.

With V5, lab testing becomes a native step in manufacturing—not an external afterthought. That means faster releases, stronger compliance, and zero gaps between the lab and the line.

Deeper? Let’s get into it!!

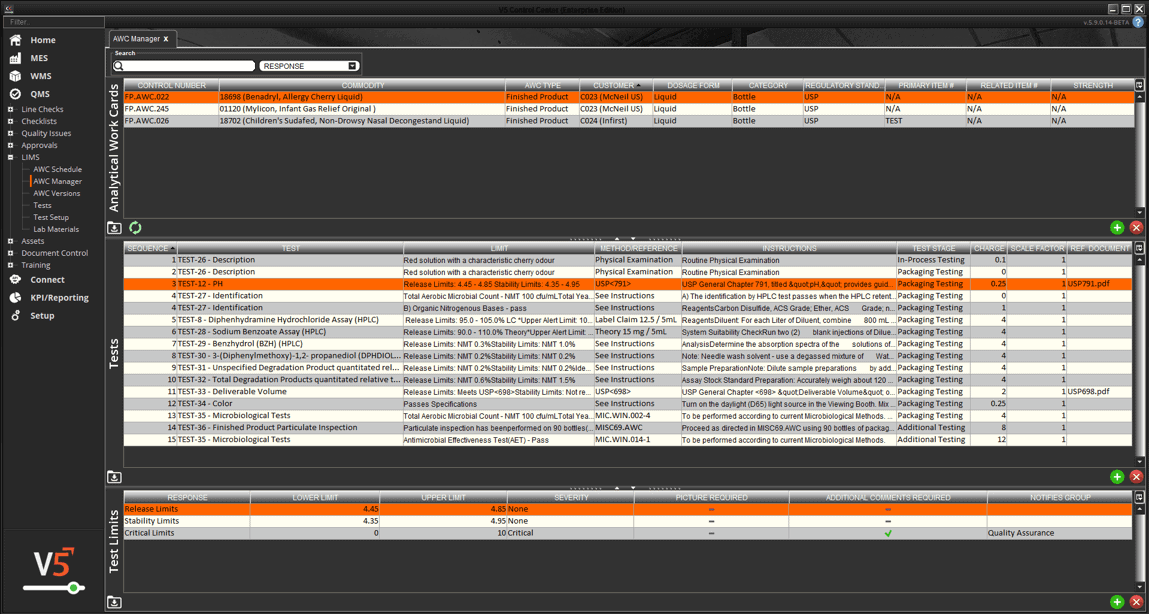

1. LIMS Setup – Define Tests, Methods, and Limits with Control

The Analytical Work Card (AWC) Setup screen is where you configure every test in the system—from assay to particulate inspection. Each test is assigned method references (e.g., USP <791>), charge units, test stages (in-process, packaging, etc.), and most critically, pass/fail criteria including release limits and critical thresholds. Additional options like picture requirements and severity ratings ensure that any nonconformity is flagged and escalated instantly. V5 ensures every test follows a validated protocol—automated, enforceable, and auditable.

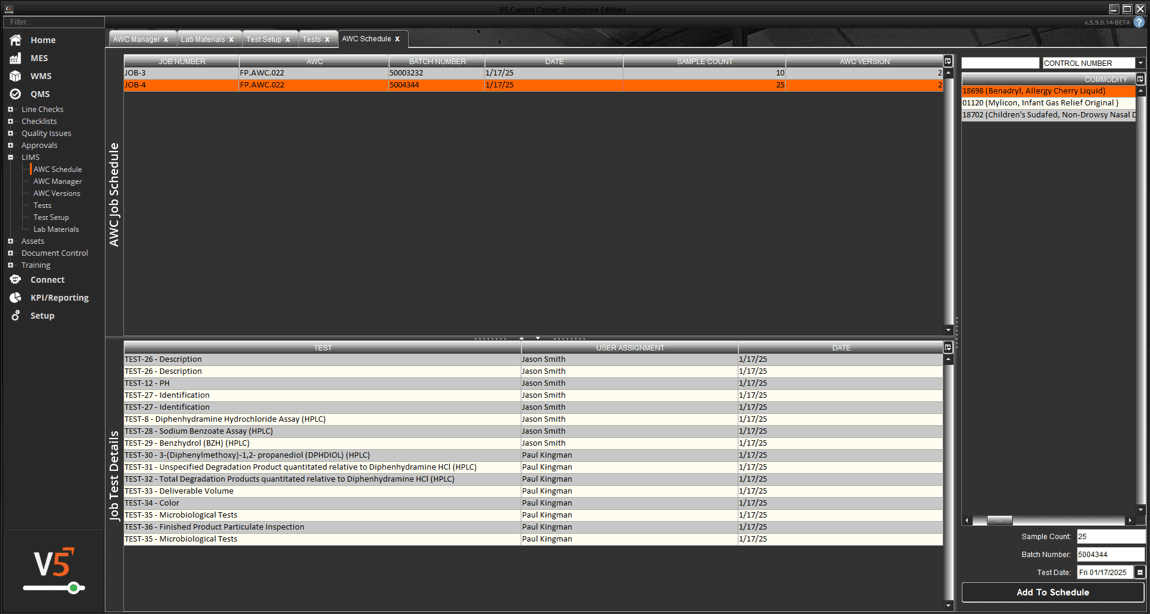

2. LIMS Scheduling – Plan Testing by Batch, User, and Due Date

In the LIMS Schedule view, QA teams assign testing plans to specific batches with detailed job numbers, commodities, and due dates. Each test is linked to a qualified analyst and timestamped to support audit readiness. By centralizing the lab schedule, V5 makes sure no batch slips through the cracks—and that your lab work is both proactive and trackable.

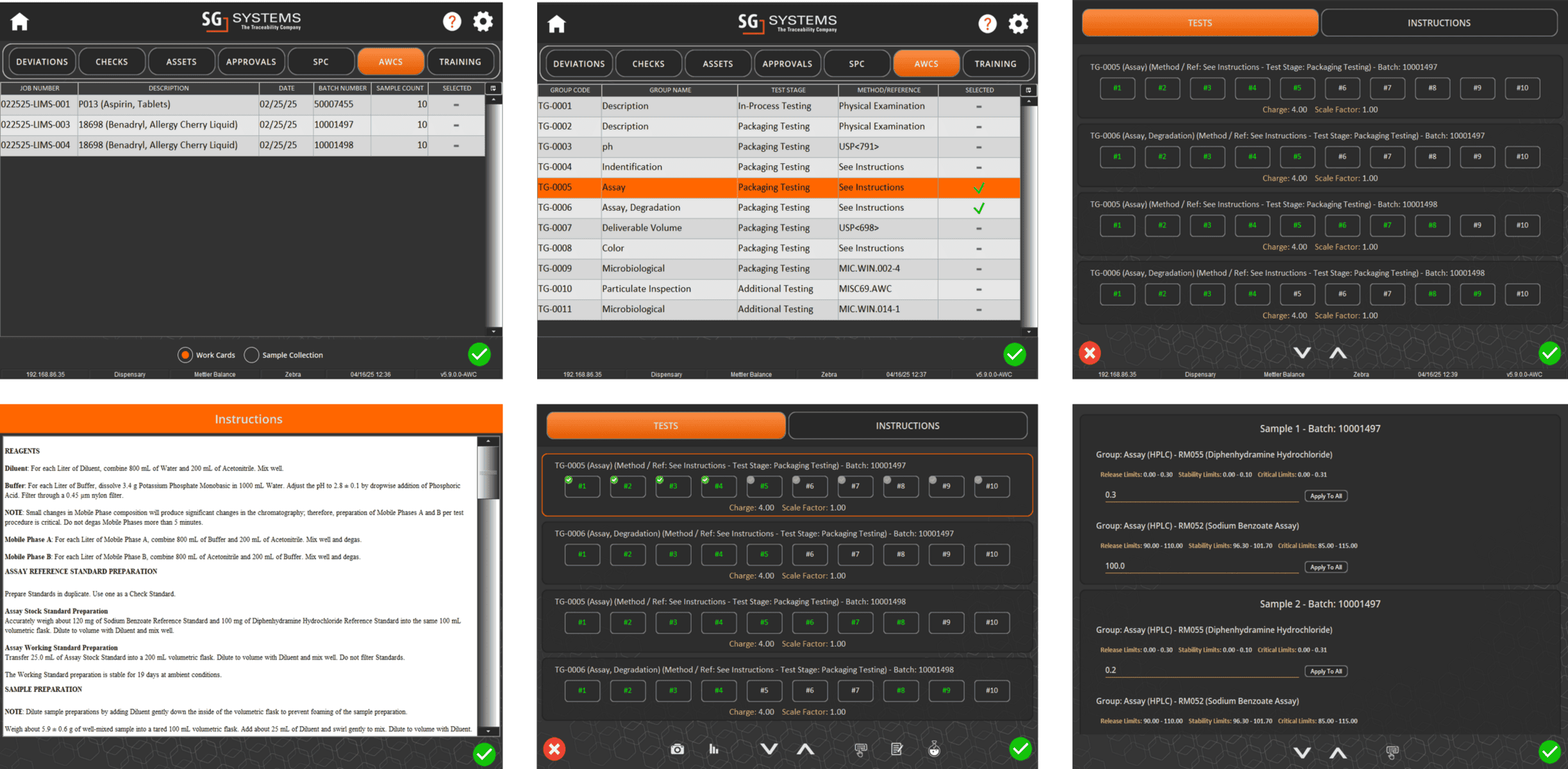

3. LIMS Floor Execution – Perform Tests with Built-In Instructions

From the lab terminal, users select their job and walk through test execution with clear prompts and linked instructions. Whether it’s an HPLC assay or visual inspection, all inputs are validated against preset ranges and documented per batch and sample. If results exceed limits, users are prompted to apply hold status, log a deviation, or escalate for review. The system keeps a complete chain of custody for every result—linked to both the batch and the operator.

In V5, material issue isn’t a guessing game—it’s driven by the production schedule. Whether you’re dispensing actives, weighing excipients, or kitting a complete batch, the system ensures every required material is staged in the right place, at the right time, and in the right quantity. Operators are guided step-by-step to pull inventory by lot, confirm quantities, and push stock into designated staging areas or terminals. No delays. No misallocations. Just precise, traceable material movement.

Key Benefits:

Staging isn’t just logistics—it’s execution readiness.

With V5, your materials are where they need to be before the job even starts—because a batch can only run right if it starts right.

Deeper? Let’s get into it!!

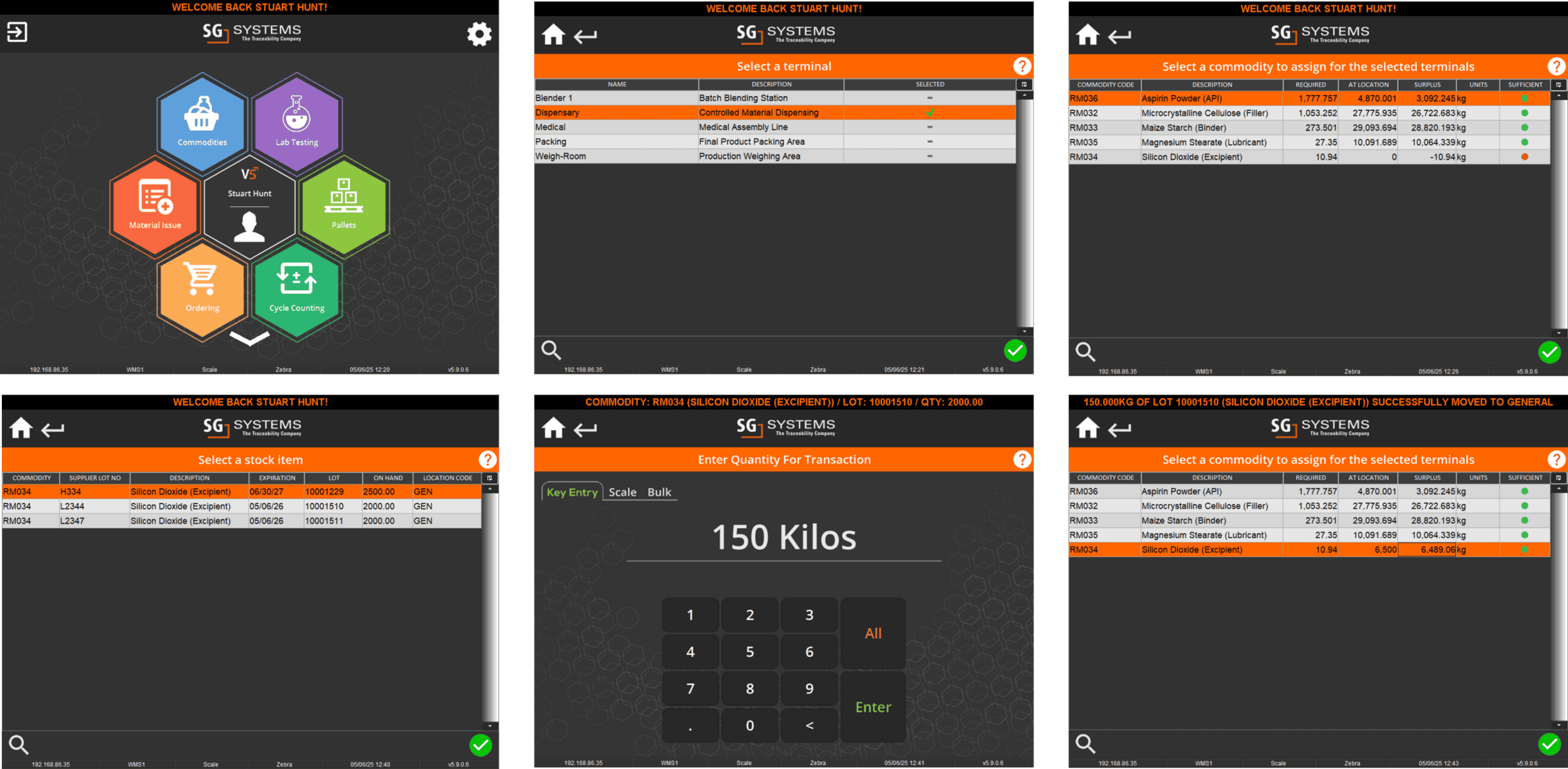

Material Issue – Match Inventory to Schedule, Stage for Success

The screen below shows the V5 Material Issue interface, where operators are guided to stage the exact materials needed for active production jobs. Terminals like dispensaries or blending stations are selected based on job type, and V5 displays real-time requirements per commodity—comparing scheduled demand to current stock levels at staging. Operators then select the correct lot, enter the issued quantity (via keypad or scale), and the system immediately records the transaction against the job. Every movement is precise, validated, and traceable—ensuring production never starts without the right ingredients in place.

No overpicks. No underfills. Just efficient, compliant material flow directly linked to the production plan.

In V5, cycle counting is more than ticking boxes—it’s a strategic safeguard against stock inaccuracies, expired goods, and hidden shrinkage. With intelligent scheduling, blind counts, and deviation logging built-in, the V5 cycle counting module ensures that every item in your warehouse is verified against system records—without disrupting production. Whether you count by commodity, supplier, location, or zone, the platform makes sure you’re focusing on what matters most.

Key Benefits:

Inventory confidence starts with controlled counting.

With V5, your stock checks aren’t just compliance tasks—they’re active tools for driving accuracy, accountability, and financial control.

Deeper? Let’s get into it!!

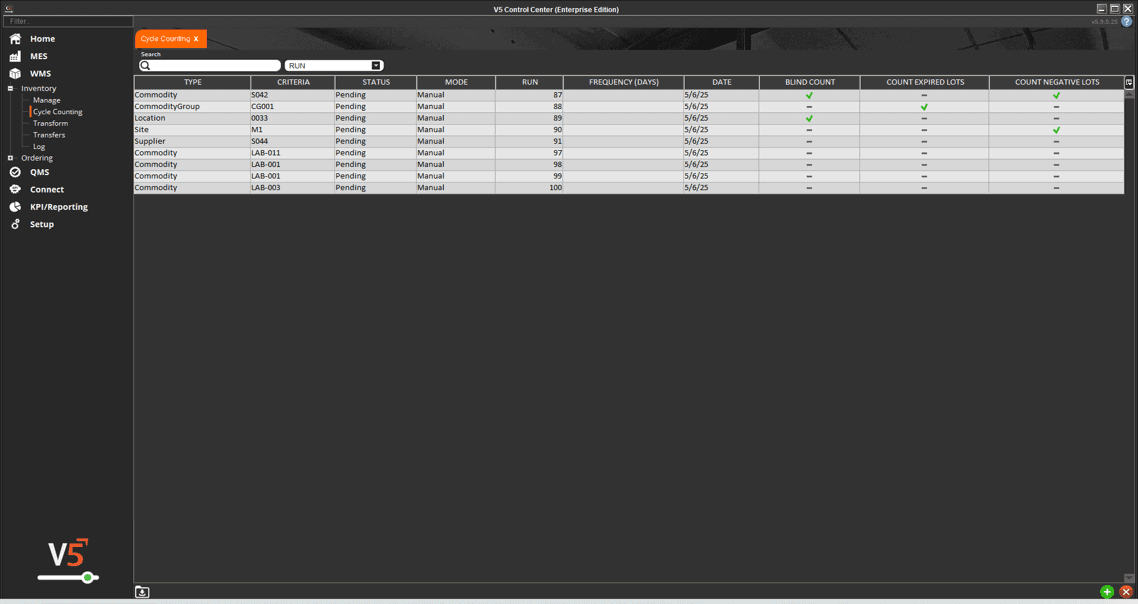

1. Control Center – Configure the Count Plan

The V5 Control Center is where cycle counting strategies are defined and deployed. Users can schedule counts based on a variety of criteria including commodity code, supplier, location, site, or product group, with flexible frequencies and run tracking. Admins can activate blind count enforcement, require expiration date checks, and enable negative inventory reconciliation—making the program adaptable to everything from high-value APIs to bulk raw materials. Every scheduled count includes tracking of who’s assigned, how often it occurs, and which lots or areas it covers.

2. Shop Floor Execution – Count, Justify, Close the Loop

From the warehouse terminal, operators are guided through an intuitive count process. Once they select the assigned count run, V5 presents a lot-by-lot walkthrough, allowing selection of physical stock, quantity input (keypad or scale), and real-time variance detection. If what’s counted doesn’t match what’s expected, the operator must select a predefined reason code—like “expired material,” “damaged bag,” or “accounting error.” This ensures every adjustment is justified, every deviation is documented, and your inventory accuracy is continuously corrected from the ground up.

Order fulfillment is the last stop before your product reaches the customer, and V5 makes sure it’s done right every time. With guided picking, expiry control, and lot-level validation, every sales order is processed with precision. No clipboards, no guesswork—just real-time control over what’s being picked, who picked it, and when it’s ready to ship.

Key Benefits:

Let your warehouse move fast—and stay accurate.

With V5, you don’t just pick stock—you pick with accountability. Every selection is a controlled transaction, tracked from shelf to shipment.

Deeper? Let’s get into it!!

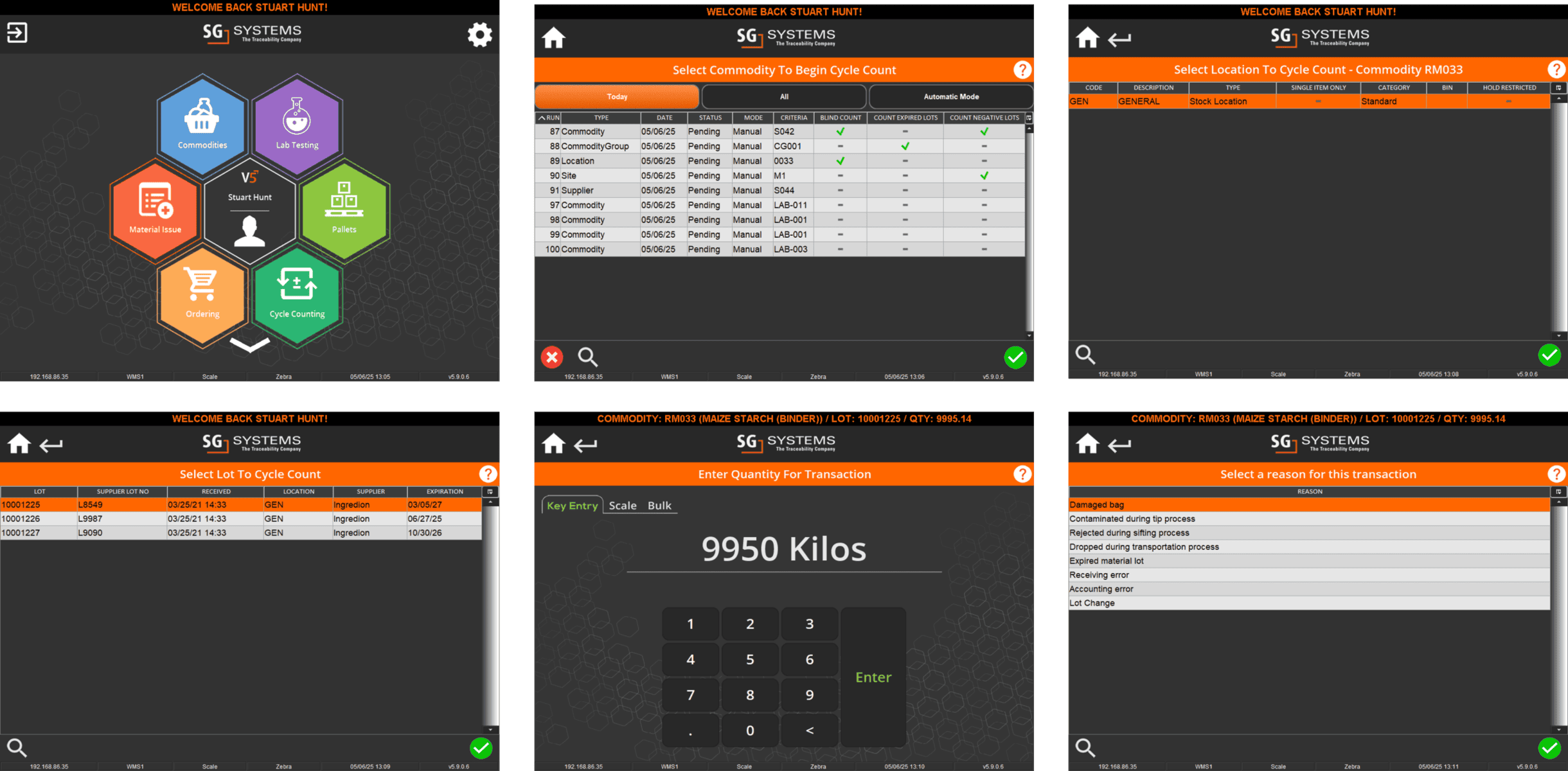

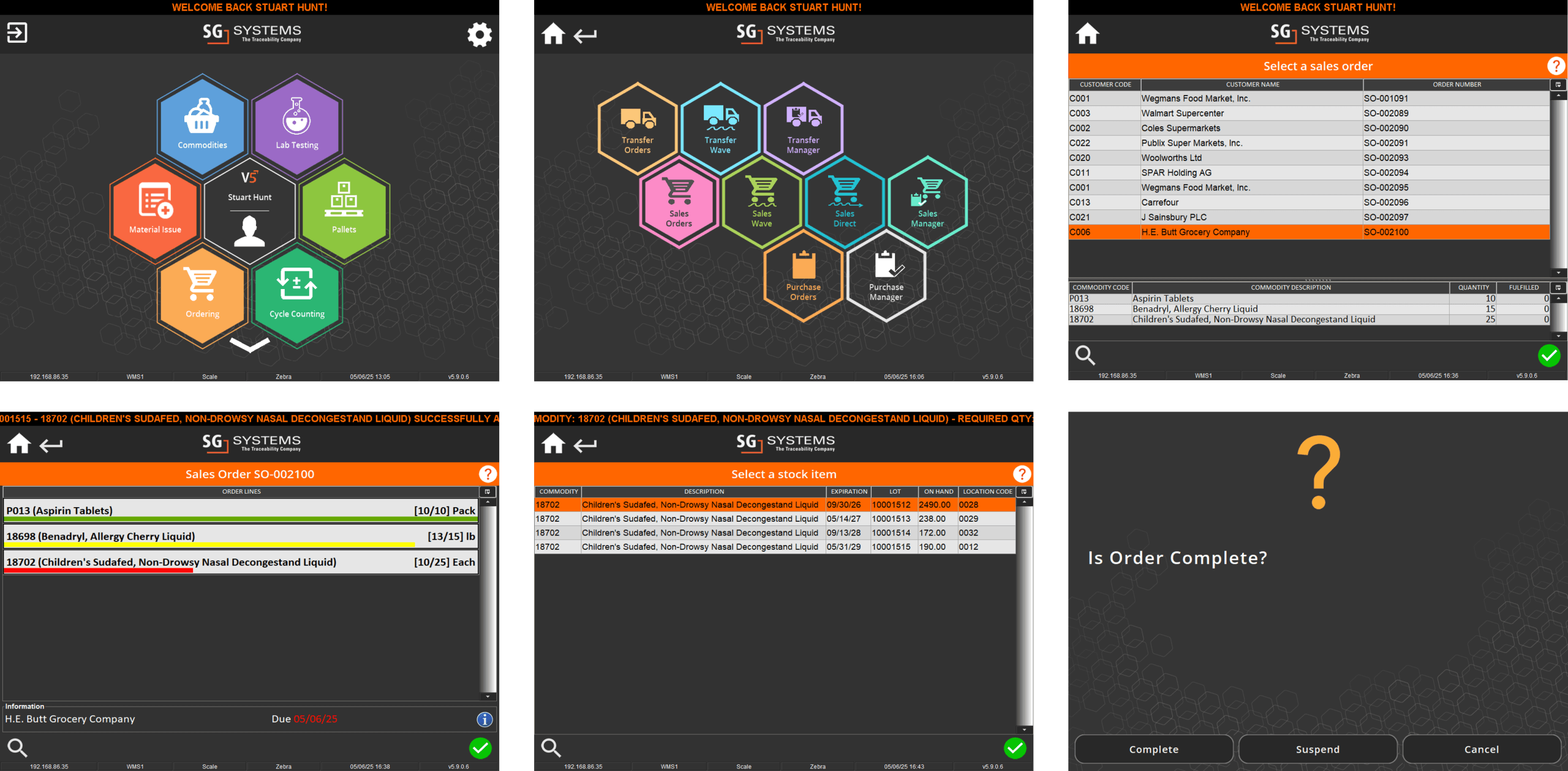

1. Control Center – Sales Order Management

Inside the V5 Control Center, administrators can generate and manage sales orders by customer or destination. Orders are preloaded with line items, quantities, and due dates, allowing warehouse planners to prioritize picks based on shipment urgency. Each line item is tied directly to available lots in inventory, enforcing expiry checks and allergen compliance. Once picking is complete, the control center logs a detailed, timestamped audit of who picked what, when, and from where—giving total shipment traceability.

2. Shop Floor Execution – Guided Picking by Lot

On the warehouse terminal, pickers select their assigned sales order and are guided line by line. Each product displays required vs. fulfilled quantities and presents available lots for selection. The system supports partial picks, prompts for location validation, and highlights any remaining shortages in real time. Once all items are picked and confirmed, users finalize the order with a simple completion screen—seamlessly updating fulfillment logs and preparing the shipment for dispatch.

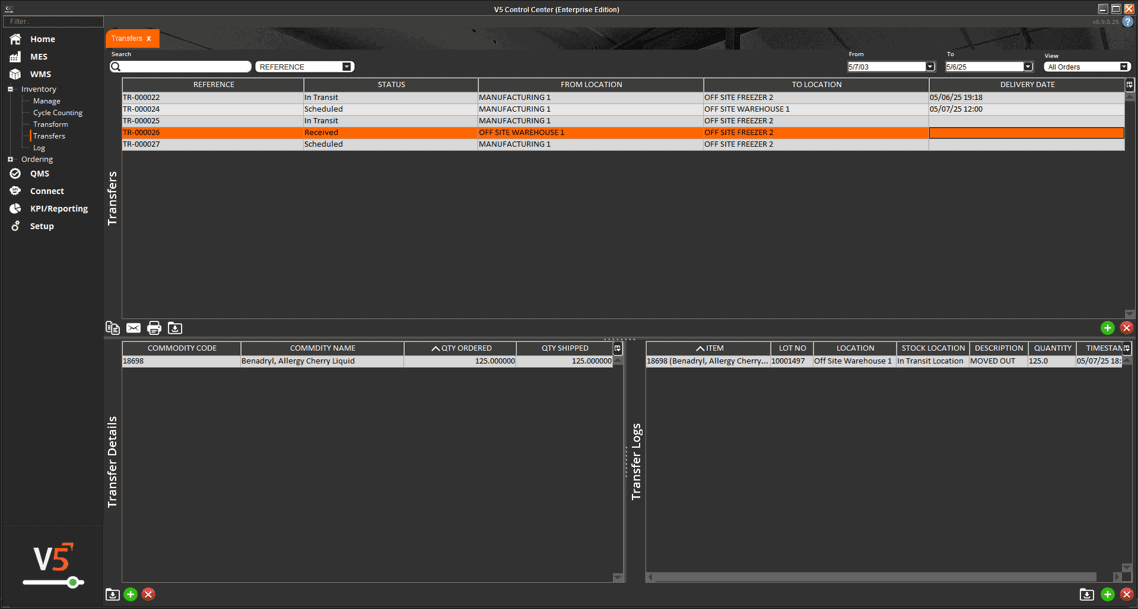

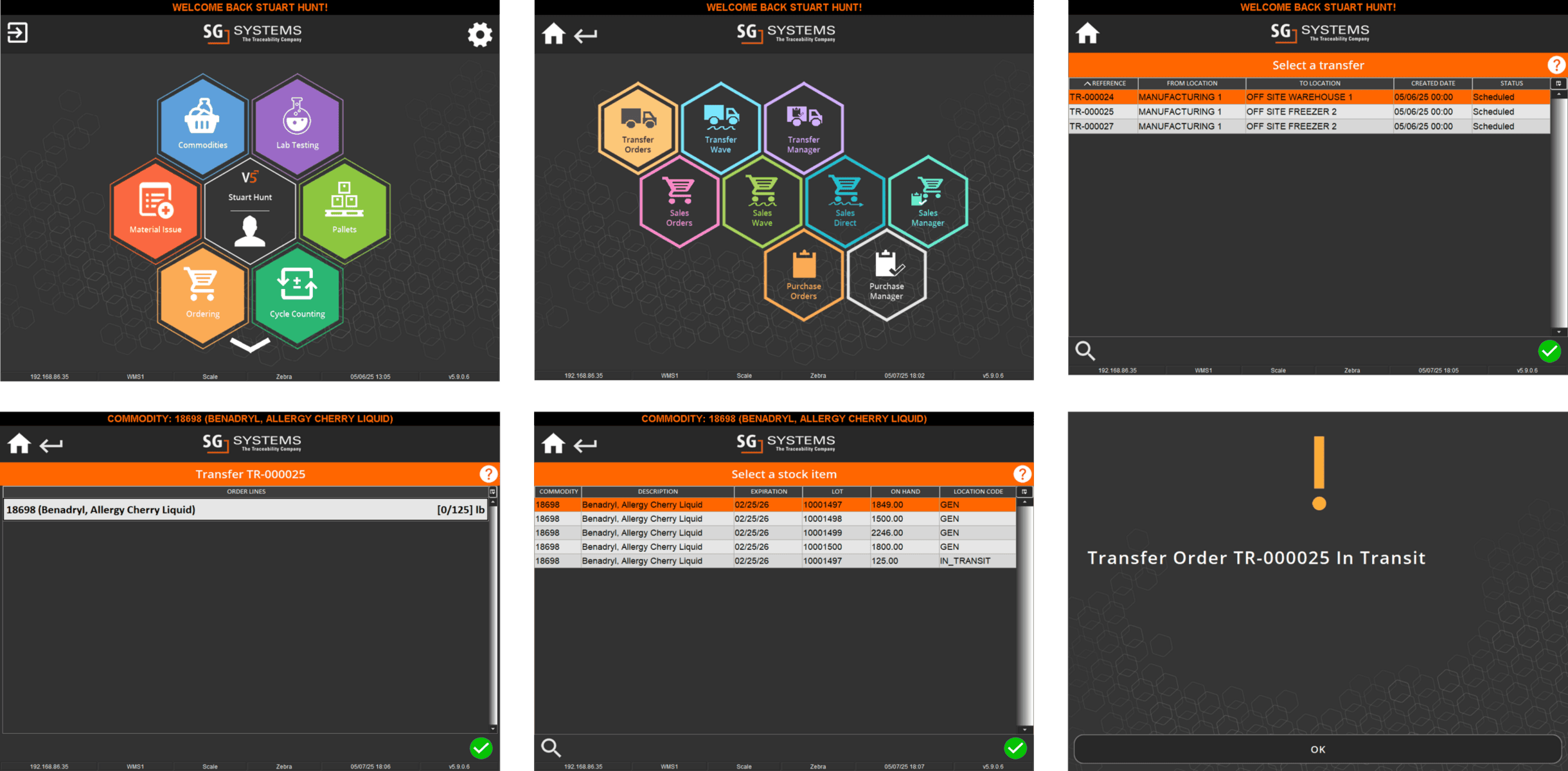

V5’s Multi-Site Transfer Module doesn’t stop at your warehouse doors. When materials are sent to contract manufacturers, external freezers, or 3PL partners, the Control Center ensures full visibility into what left, when, and why. With automatic lot tracking and in-transit monitoring, your team keeps accountability—even when the receiving party isn’t using V5.

Key Benefits:

Dig Deeper:

1.Admin – Internal & 3PL Transfer Scheduling in Control Center

Administrators use the V5 Control Center to schedule transfers between company-owned locations and to third-party partners. When shipping to a 3PL, the process is still tracked identically: scheduled orders are assigned to lots and quantities, marked for the offsite location, and statused through “Scheduled,” “In Transit,” and “Received.” The difference is that for external transfers, V5 captures the outbound record—along with trailer number, seal number, BOL, and driver signature—but marks the final receipt manually once external confirmation (e.g., email or scanned doc) is received.

2. Floor – Pick, Ship, and Digitally Dispatch with Full Traceability

On the warehouse floor, operators use V5 to pick and load items per the scheduled transfer. When the shipment is dispatched—whether to another facility or a 3PL—users confirm the movement, shifting the goods into an “In Transit” location. The process includes on-screen prompts to log driver details, take photos, and record seal integrity. Once confirmation of arrival is received through external means, the admin marks the order as “Received” in V5, preserving the full chain of custody without requiring the 3PL to interact with the system.

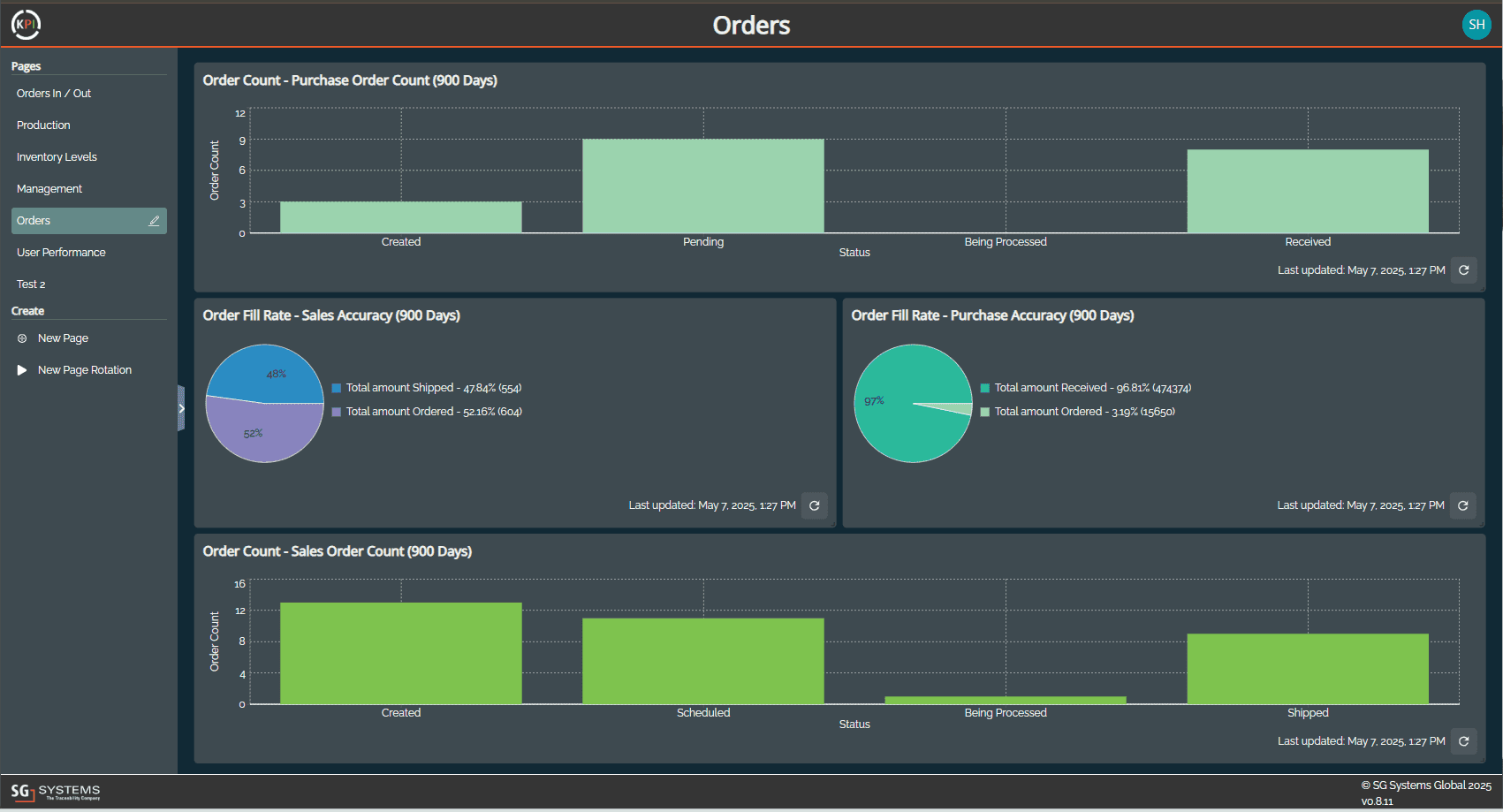

Visibility is power. The V5 KPI Dashboard puts real-time warehouse metrics front and center, giving teams the insight they need to stay on target. Whether you’re tracking order fulfillment rates, inbound accuracy, inventory trends, or site-specific alerts, the KPI suite brings data-driven accountability to your warehouse floor. From operators to executives, everyone sees the same truth—live.

Key Benefits:

Dig Deeper:

The KPI suite is entirely user-configurable, enabling management to define their own metrics, choose display types (bar, pie, line, etc.), and set update frequencies down to the minute. Each widget can pull from live inventory, order, or operator data, and dashboards can rotate across displays in the warehouse or be restricted by user role. Real-time insights replace lagging reports—driving faster decisions and sharper accountability across every shift.

Tier Indicator

▮▯▯ Express ▮▮▯ Professional ▮▮▮ Enterprise

See Pricing for Tier Details

OUR SOLUTIONS

GET IN TOUCH

Let us show you what compliance without complexity looks like. Whether you're in pharma, food, or supplements—we'll tailor the demo to your industry.

Got a batch record or MMR? Send it over. We'll set it up in V5 so you can see exactly how it works—your process, in our system.

This isn’t just a demo. It’s a hands-on trial built around your workflow. Let’s make your next audit effortless.

WHAT'S NEW

Eliminate, Prevent, Protect

From Pallet to POS—recall ready

Where ERP ends, V5 begins.