Bulk Ingredient Management Software

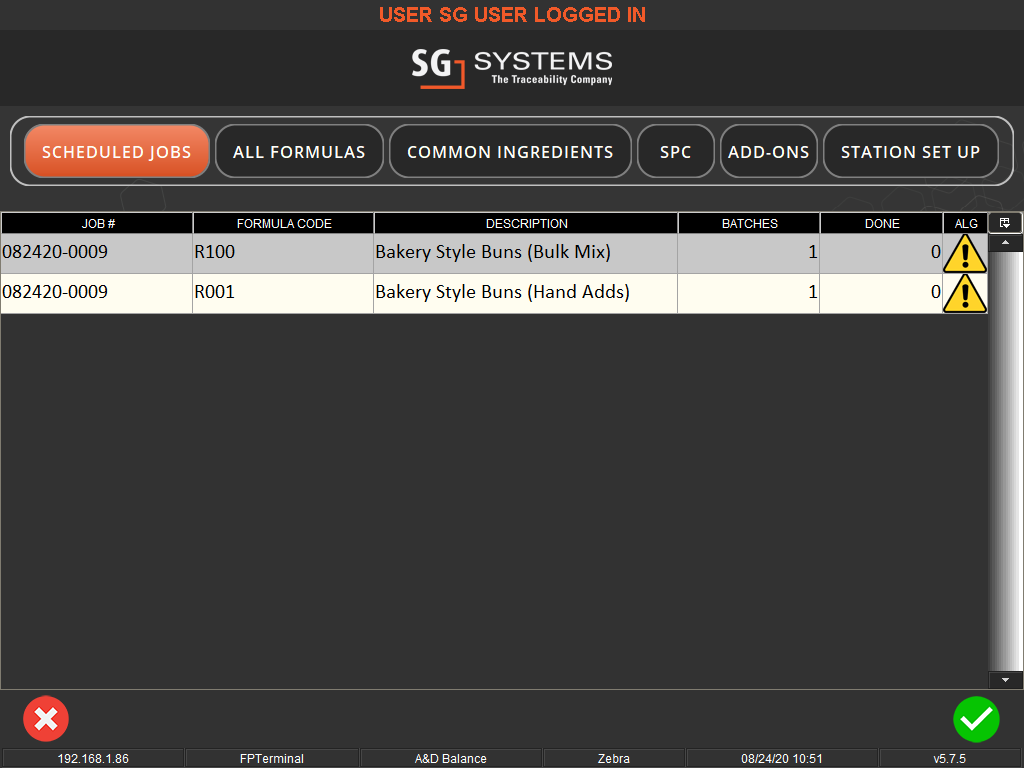

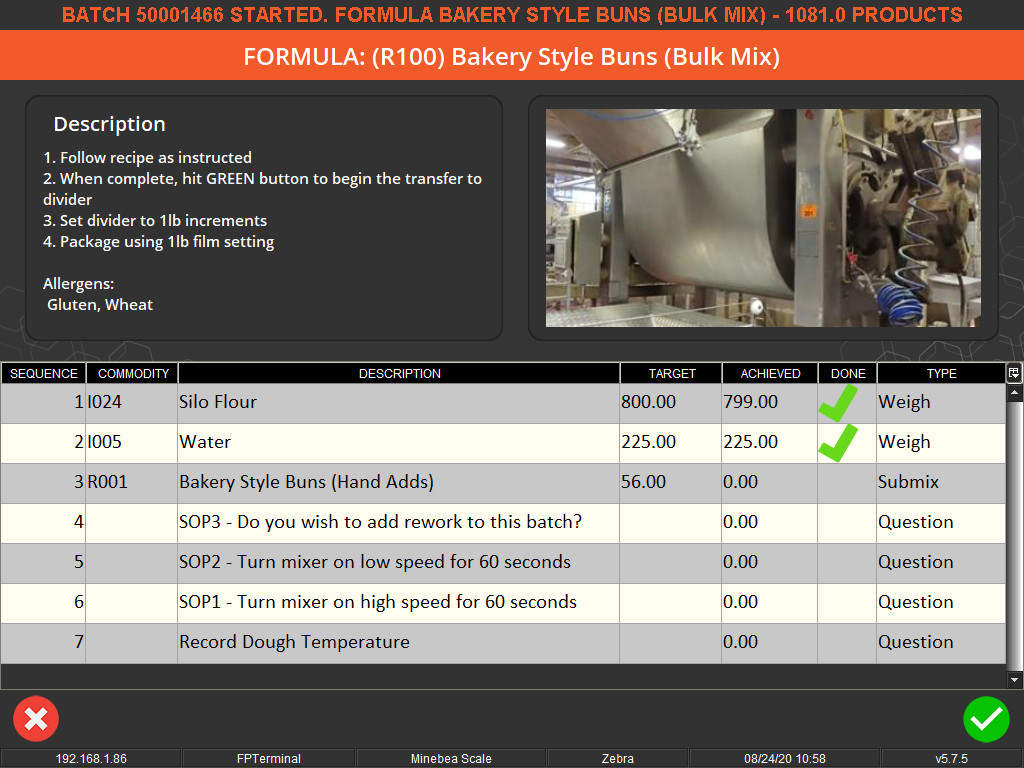

Ingredient Management Software, exemplified by systems like the V5 Bulk Ingredient Control System, plays a pivotal role in modern manufacturing processes, particularly in industries dealing with high volumes of bulk-fed dry or liquid ingredients. These systems ensure that ingredients are accounted for and tracked accurately, whether in mixed or separated lots. This accuracy is crucial in preventing costly recall situations and maintaining the integrity of the production process.

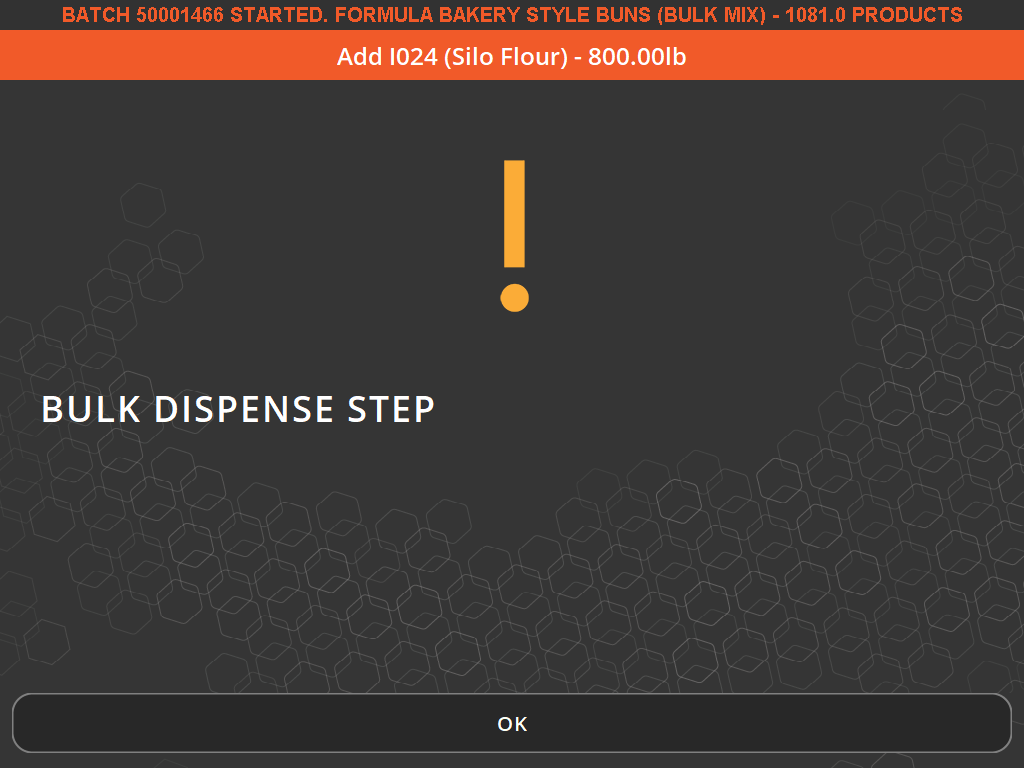

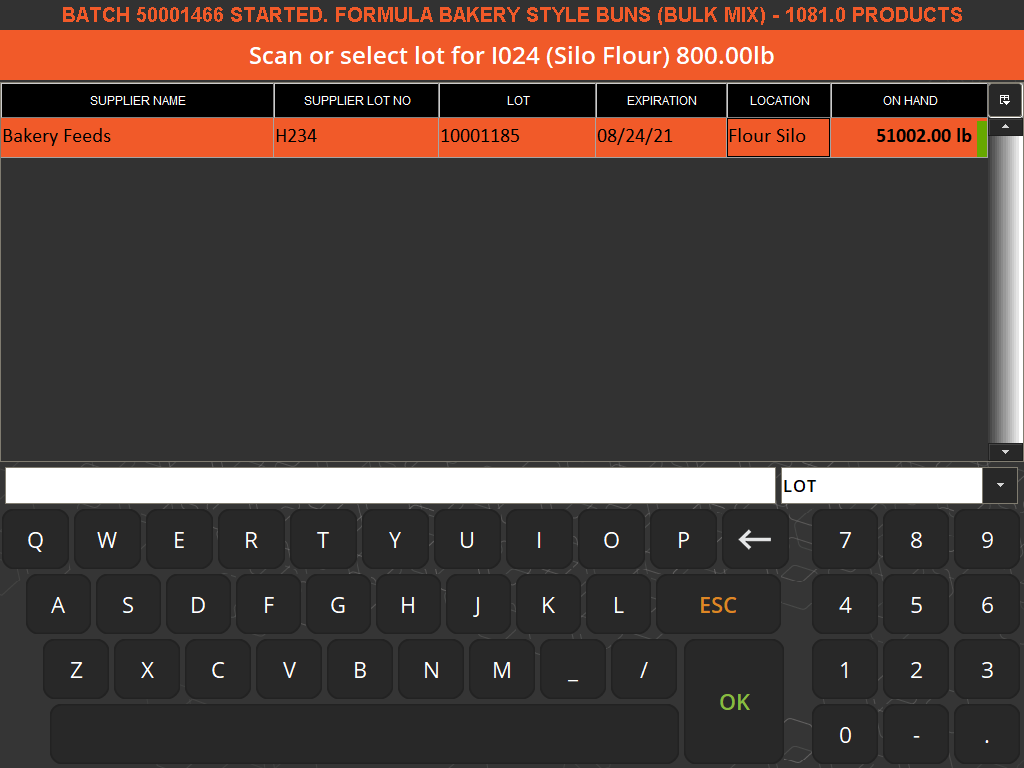

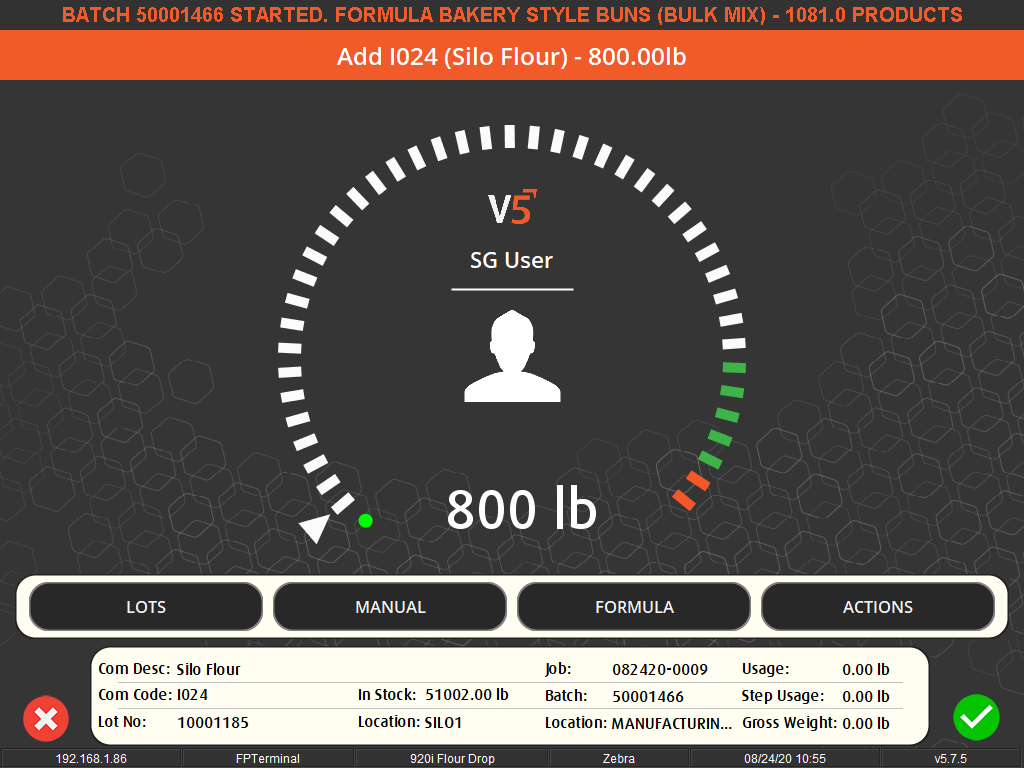

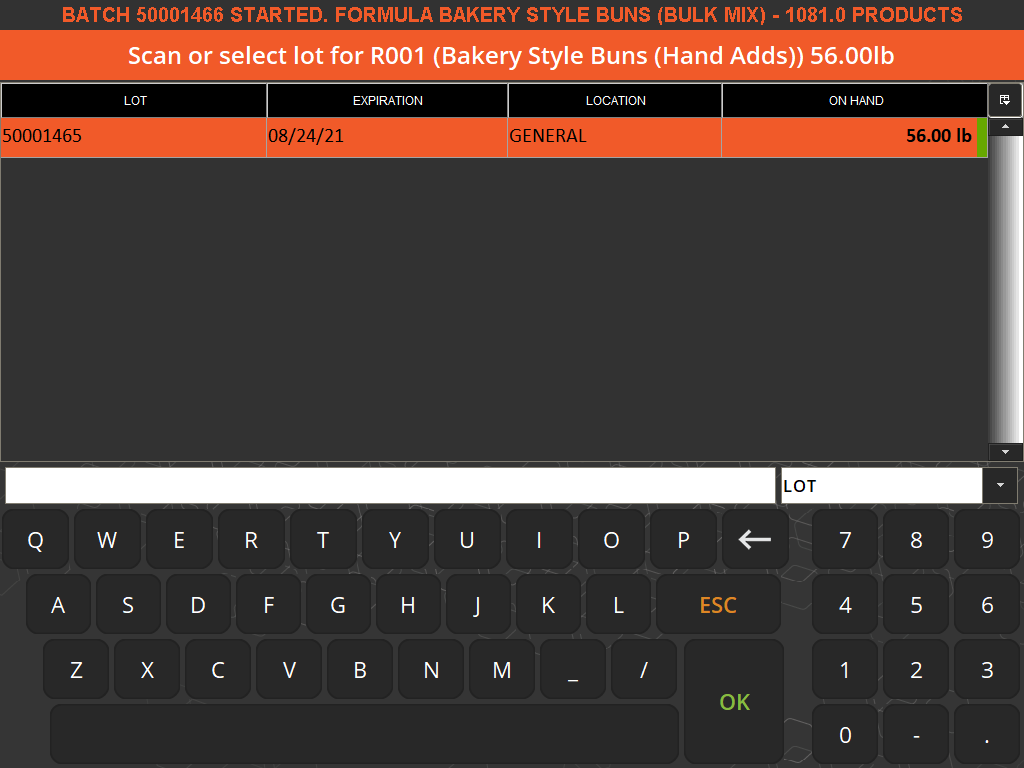

One of the key features of such systems is their ability to manage the traceability of automatic bulk ingredient movements, such as transfers from silos to mixers. This capability is essential in ensuring that the right ingredients are used in the right quantities, thereby maintaining product quality and consistency. The integration with Programmable Logic Controller (PLC) systems further enhances this, allowing for seamless communication and transfer of ingredients while eliminating the need for paper records.

The flexibility of Ingredient Management Software is also a significant advantage. These systems can be configured in numerous ways to suit various applications, including in food and beverage, bakery, chemical, plastics, pharmaceutical, and life sciences sectors. This adaptability makes them a valuable asset across a wide range of manufacturing environments.

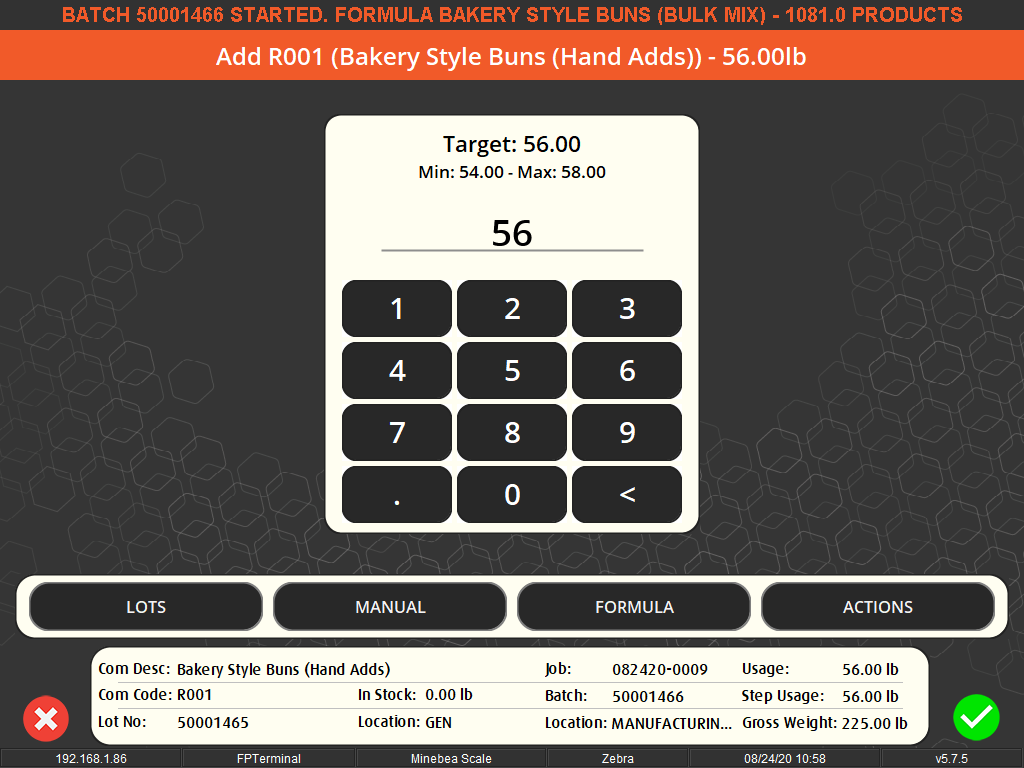

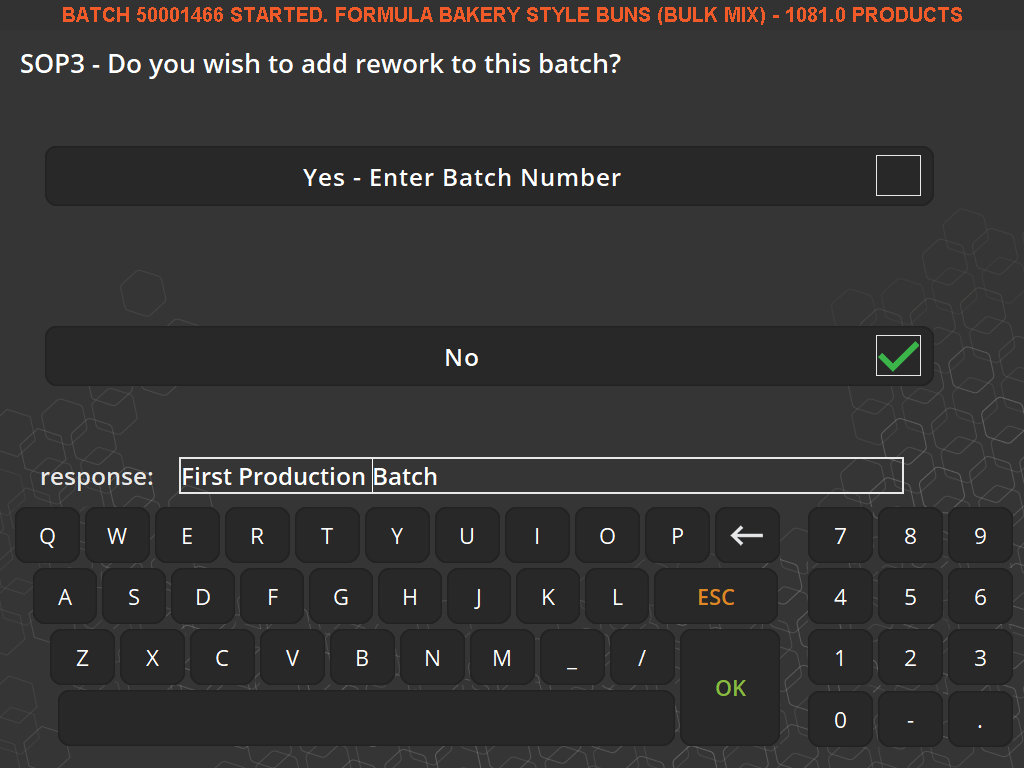

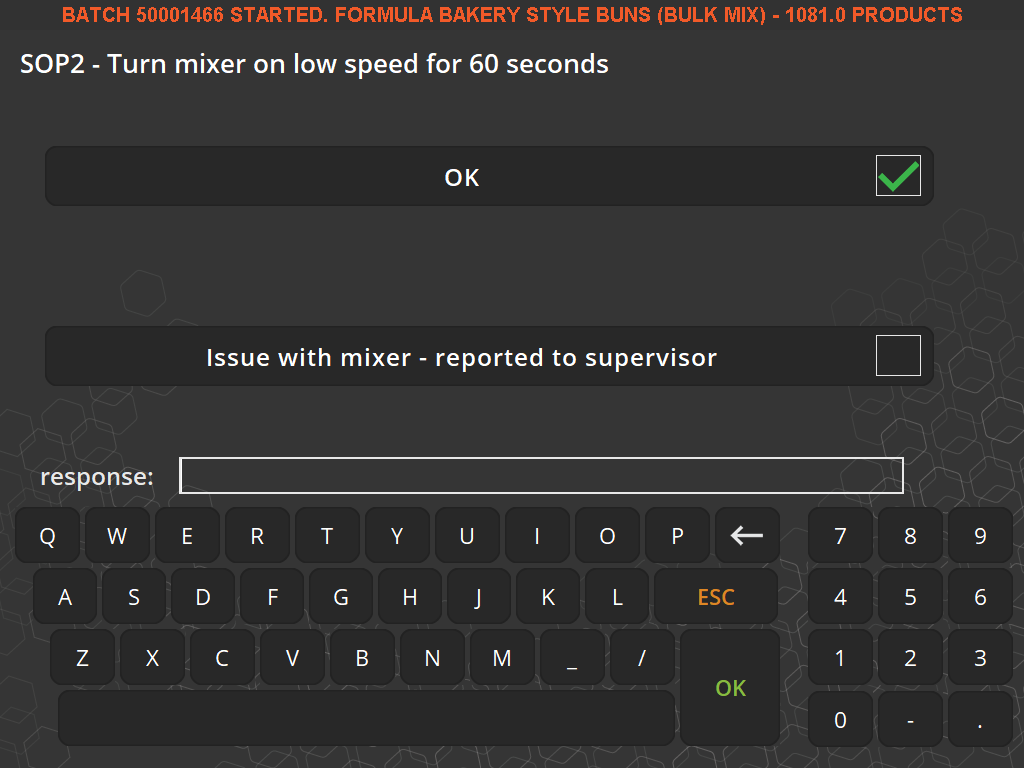

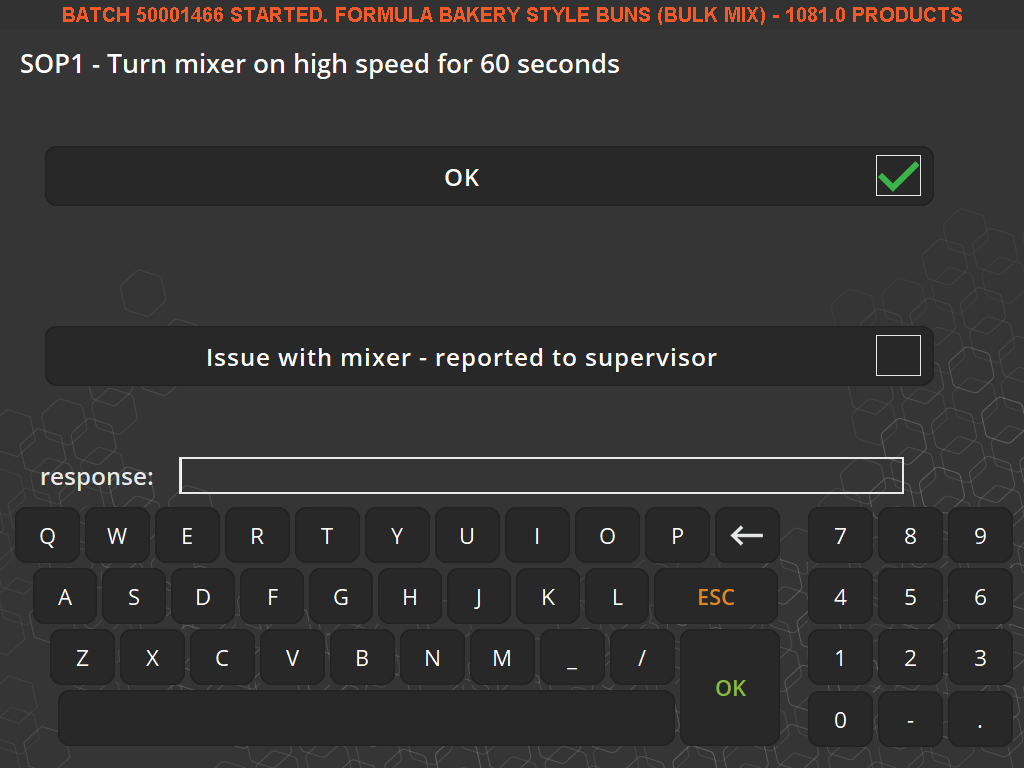

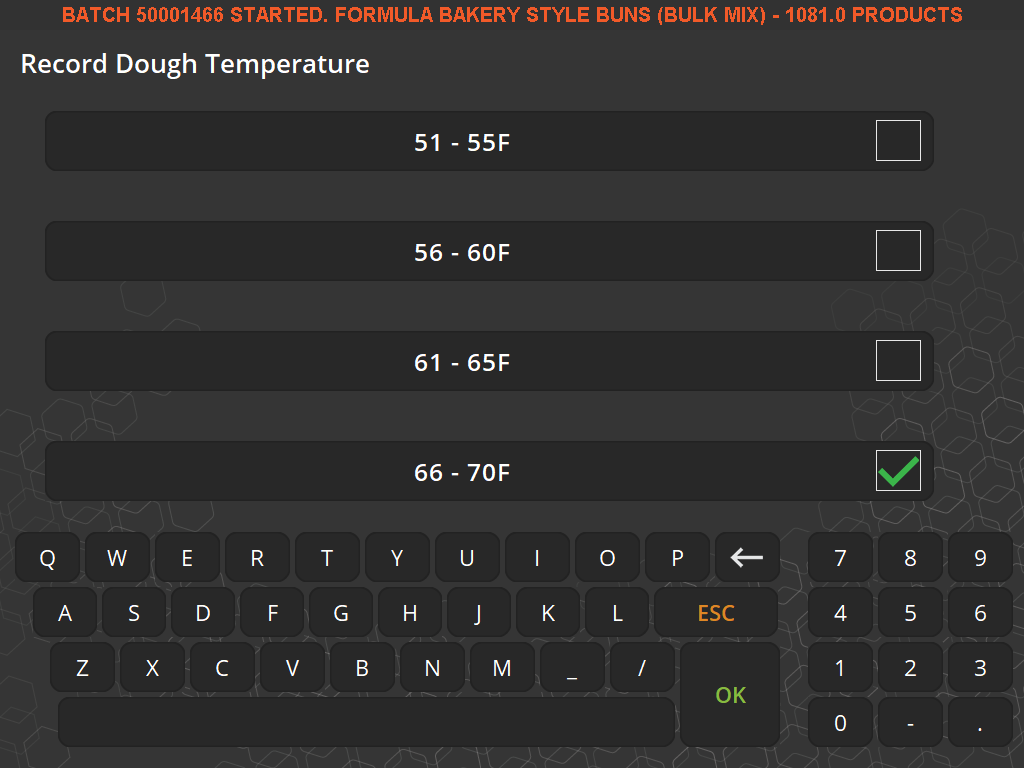

In addition to managing the physical aspects of ingredient handling, these systems are instrumental in ensuring compliance with various quality standards such as BRC, FDA, and FSMA. The ability to automatically control mixes, including ingredient discharge and mixer times, and to work in both automatic and semi-automatic/manual modes, allows for precise control over the production process. This precision is vital not only for quality control but also for meeting the stringent regulatory requirements often encountered in industries dealing with consumables and sensitive products.

Furthermore, the hardware components, like the SG15 Touch Screen, are designed for durability and reliability in harsh manufacturing environments. Their integration with Windows or Linux operating systems and compatibility with various scales and balances make them an essential tool in the modern manufacturing landscape.

In conclusion, Ingredient Management Software is integral to the efficient, accurate, and compliant operation of manufacturing processes, especially in sectors where precision and quality are paramount. These systems provide the necessary tools for accurate ingredient tracking, quality control, and regulatory compliance, making them indispensable in today’s industrial world.