Exploring the V5 Mobile Warehouse Management System

Introduction to V5 Mobile WMS

The V5 Mobile Warehouse Management System (WMS) stands as a beacon of innovation in the realm of inventory control, tailored to meet the dynamic demands of contemporary warehouse environments. Crafted for both agility and efficiency, the V5 Mobile WMS encompasses a broad spectrum of functionalities including comprehensive multi-location inventory oversight, streamlined purchase order processing, meticulous lab testing protocols, proficient sales order management, and the creation of adaptable labeling solutions to cater to various inventory requirements.

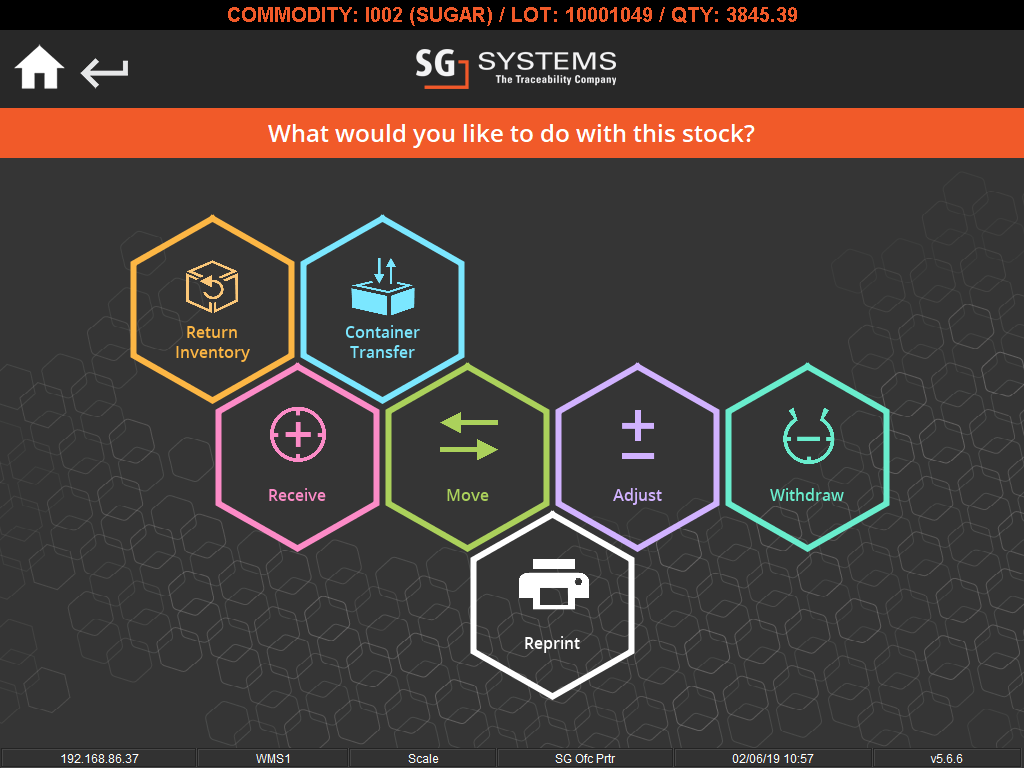

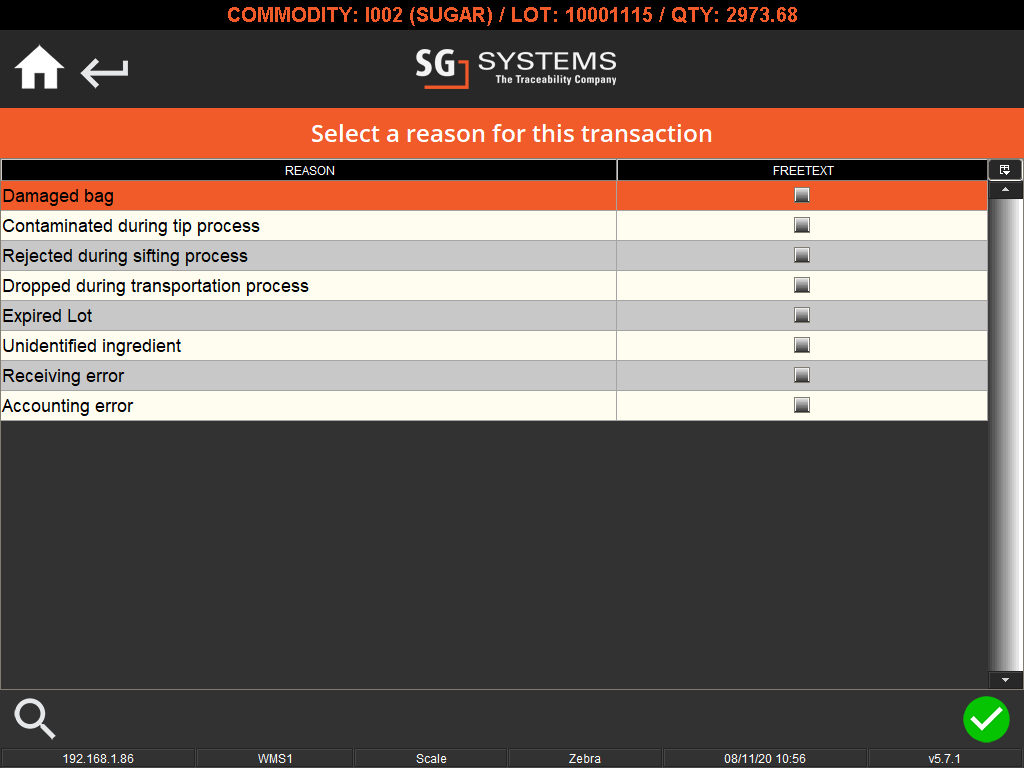

Elevating Inventory Management

At its core, the V5 WMS revolutionizes the approach to inventory management through its intuitive user interface, designed to simplify complex processes such as stock adjustments, the relocation of commodities, and the updating of labels for a diverse range of inventory categories. This user-centric design ensures that even the most intricate inventory tasks are made manageable, enhancing operational efficiency across the board.

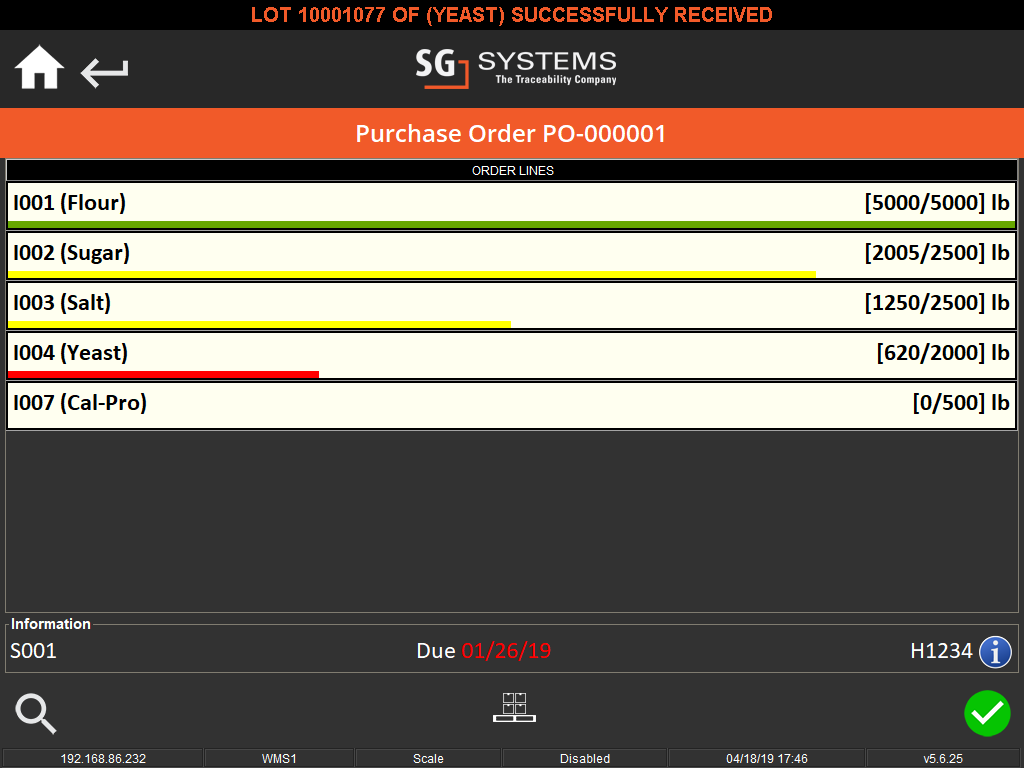

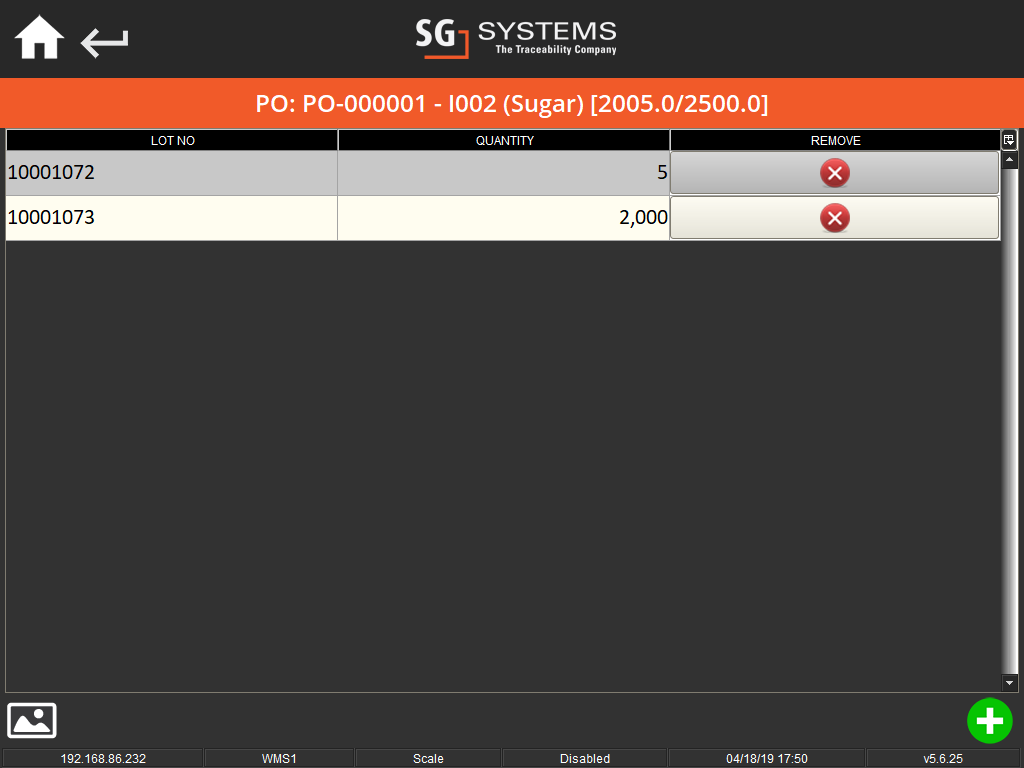

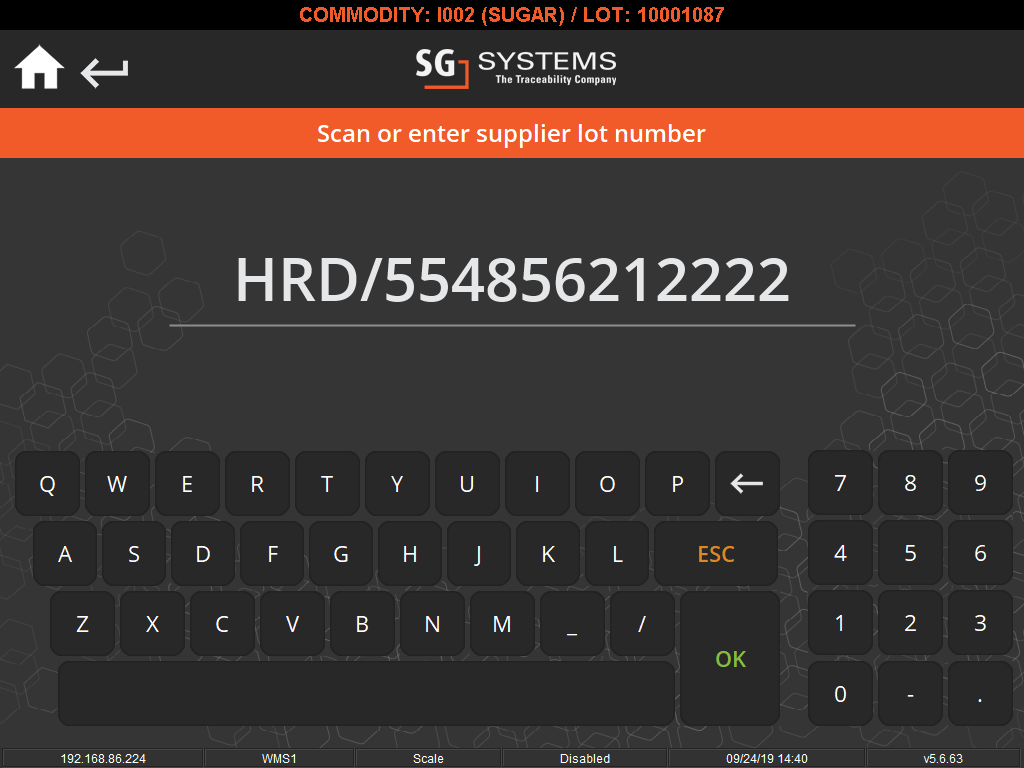

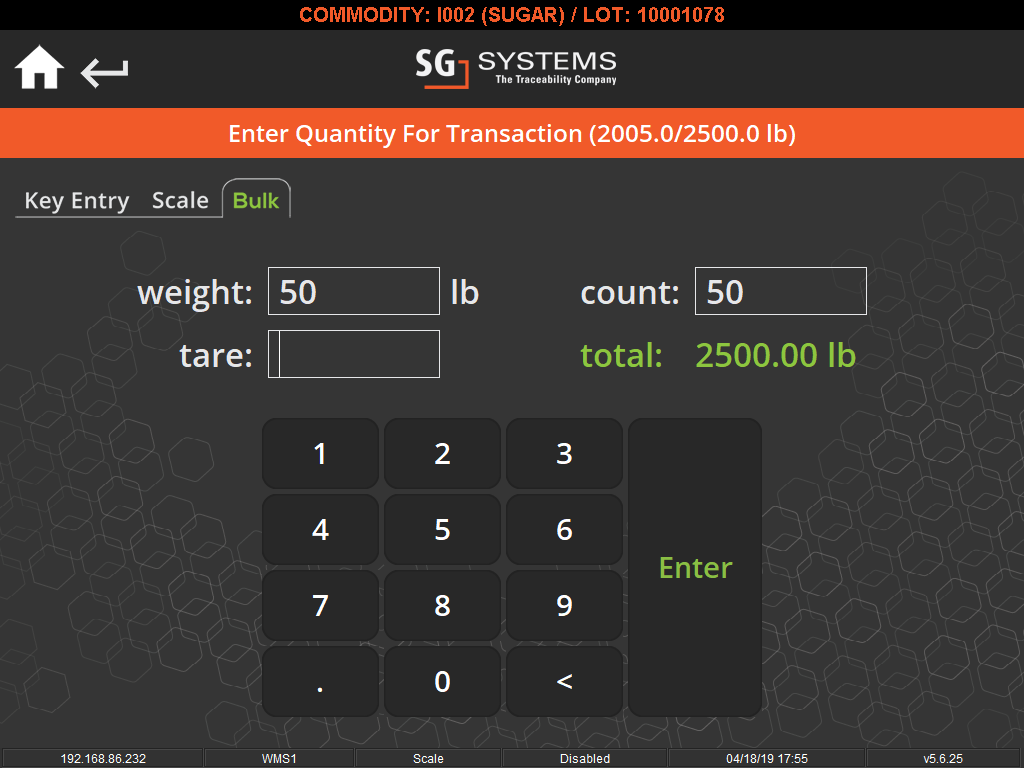

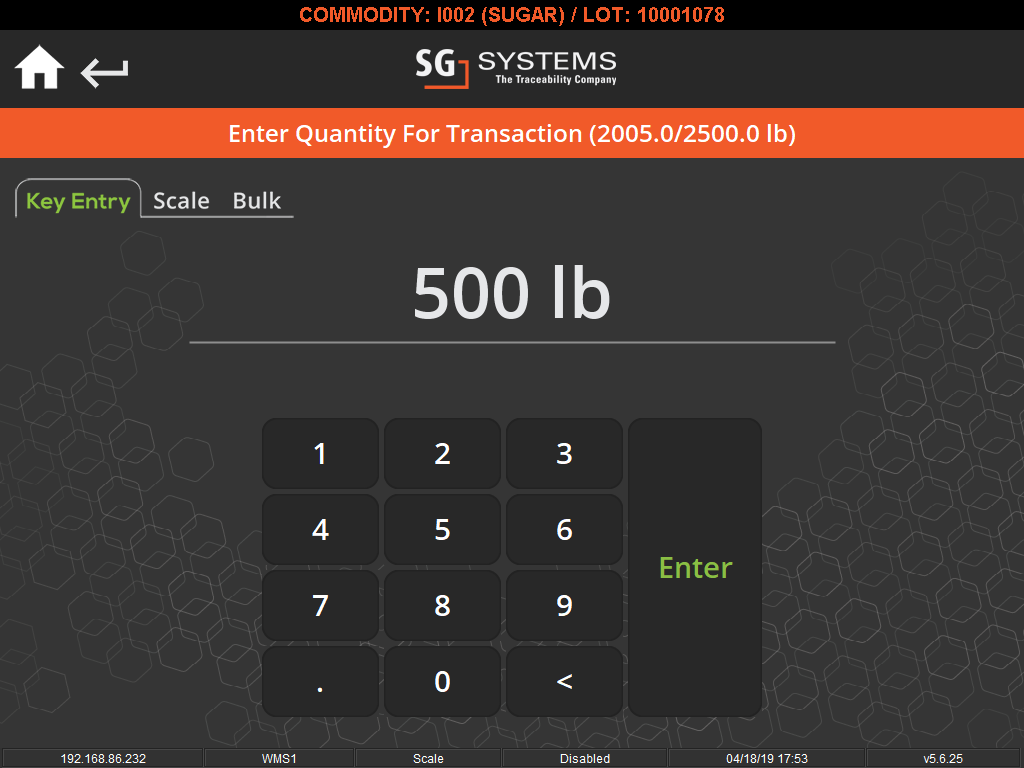

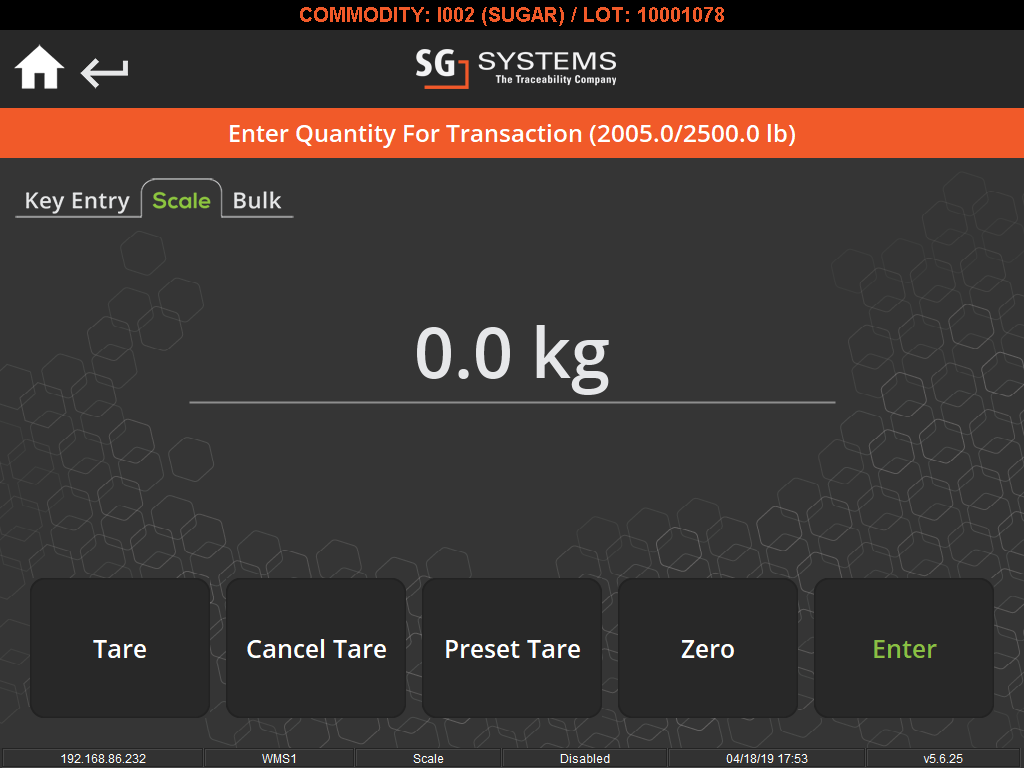

Optimizing Inventory Receiving

The V5 WMS excels in optimizing the receiving process, offering multiple methods to accommodate different types of inventory receipts, including the integration of imported purchase orders and the handling of specific commodity types. This flexibility ensures that the system can adapt to various operational needs, providing real-time updates to inventory levels to maintain accurate and effective stock management.

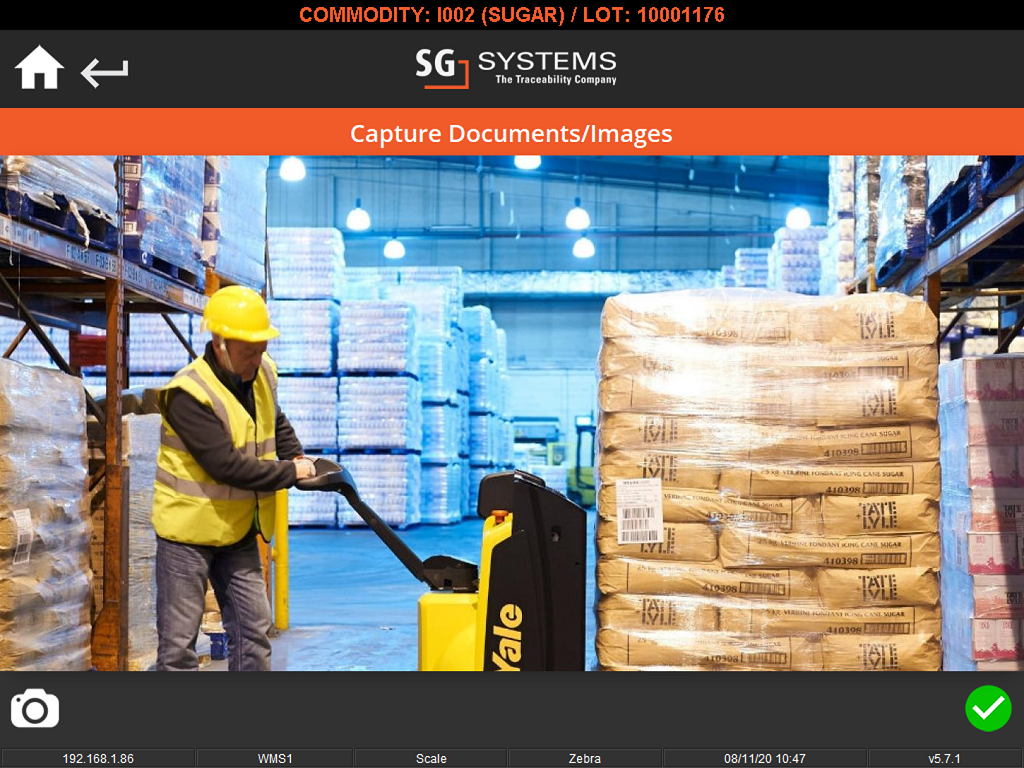

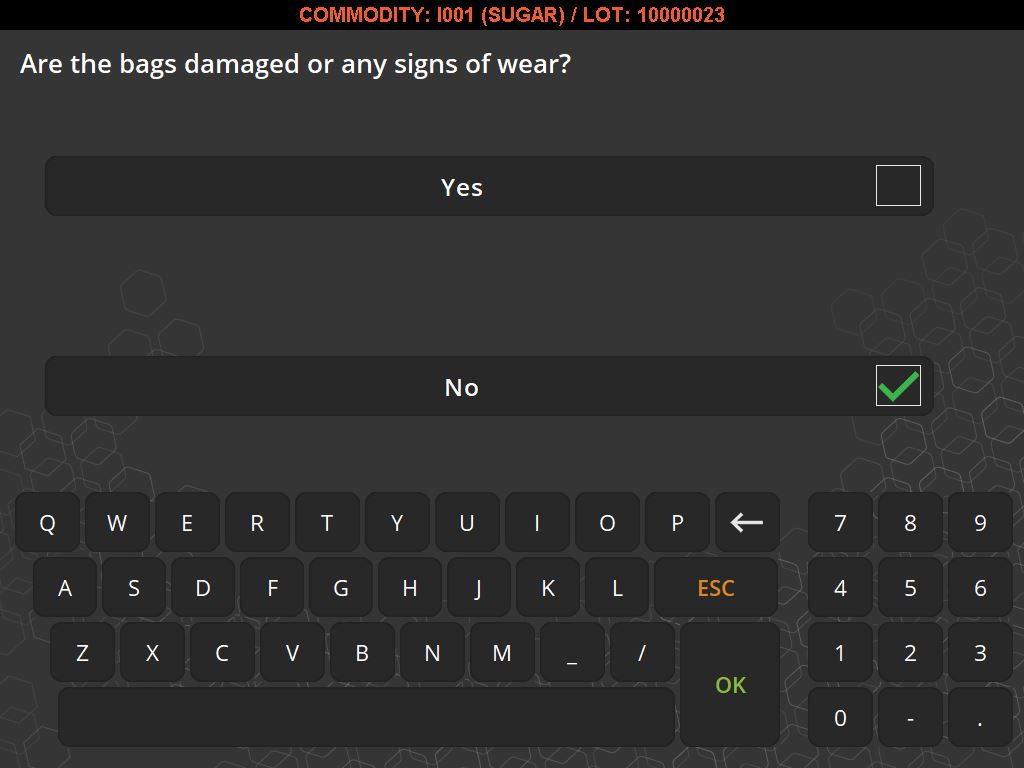

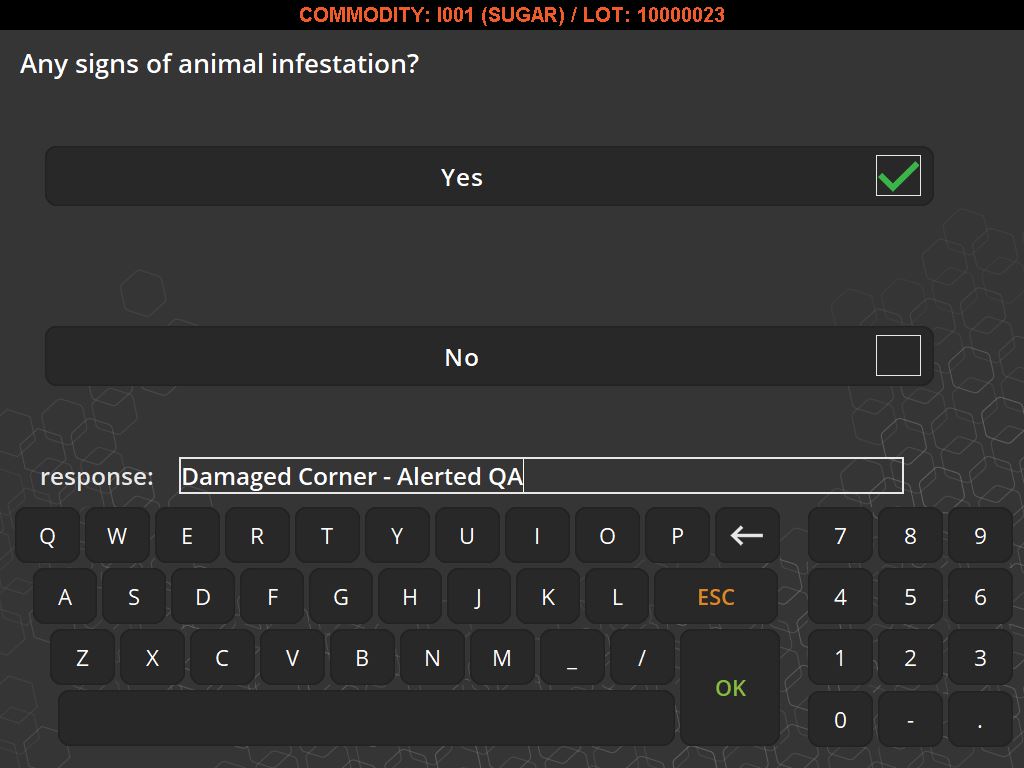

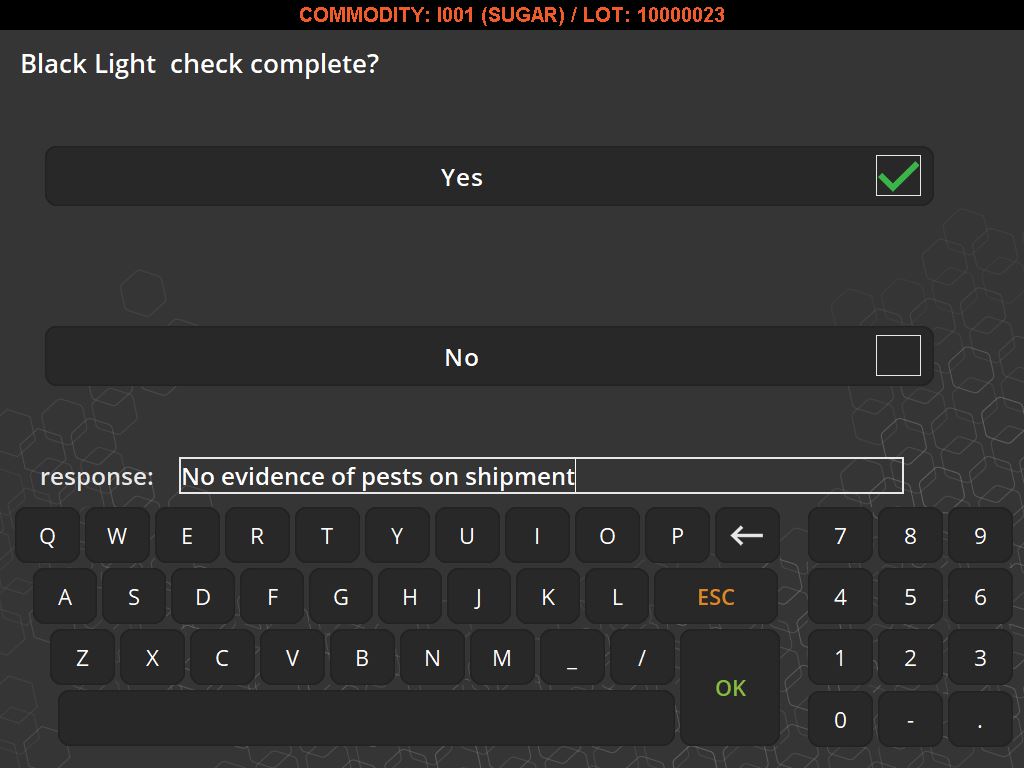

Quality Assurance and Value Addition

The integrated Quality Assurance (QA) module within the V5 WMS minimizes the risk of manual recording errors and captures critical delivery-related data with precision, thereby upholding the highest quality standards across all warehouse operations. This module plays a vital role in ensuring that quality control is not just a process but a foundational element of the inventory management system.

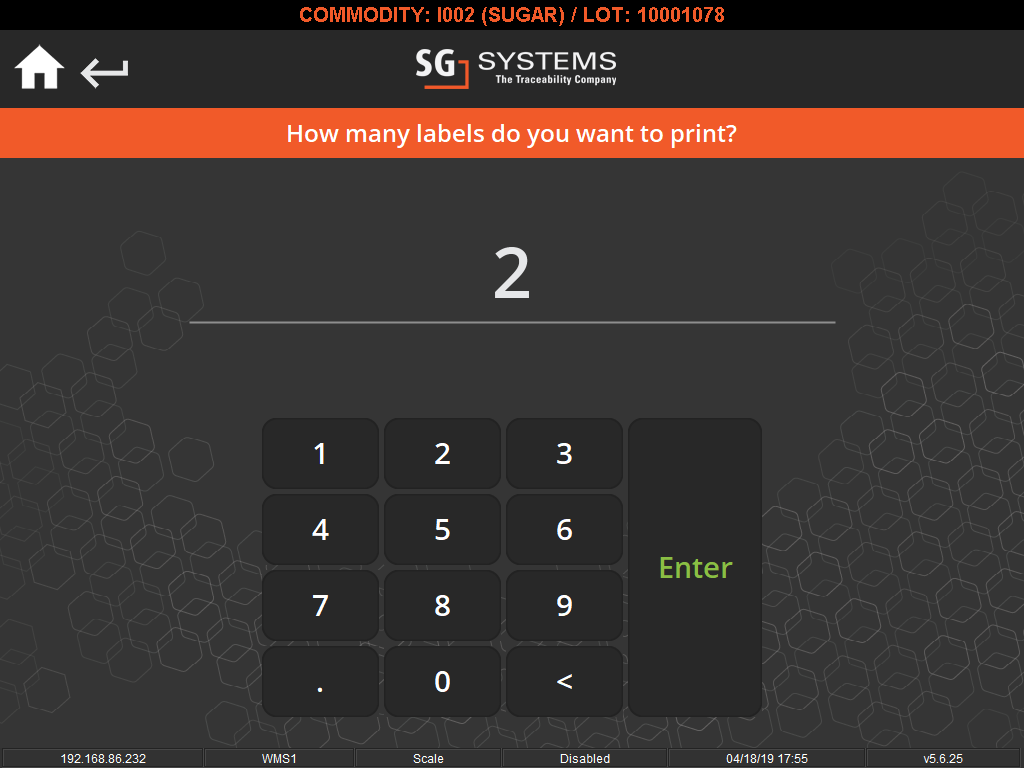

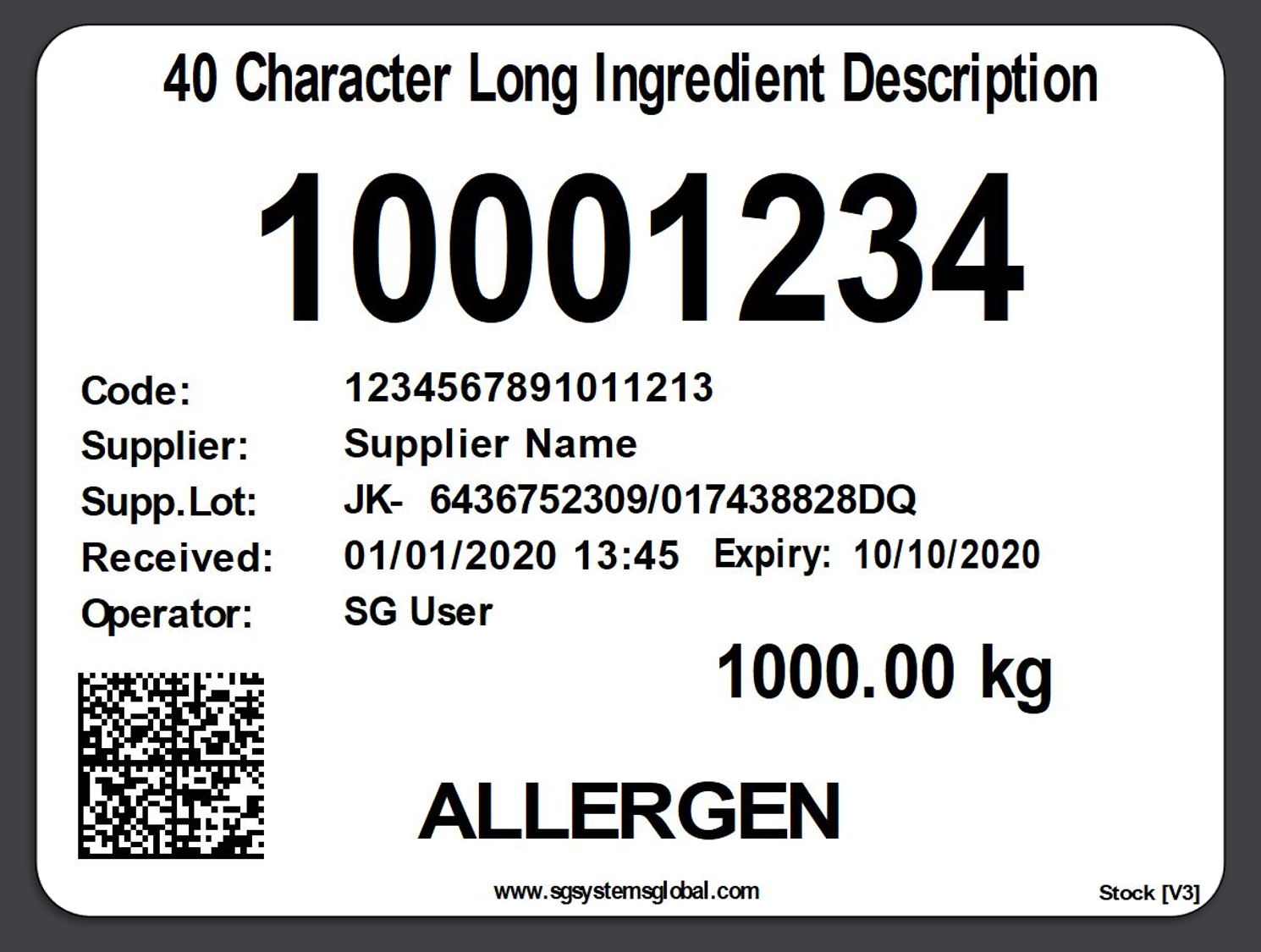

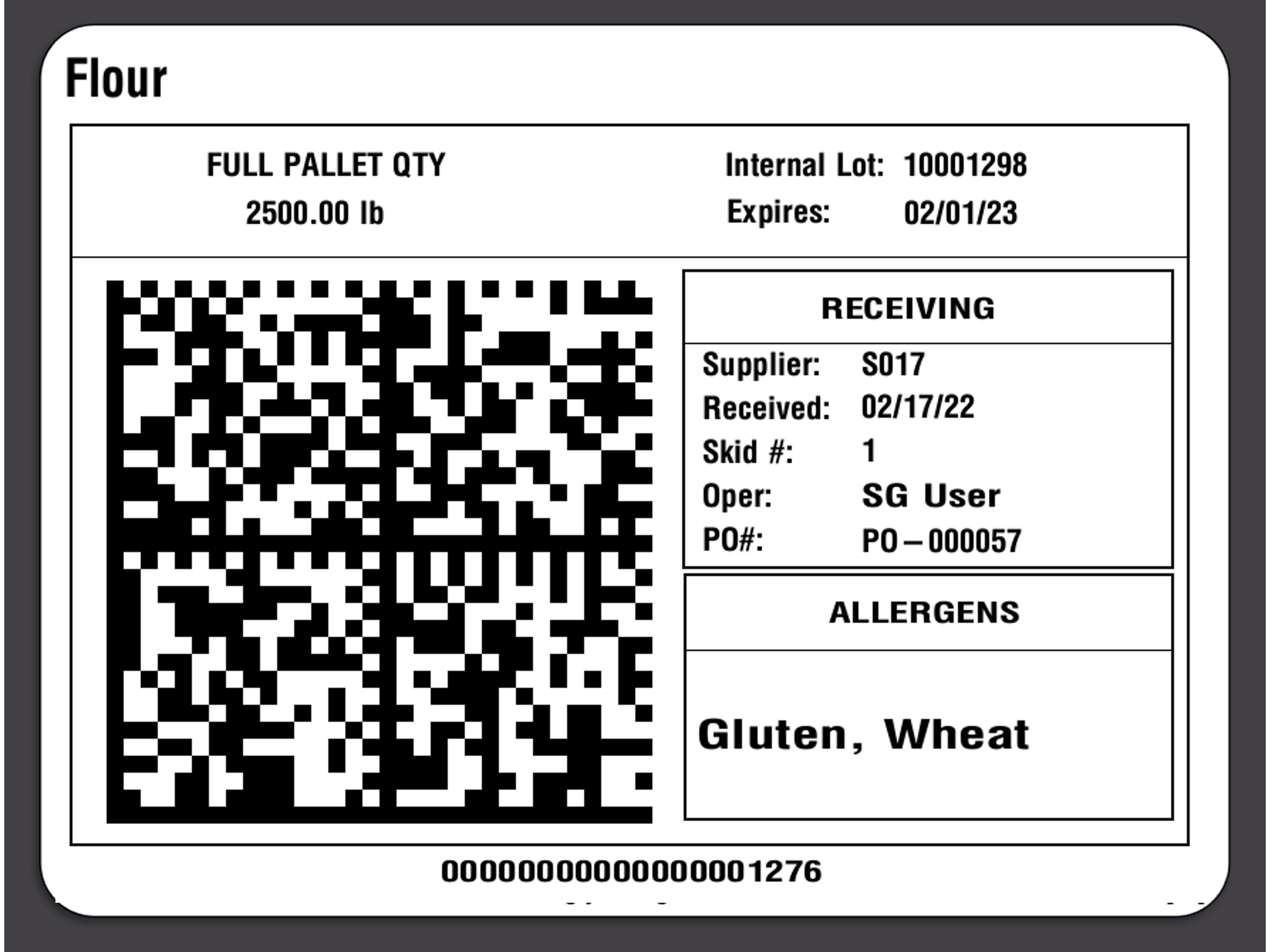

Advanced Labeling Capabilities

V5 WMS’s advanced labeling capabilities allow for the creation of custom labels tailored to specific inventory management needs, including the handling of items requiring special attention such as allergens. This feature underscores the system’s commitment to providing versatile solutions that address the unique challenges faced by warehouse operations.

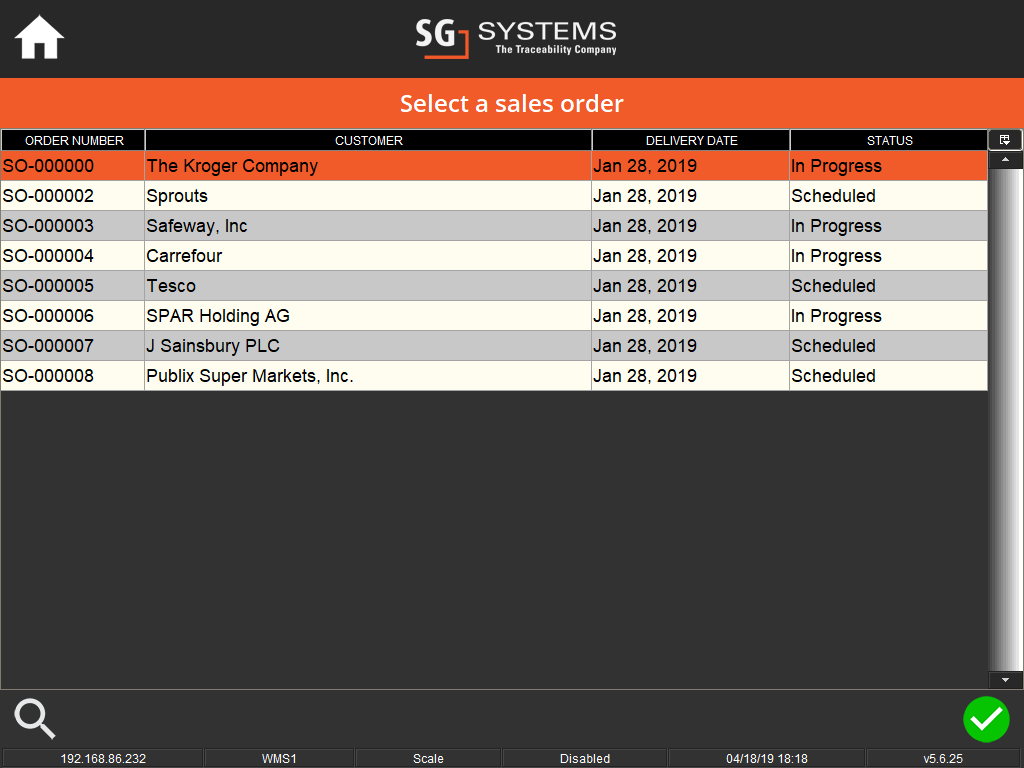

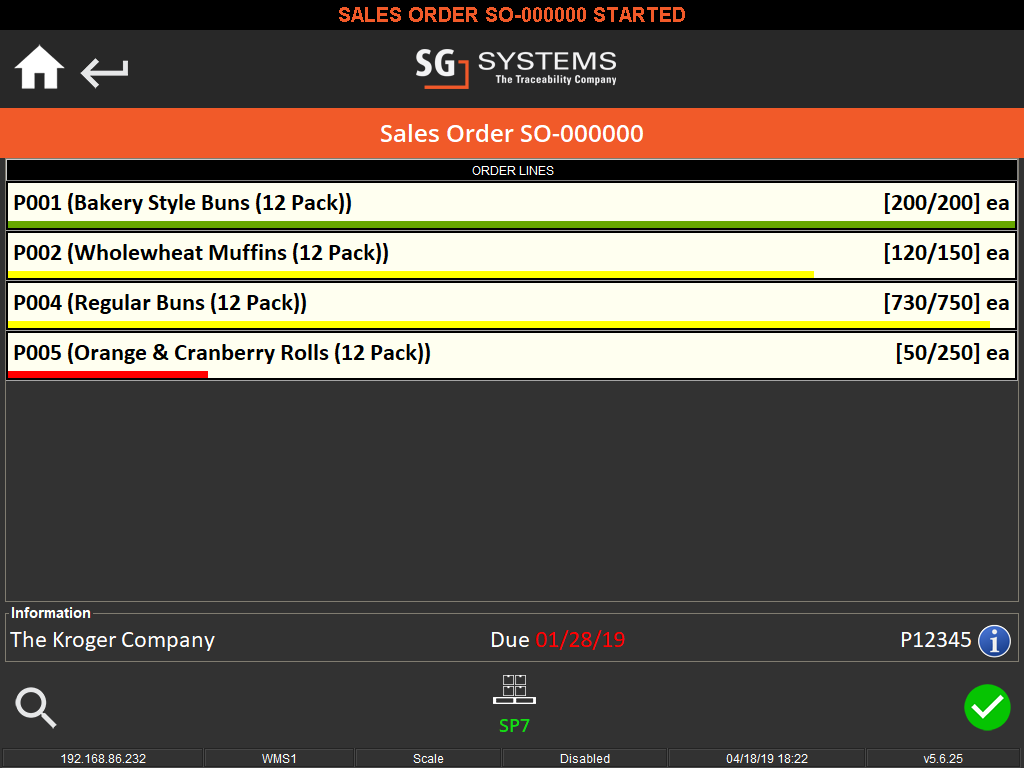

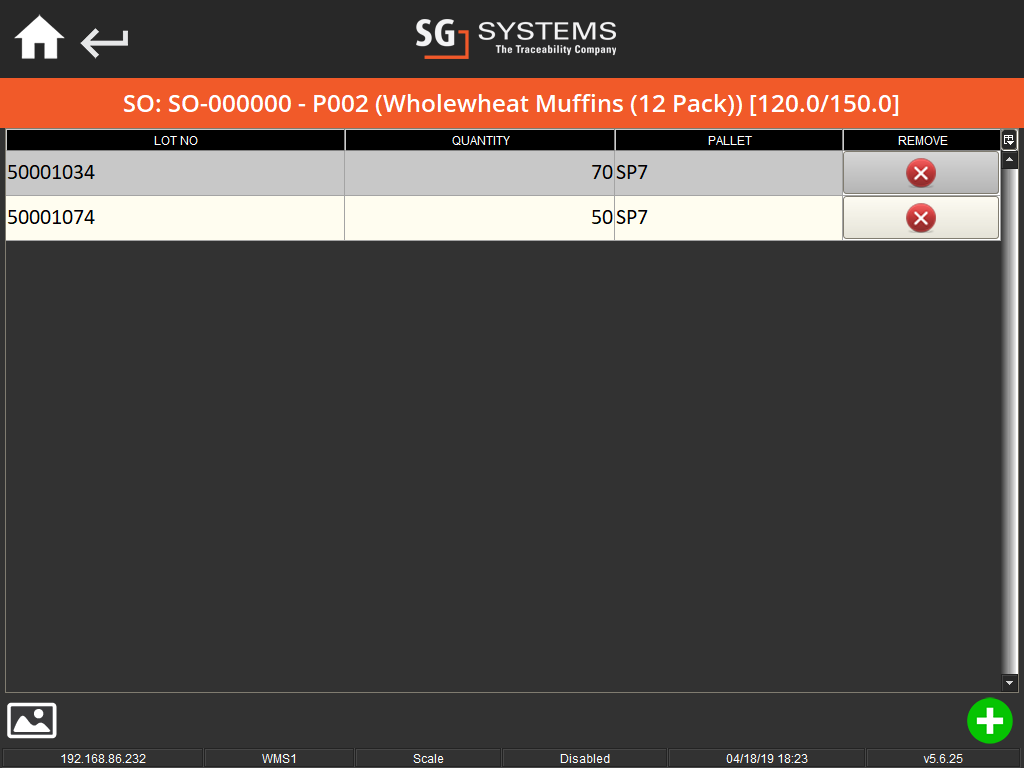

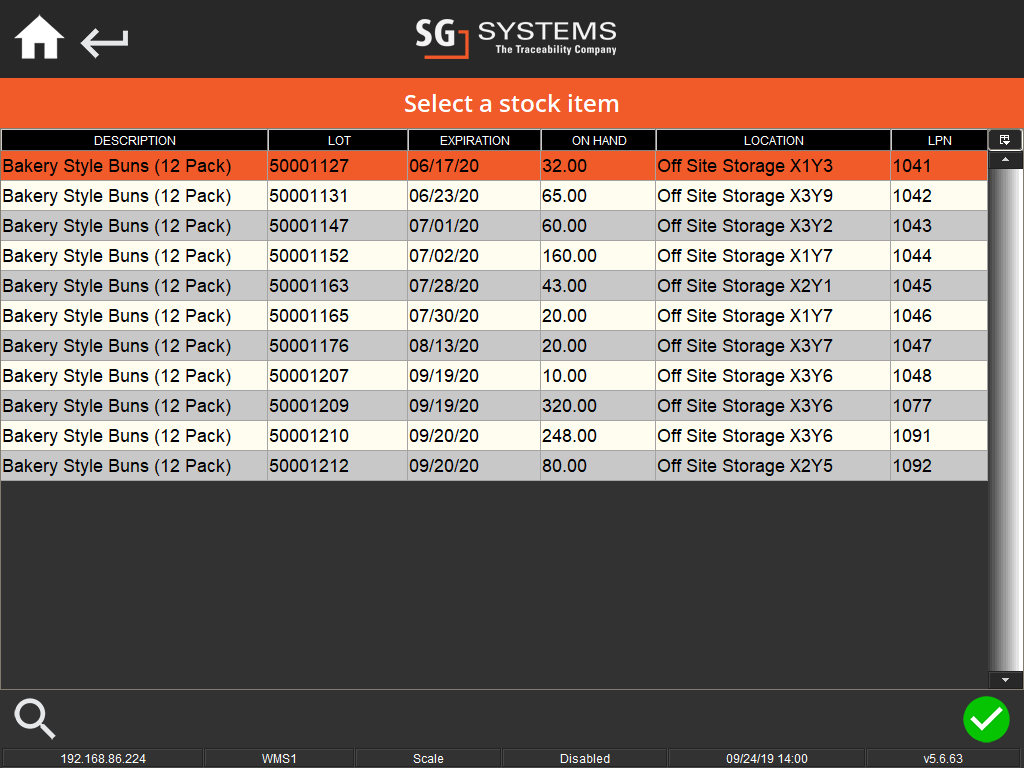

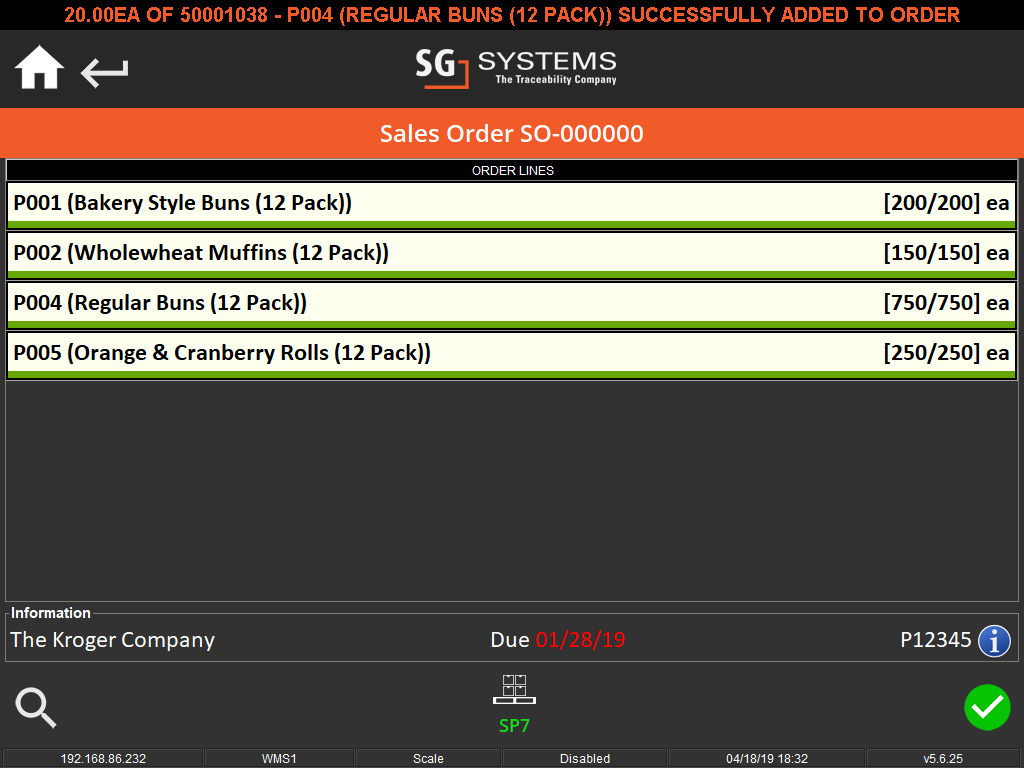

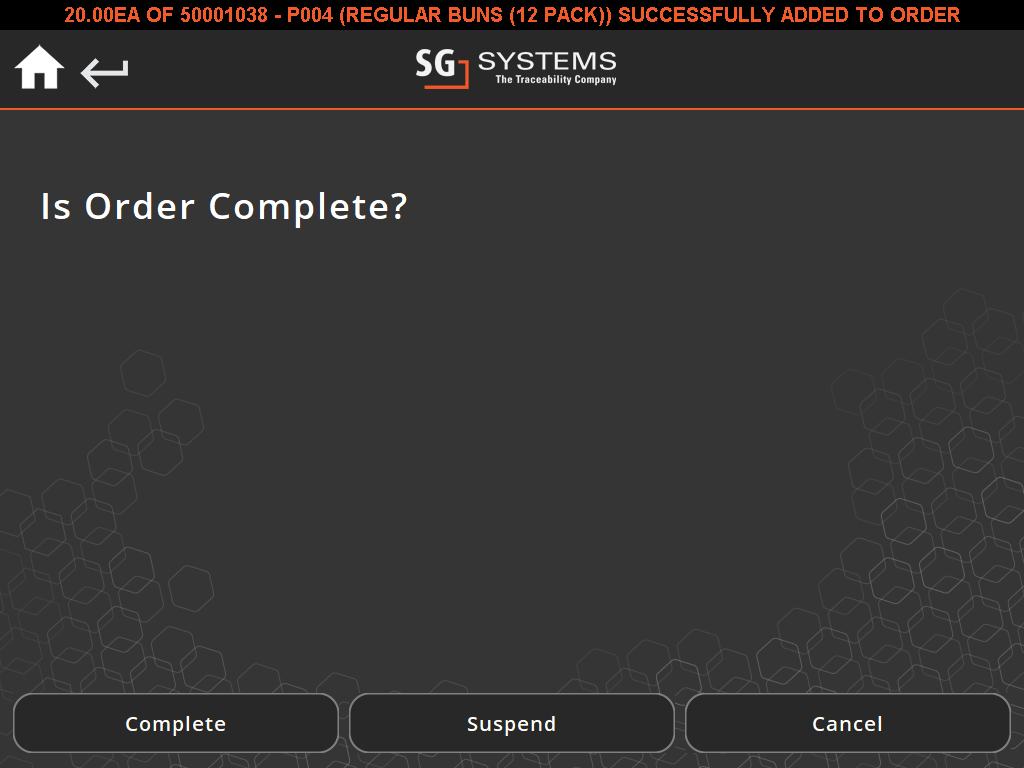

Directed Order Picking Efficiency

The system’s directed order picking feature introduces a structured methodology to the picking process, guiding personnel through each step to ensure the accurate fulfillment of orders while adhering to FIFO (First In, First Out) and FEFO (First Expired, First Out) principles, thereby optimizing order fulfillment processes and enhancing customer satisfaction.

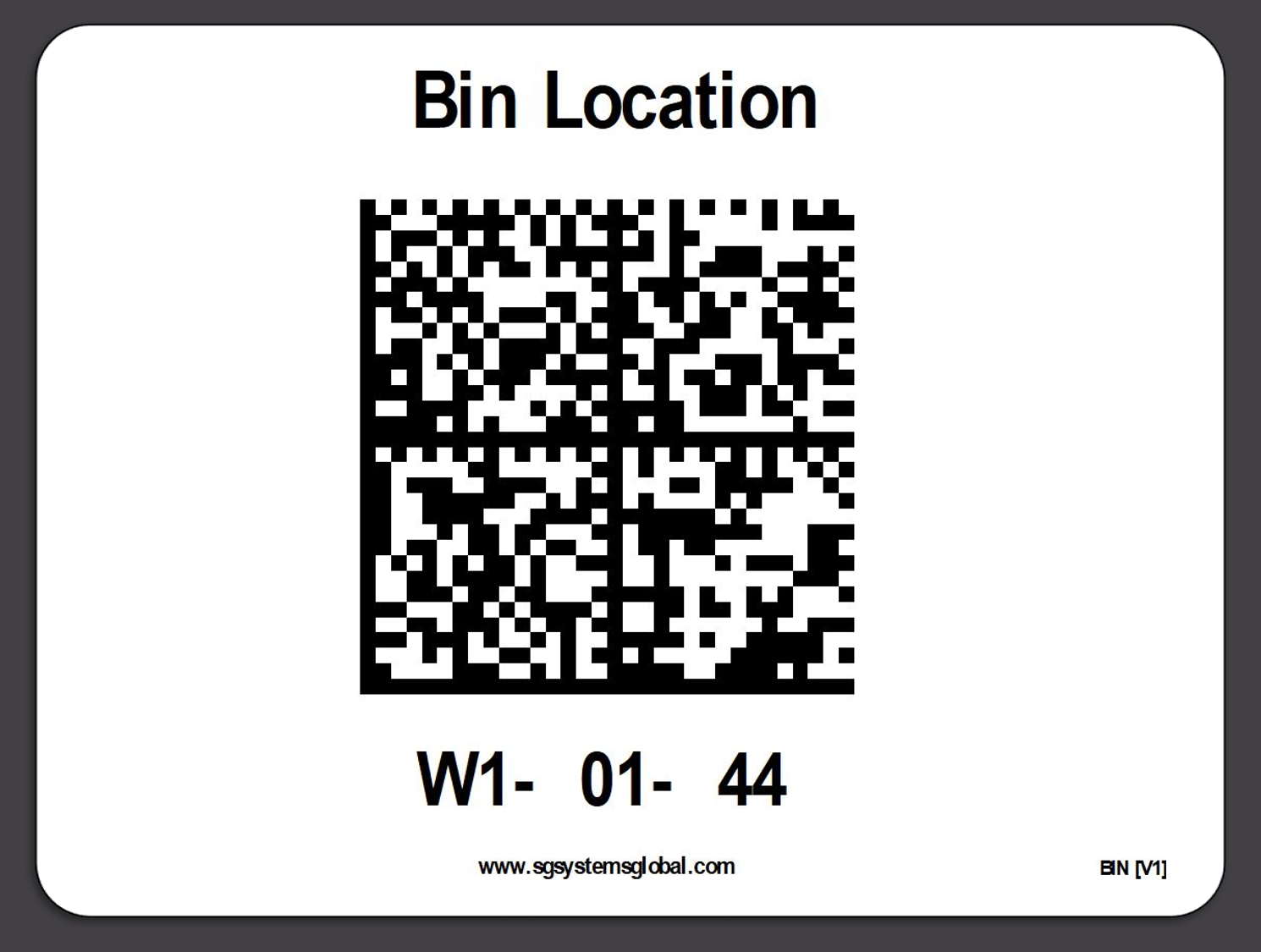

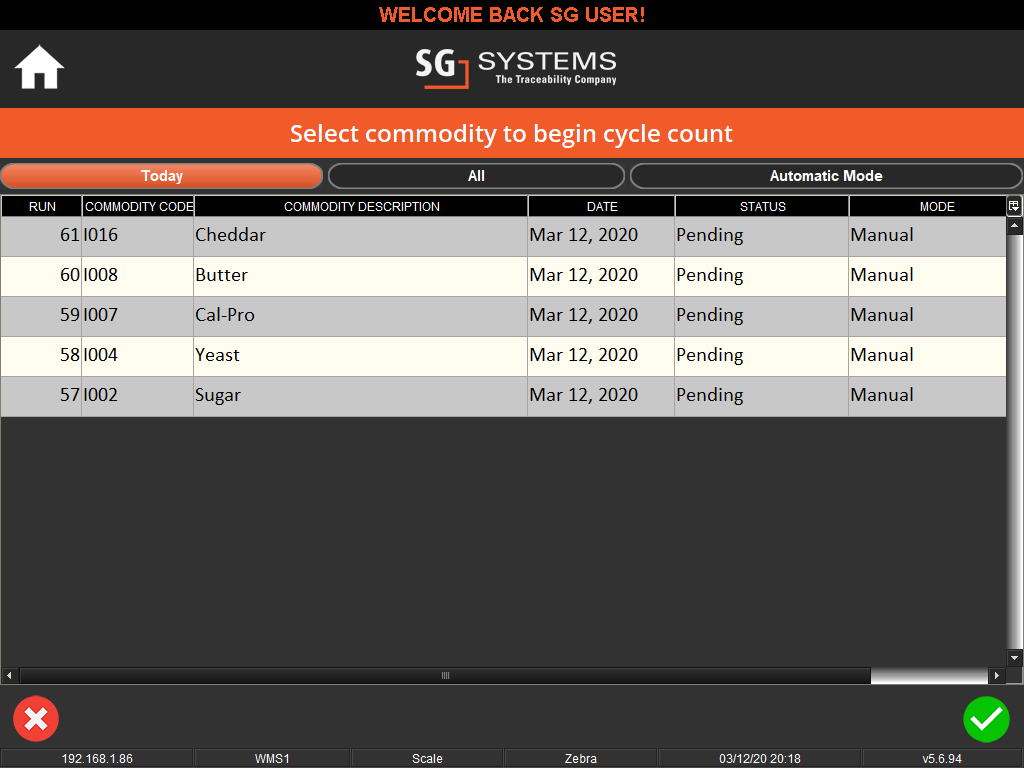

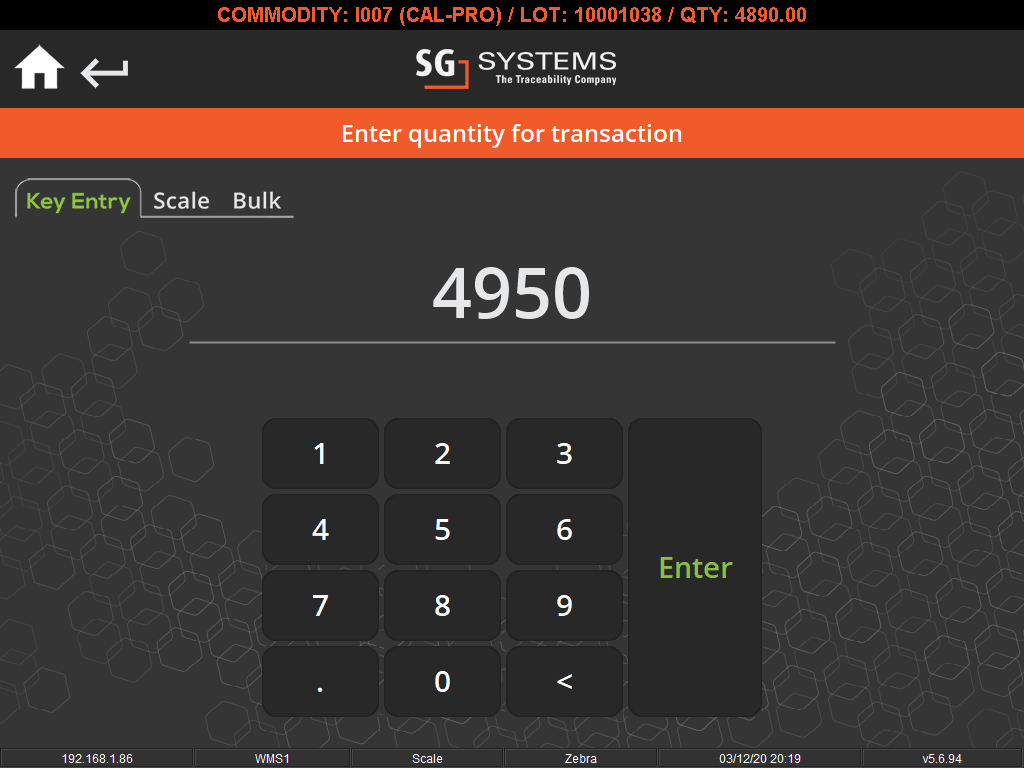

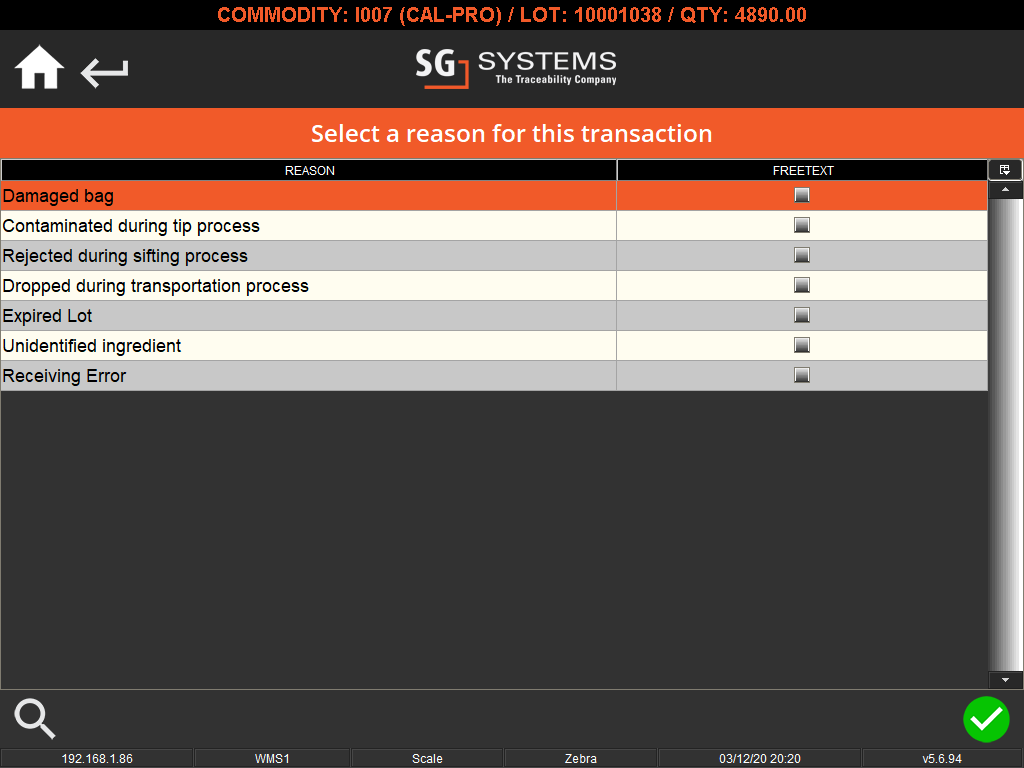

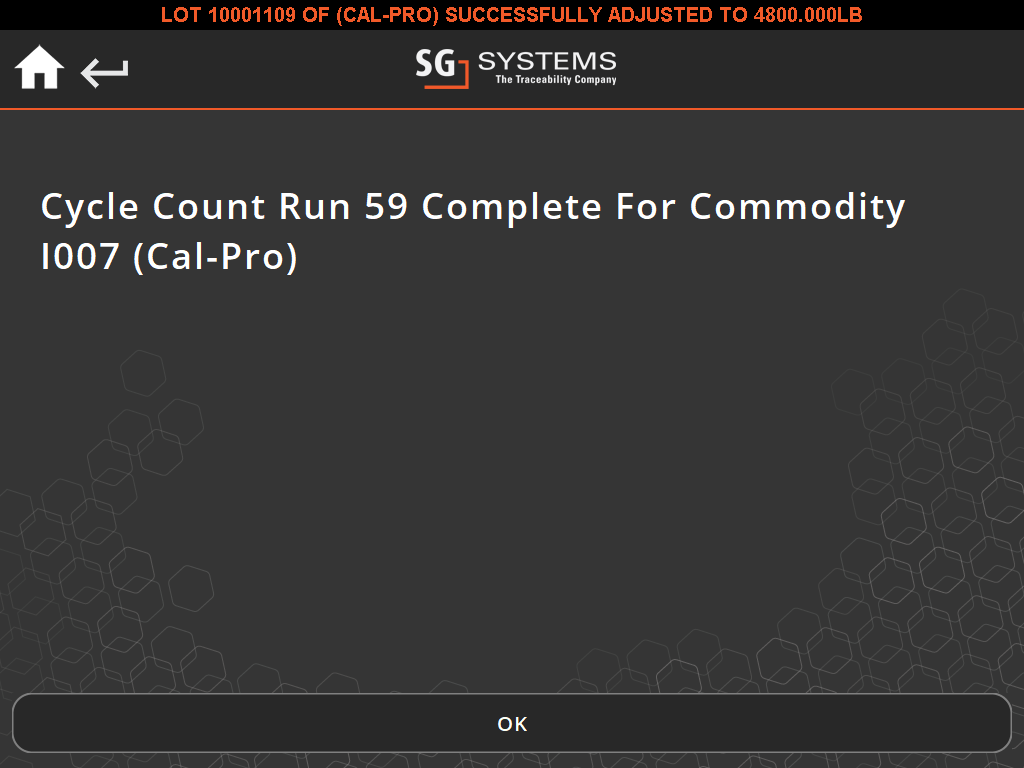

Strategic Scheduled Cycle Count

With the scheduled cycle count feature, V5 WMS offers businesses the ability to strategically manage their inventory through configurable cycle counting activities. This functionality enhances inventory accuracy, providing a solid foundation for effective stock control and operational planning.

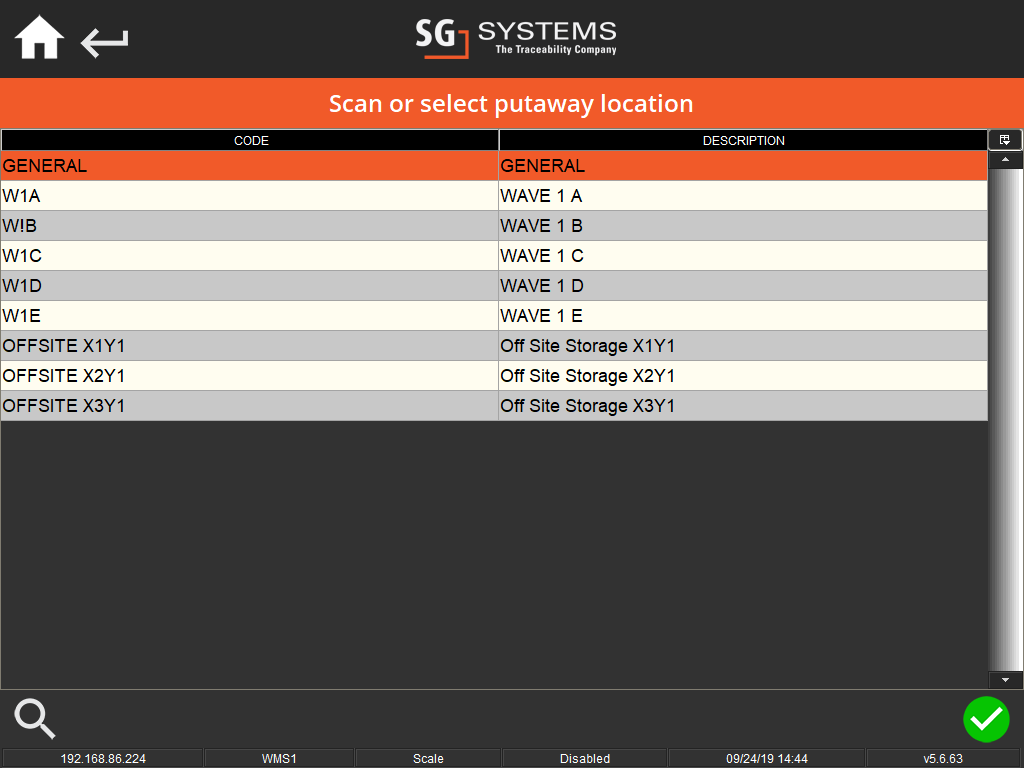

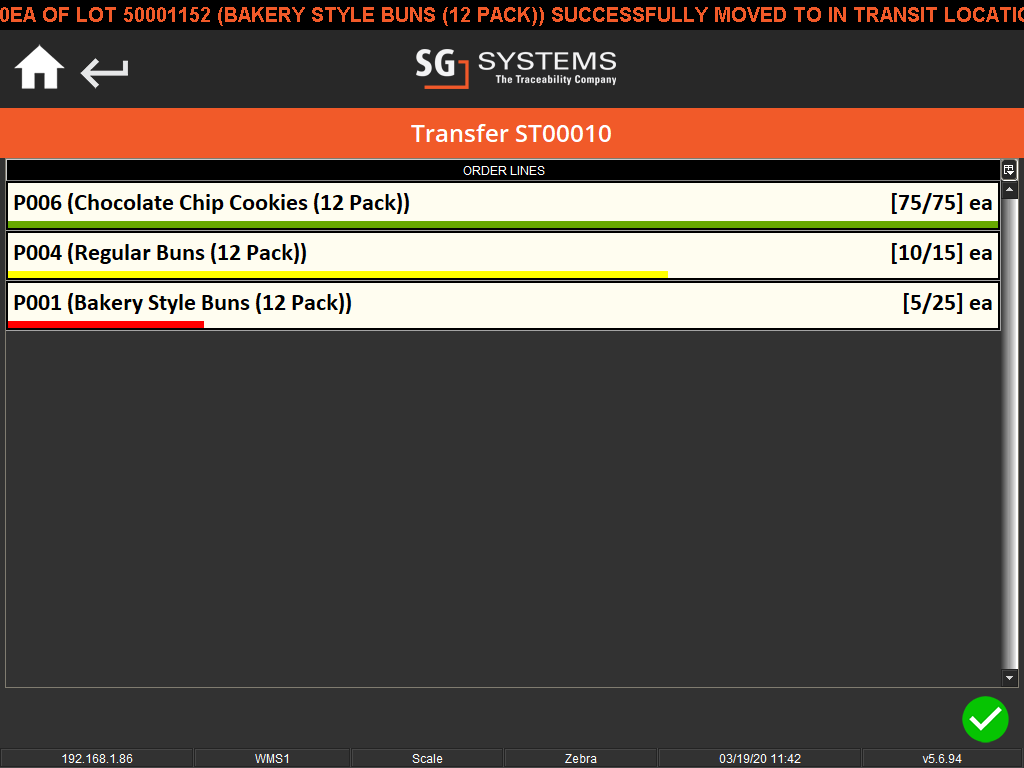

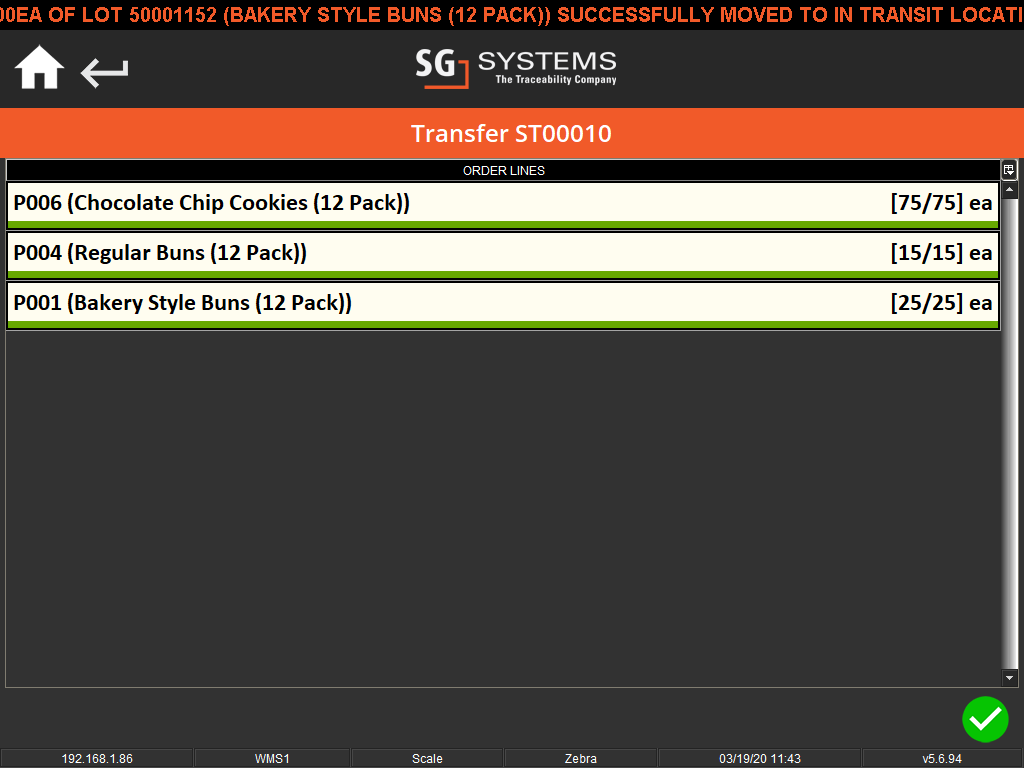

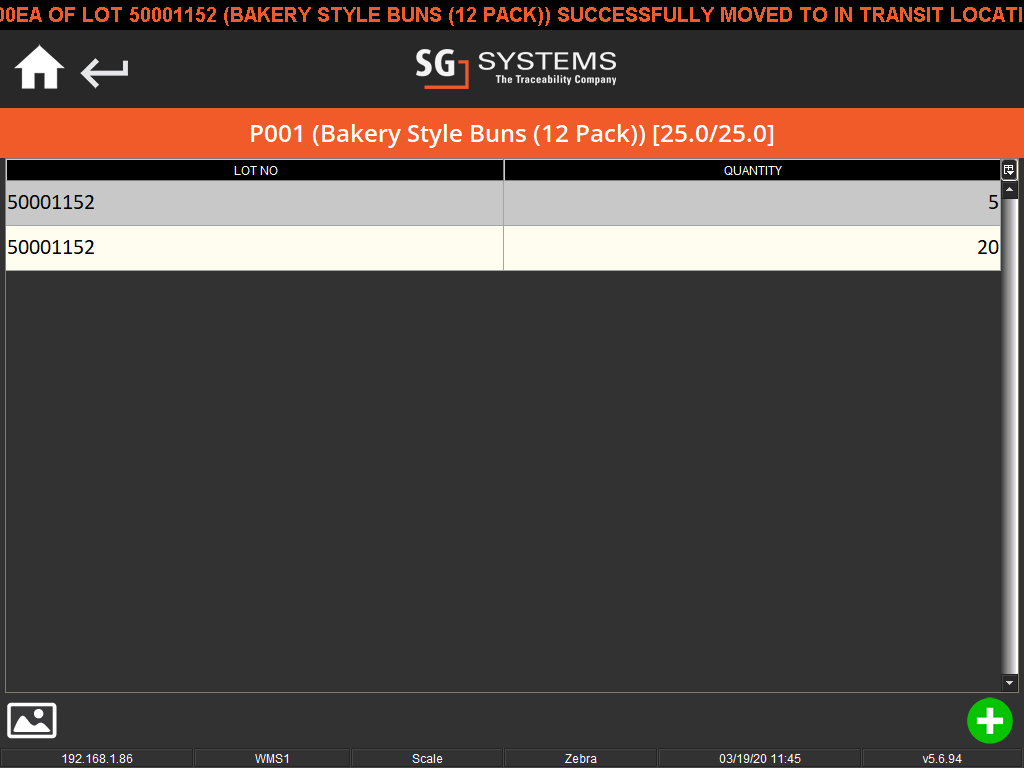

Seamless Scheduled Stock Transfer

The scheduled stock transfer functionality of V5 WMS facilitates the efficient management of inventory across multiple locations, incorporating an ‘IN-TRANSIT’ status to track commodities during transportation. This feature not only streamlines the transfer process but also ensures the electronic recording of critical quality assurance data, maintaining transparency and control throughout the transfer process.

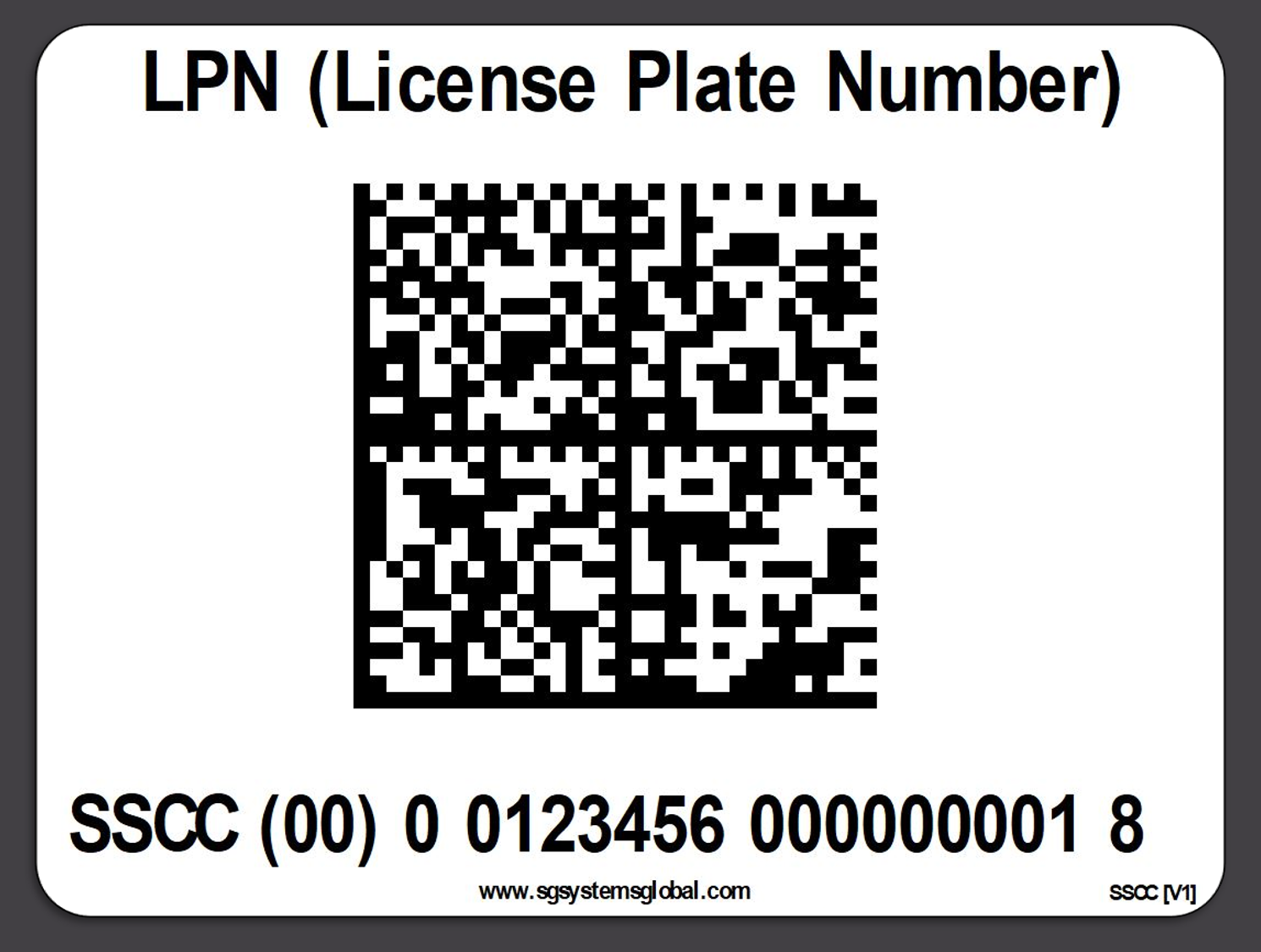

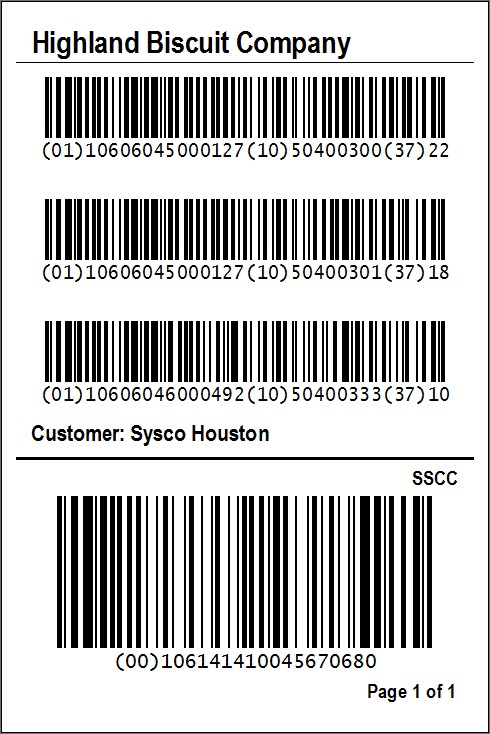

Comprehensive Shipping Label Production

V5 WMS’s capability to produce GS128 compliant shipping labels, including SSCC labels, streamlines the shipping process, ensuring that all outbound shipments are labeled in accordance with international standards. This functionality exemplifies the system’s commitment to facilitating smooth and compliant shipping operations.

Versatile Hardware Compatibility and Networking

Designed to accommodate a variety of operational scales and styles, the V5 WMS is compatible with a wide range of mobile devices and supports multiple networking protocols, ensuring that businesses of all sizes can leverage its comprehensive warehouse management solutions.

Real-Time Inventory Updates and Sales Order Management

Key features of V5 WMS include real-time inventory updates, which are crucial for maintaining accurate stock records, and the ability to handle the creation and importation of sales orders, streamlining the sales management process and enhancing operational efficiency.

Configurable Inventory Filtering and Accurate Order Picking

The system offers configurable options for inventory filtering, aiding in efficient inventory management, and employs advanced barcode scanning technology to ensure accuracy during the order-picking process, thereby guaranteeing precision in order fulfillment.

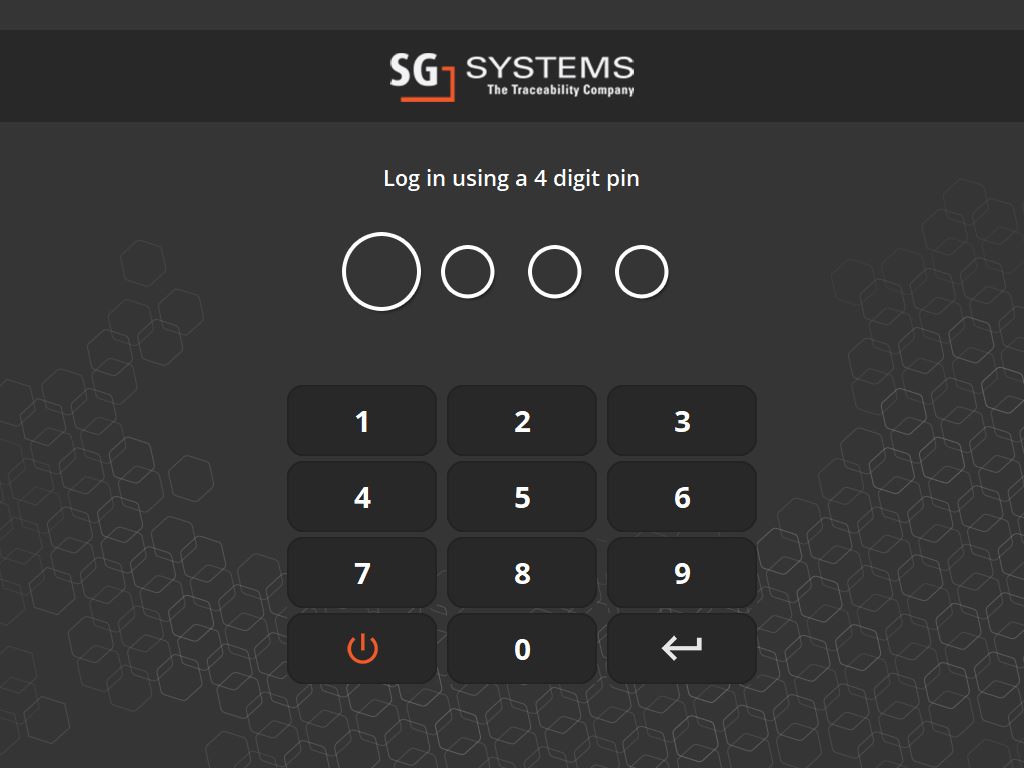

User-Friendly Interface and Comprehensive Quality Control

V5 WMS is renowned for its user-friendly interface, enhancing ease of use and operational efficiency. Additionally, the system integrates functionalities for managing lab testing and Certificates of Analysis, supporting rigorous quality control and compliance measures.

EDI and Supply Chain Communication

The V5 WMS supports Electronic Data Interchange (EDI) and Advanced Shipping Notices (ASN), enhancing electronic communication within the supply chain and streamlining the exchange of critical shipping information.

Allergen Management and Business Scalability

Features for allergen management within V5 WMS ensure the safe handling of allergen-containing commodities, while the system’s scalability makes it suitable for a wide array of businesses, from small operations to large enterprises, offering flexible solutions to meet diverse warehouse management needs.