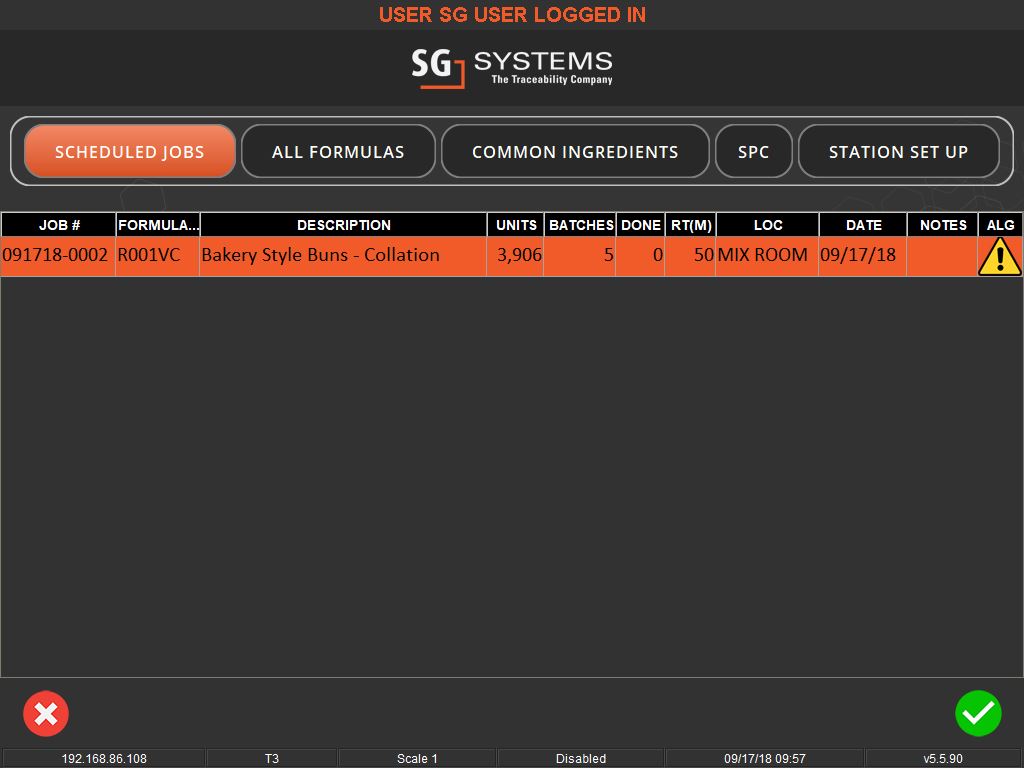

Comprehensive Integration for Streamlined Operations:

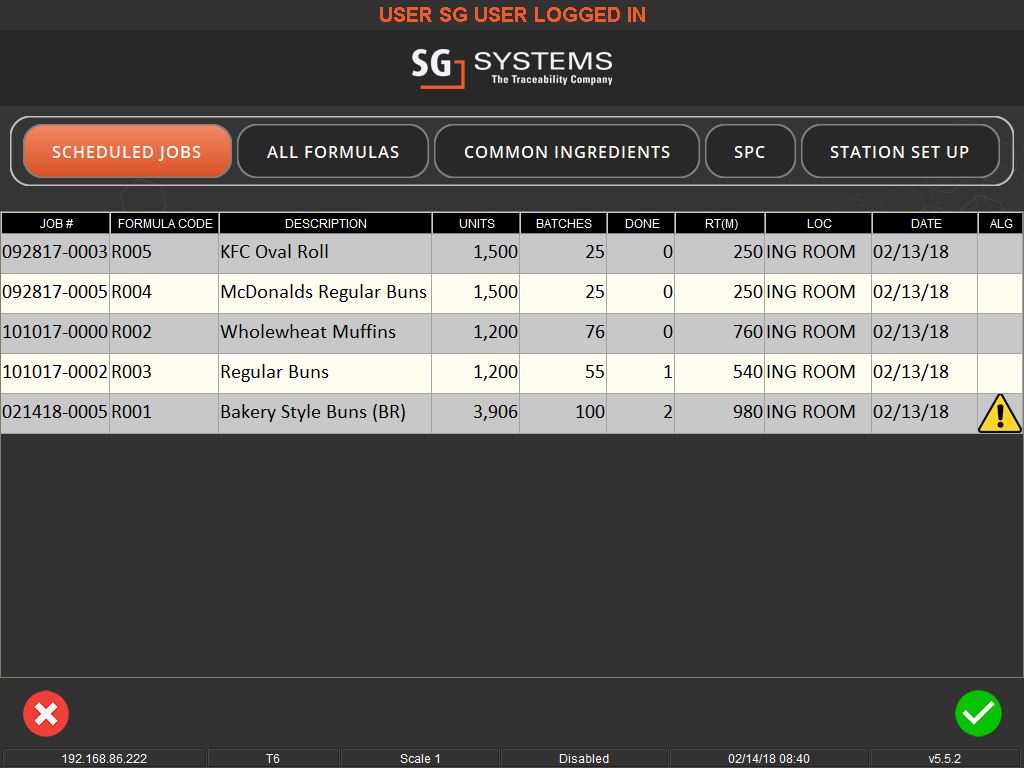

NetSuite’s integration with SG Systems Global’s V5 Traceability software transforms the way companies manage their manufacturing and supply chain processes. From real-time data exchange to multi-level Bill of Materials (BOMs) and schedules, this combination offers a tailored solution for data mapping and transfer. Businesses leveraging this integration benefit from increased accuracy, efficiency, and seamless operations from receiving to shipping.

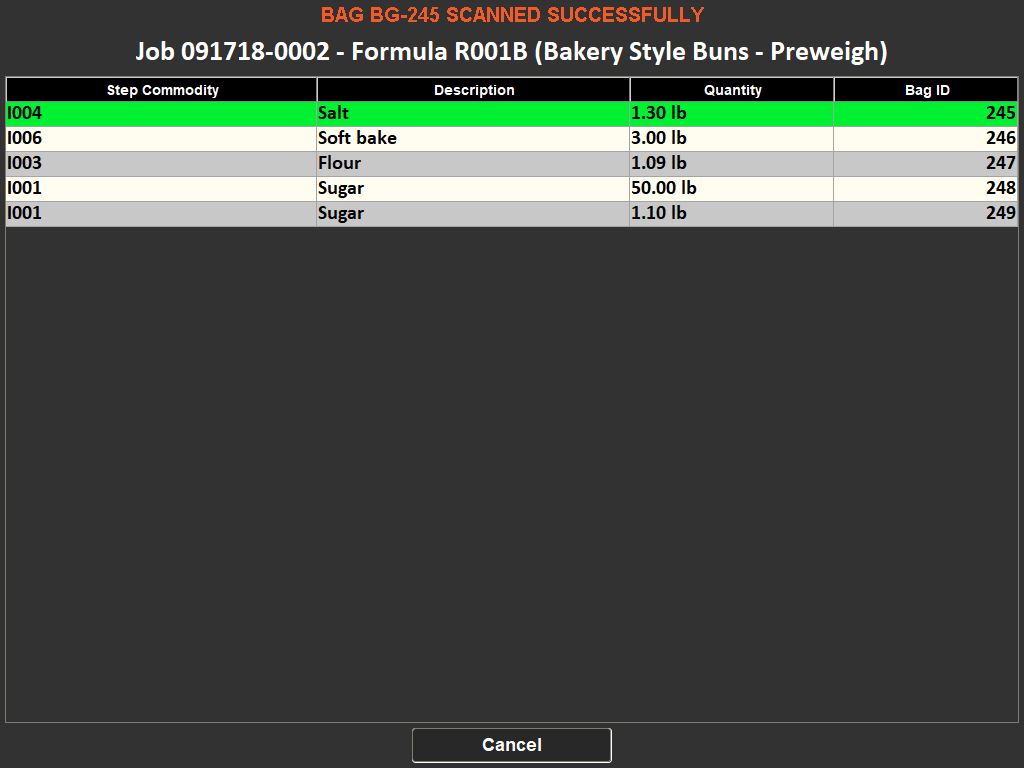

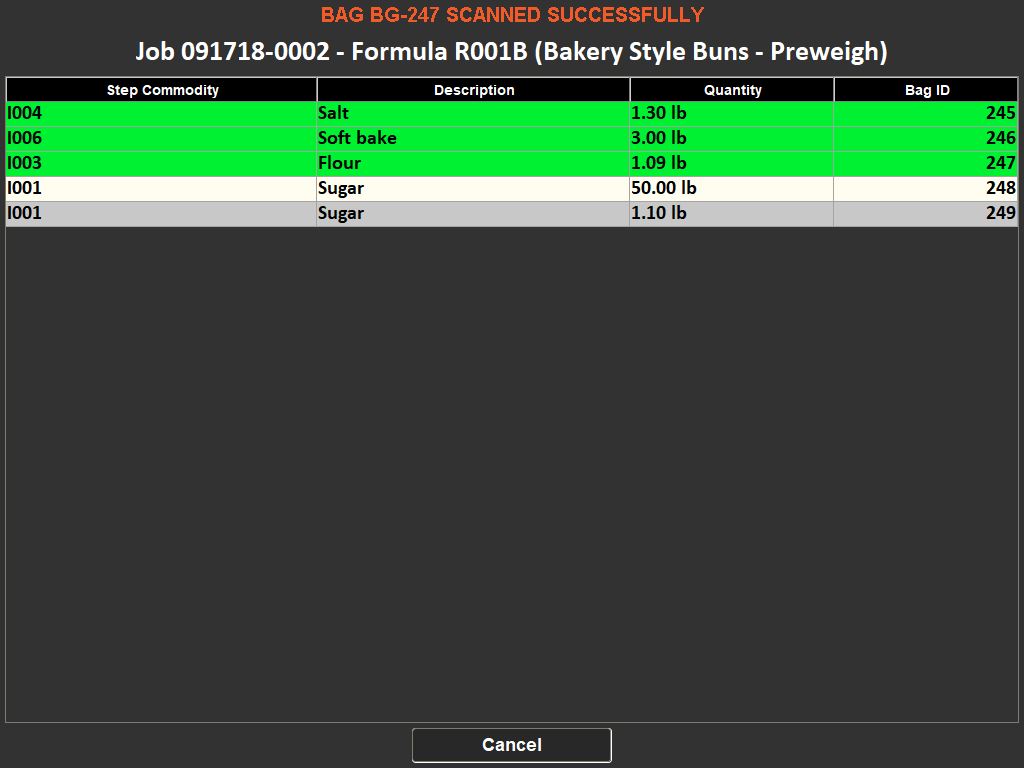

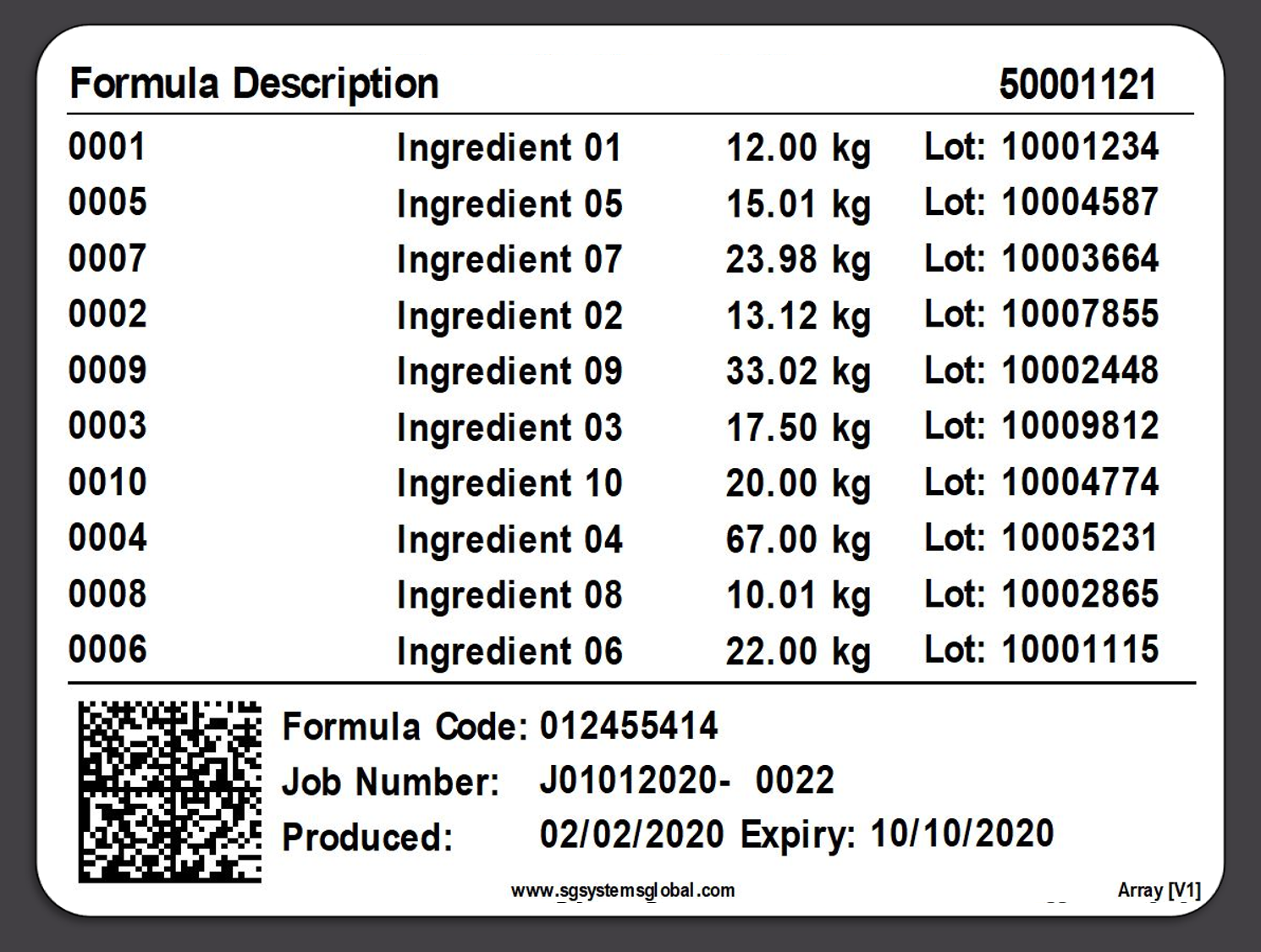

Innovative Traceability for Manufacturing Industries:

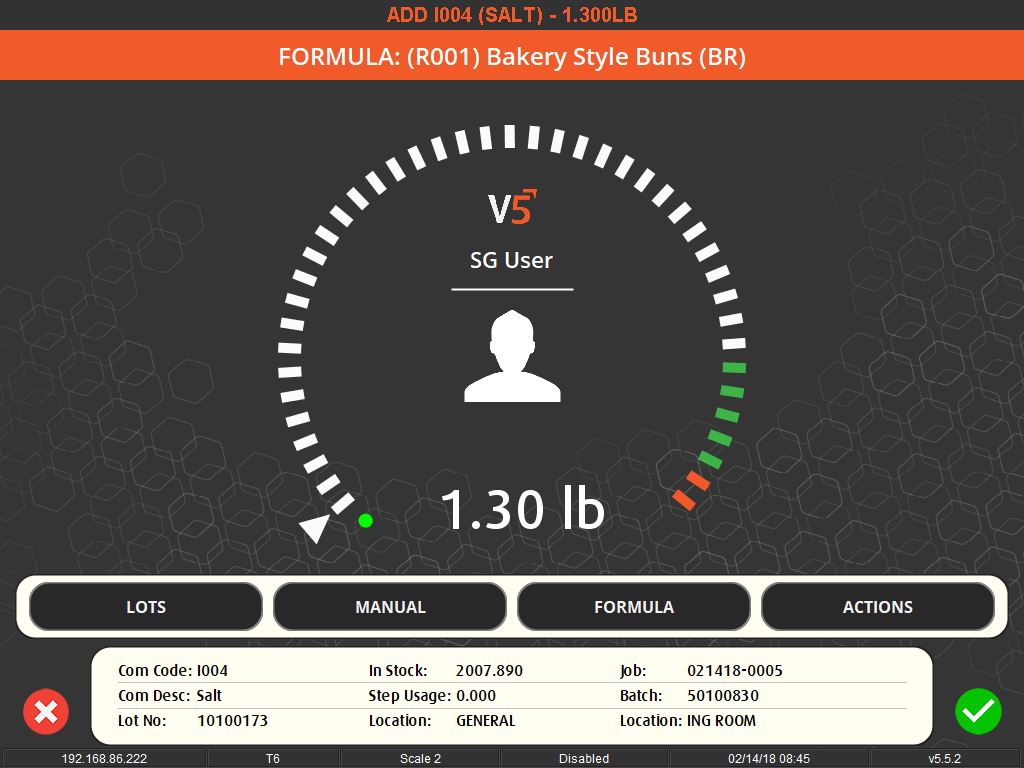

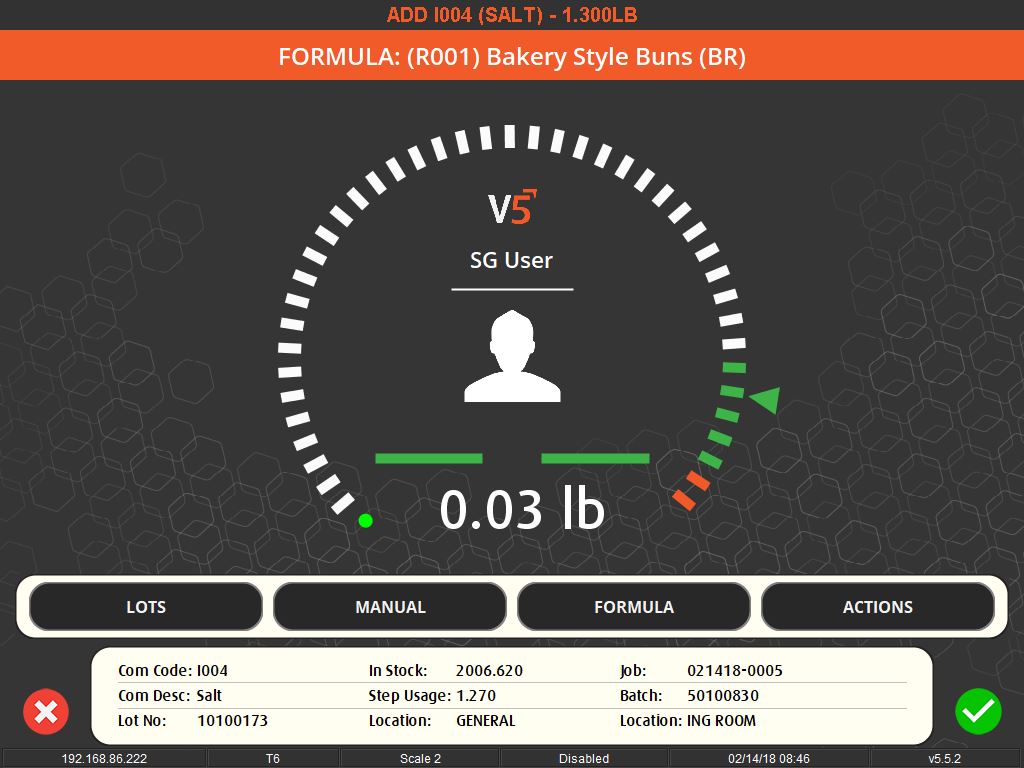

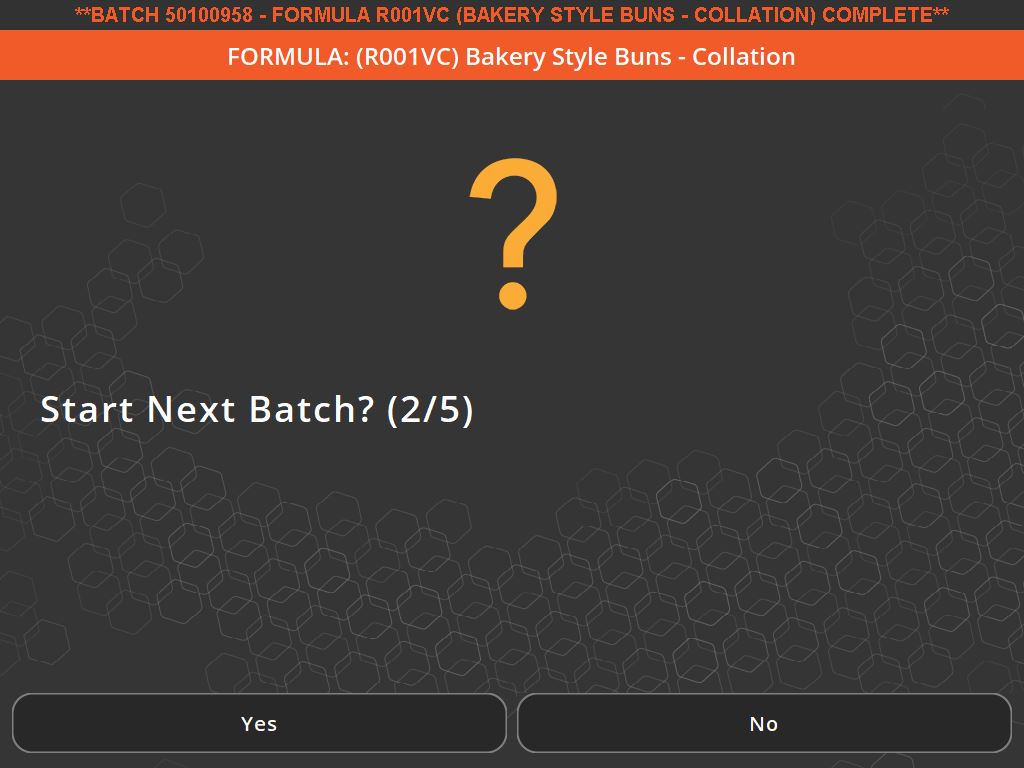

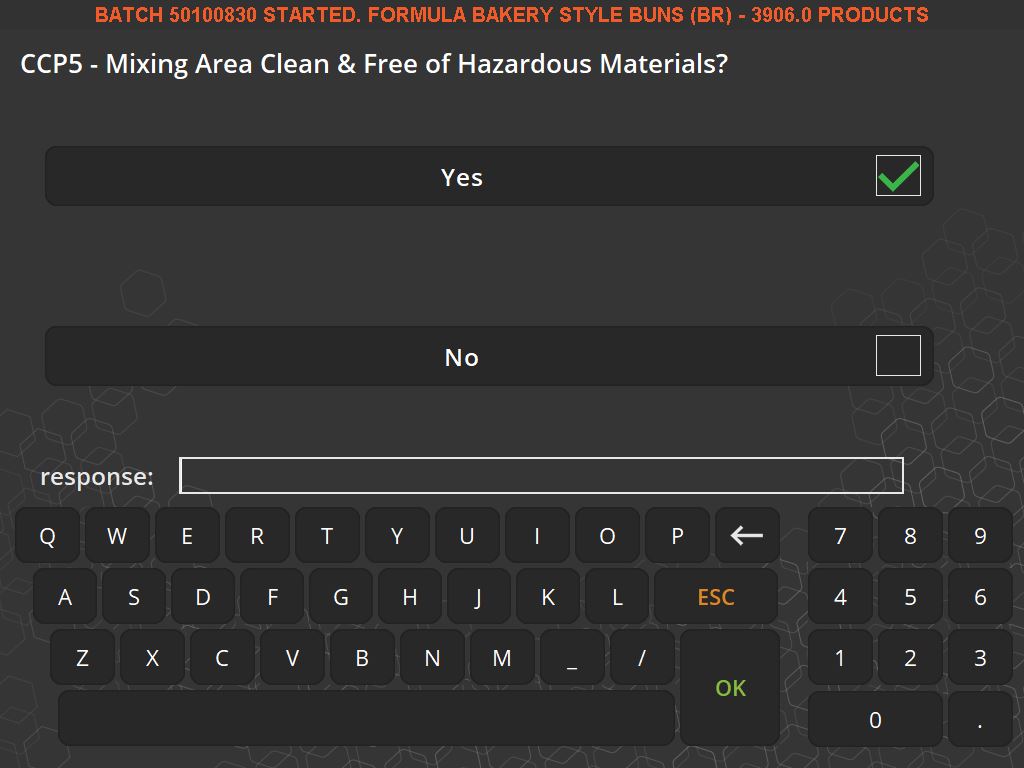

The food manufacturing sector significantly benefits from the integration of NetSuite with SG Systems Global’s V5 Traceability software. This synergy ensures batch consistency, minimizes ingredient wastage, and upholds strict audit compliance standards. The alignment of NetSuite’s ERP capabilities with specialized traceability software provides food manufacturers with unprecedented control and efficiency in their processes.

Paperless Operations and Quick ROI Across Industries:

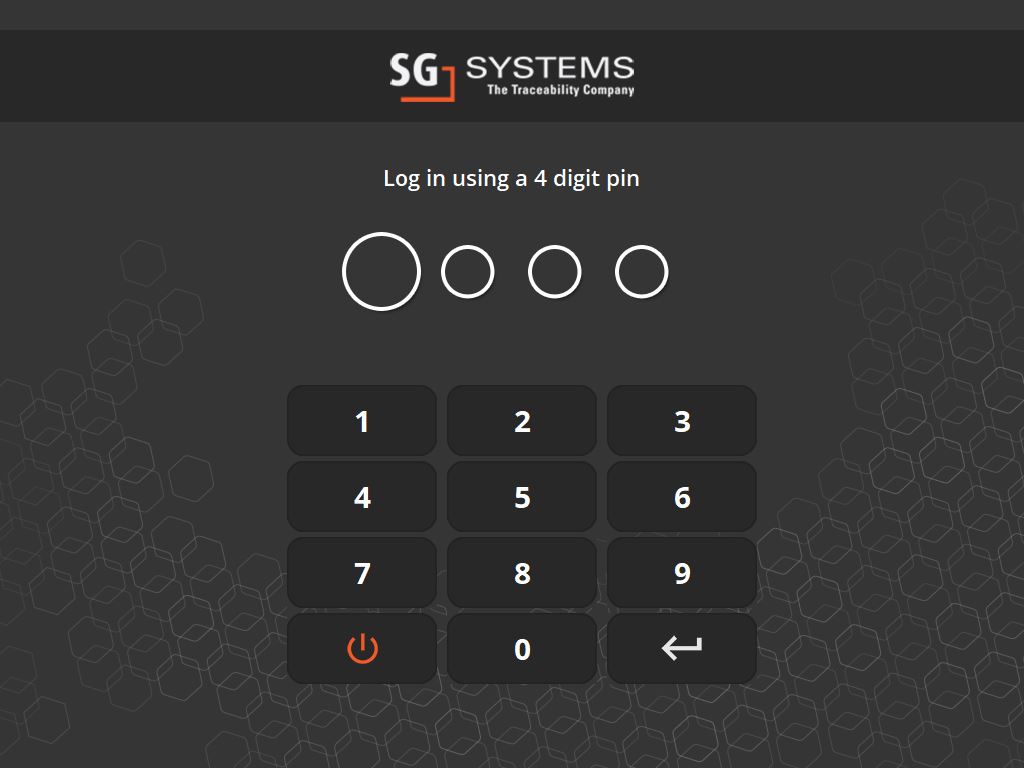

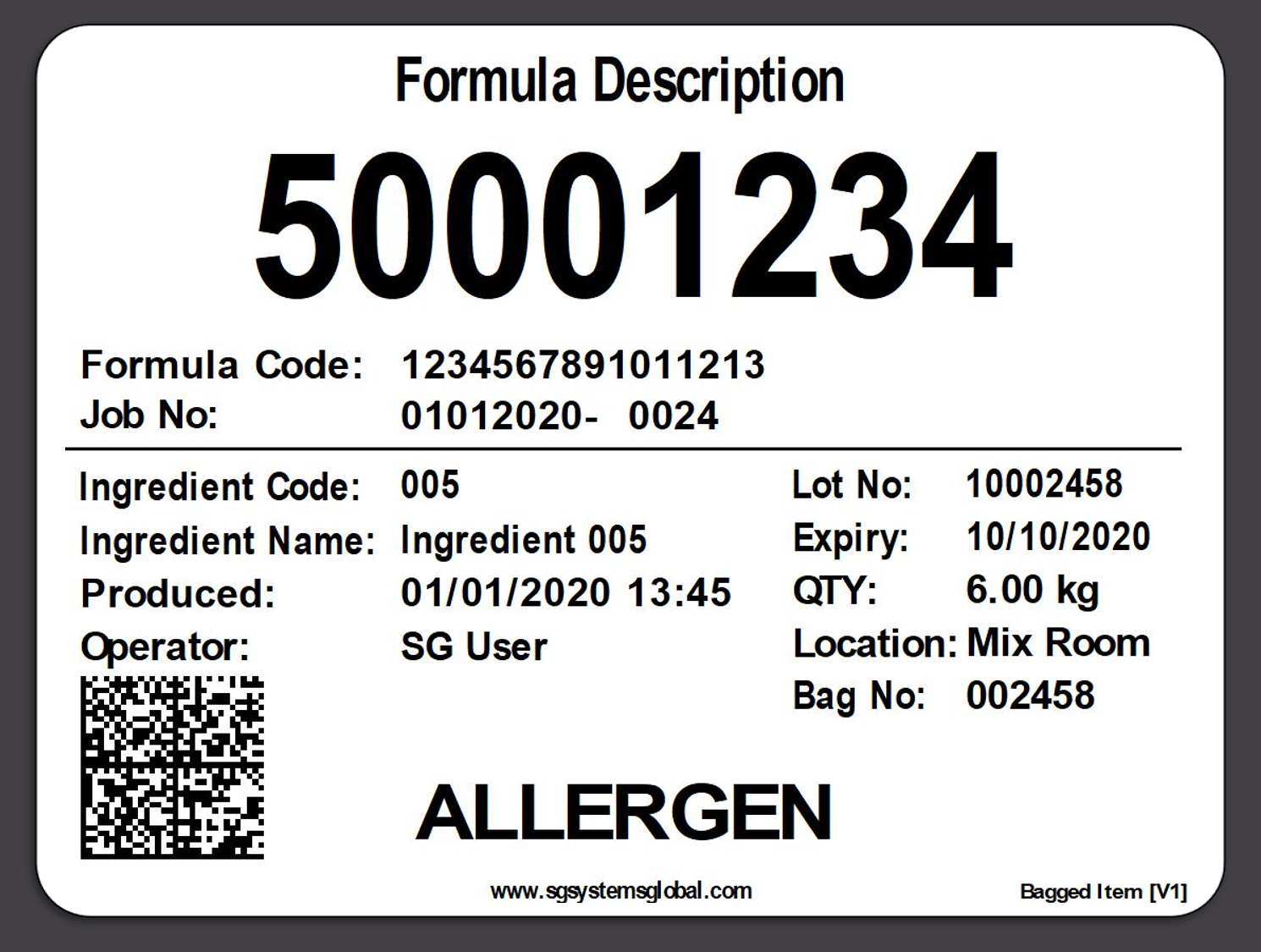

V5 Traceability, a versatile and paperless software solution, perfectly complements NetSuite, offering an essential plugin to existing ERP and accounting systems. Suitable for businesses of all sizes, it facilitates warehouse management and provides a swift return on investment. Companies aiming to modernize their operations find this integration an invaluable tool in achieving operational excellence and traceability.

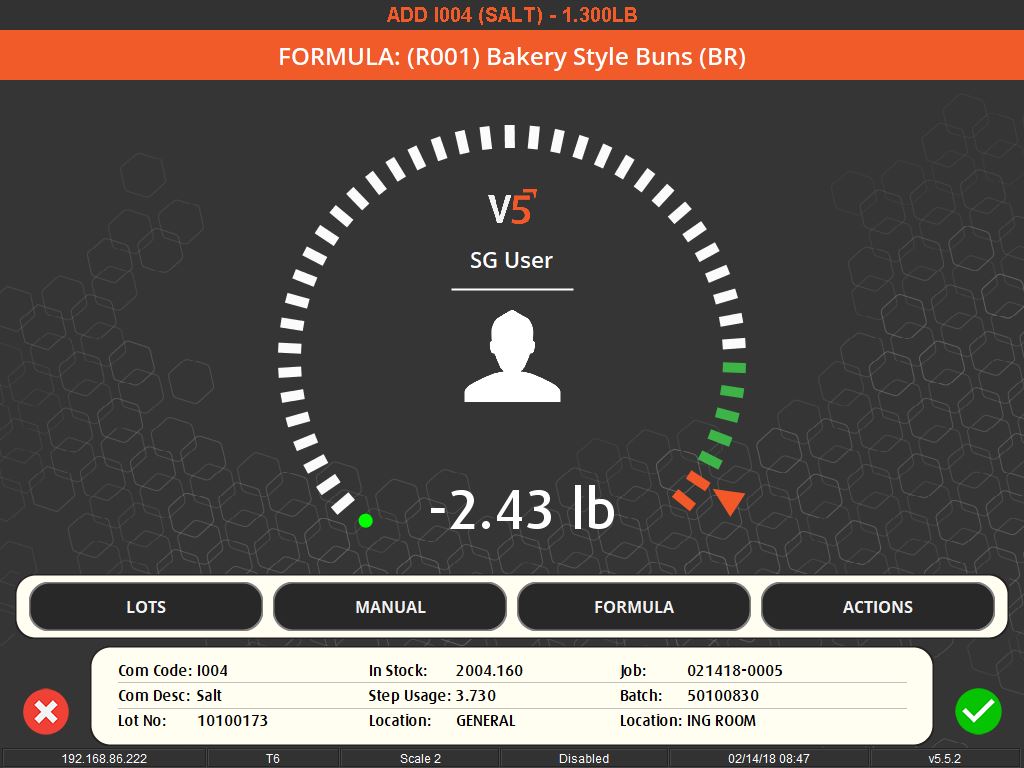

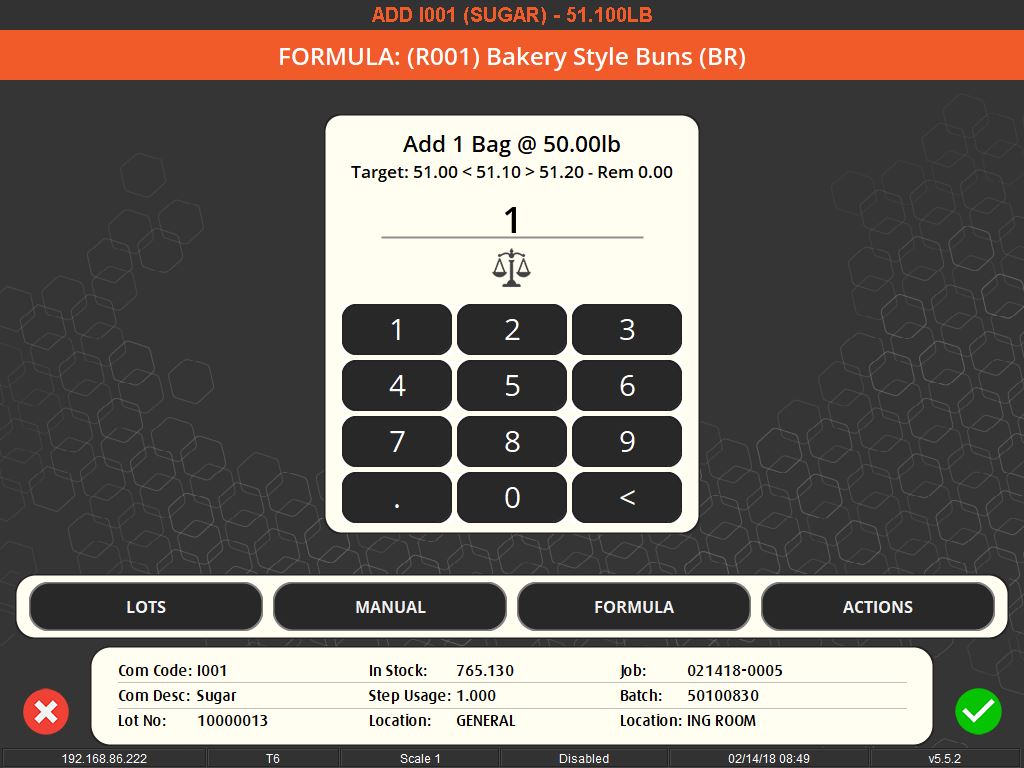

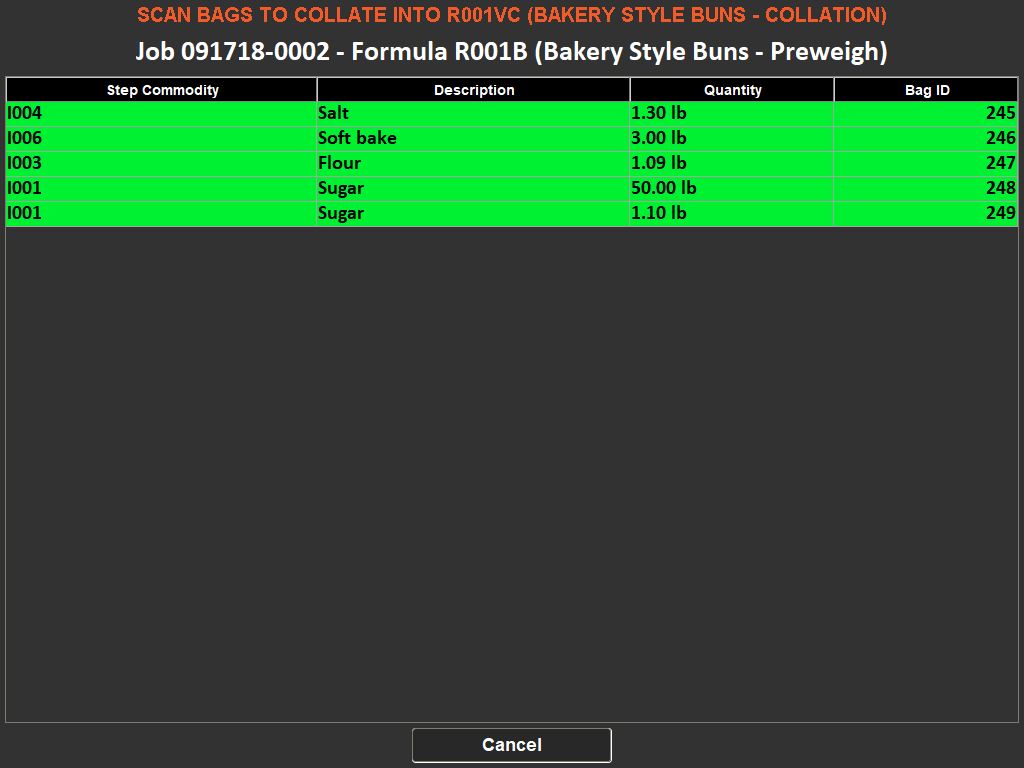

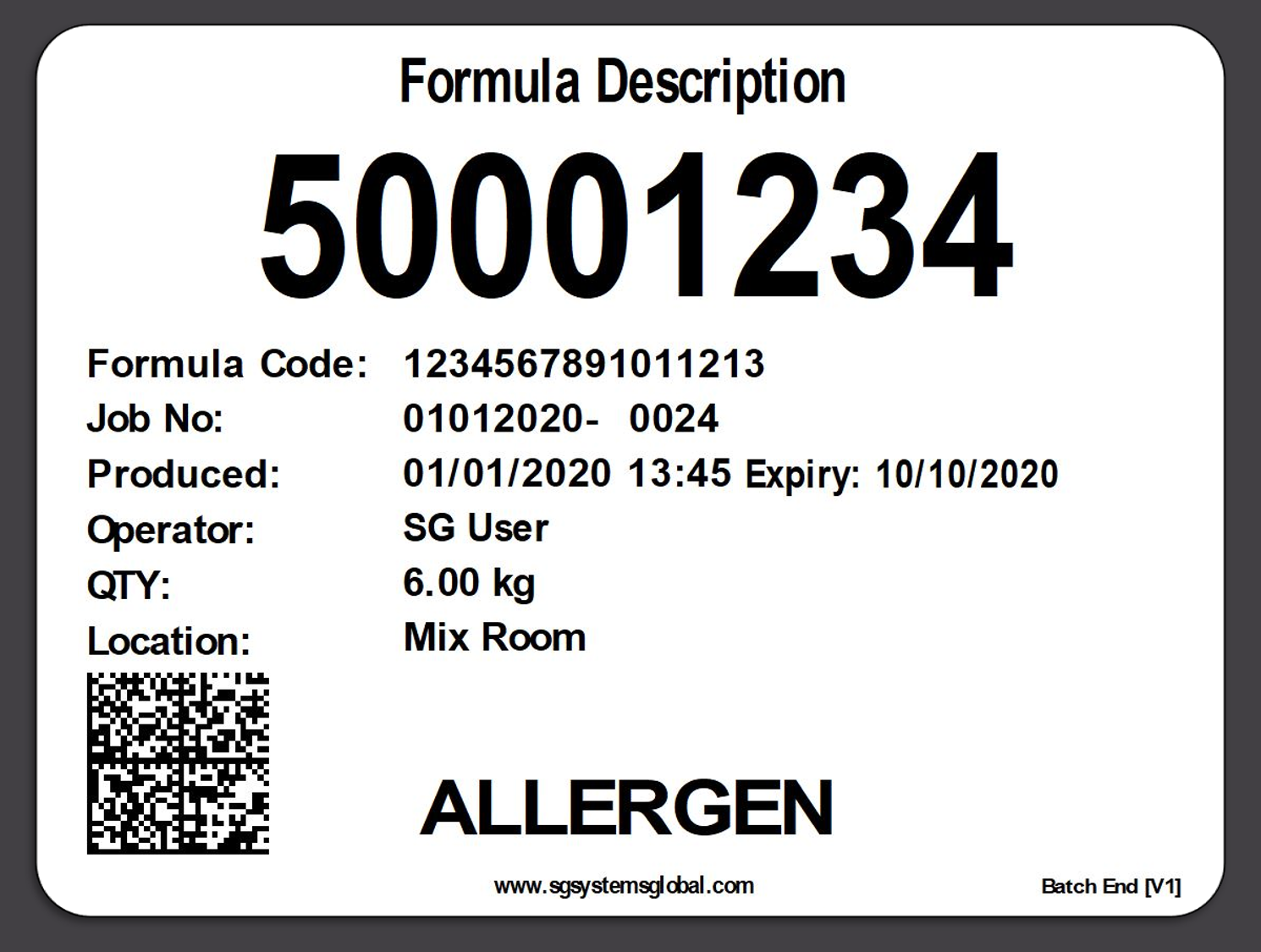

Error Prevention and Data Accuracy Enhancement:

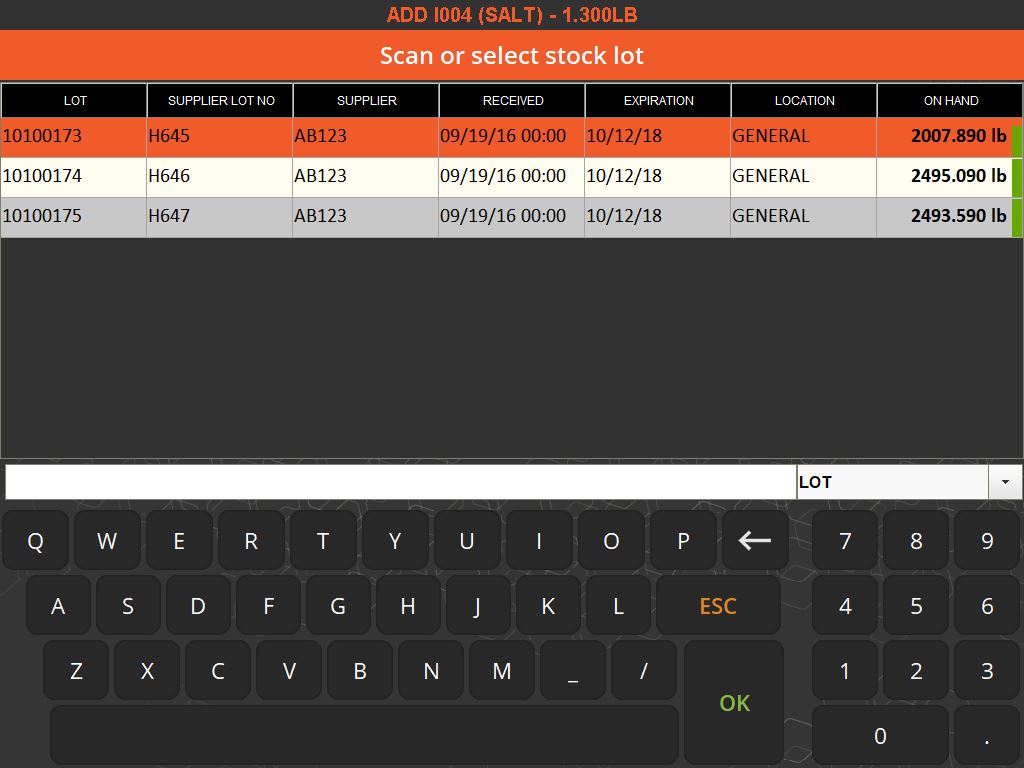

The amalgamation of NetSuite with V5 Traceability effectively addresses the challenges of manual traceability errors. The integration brings in a Gateway module that enhances the accuracy of inventory, production, and order management, thereby eliminating common issues associated with manual processes. This ensures that ERP systems are equipped with accurate and accountable data, preventing losses and inaccuracies.

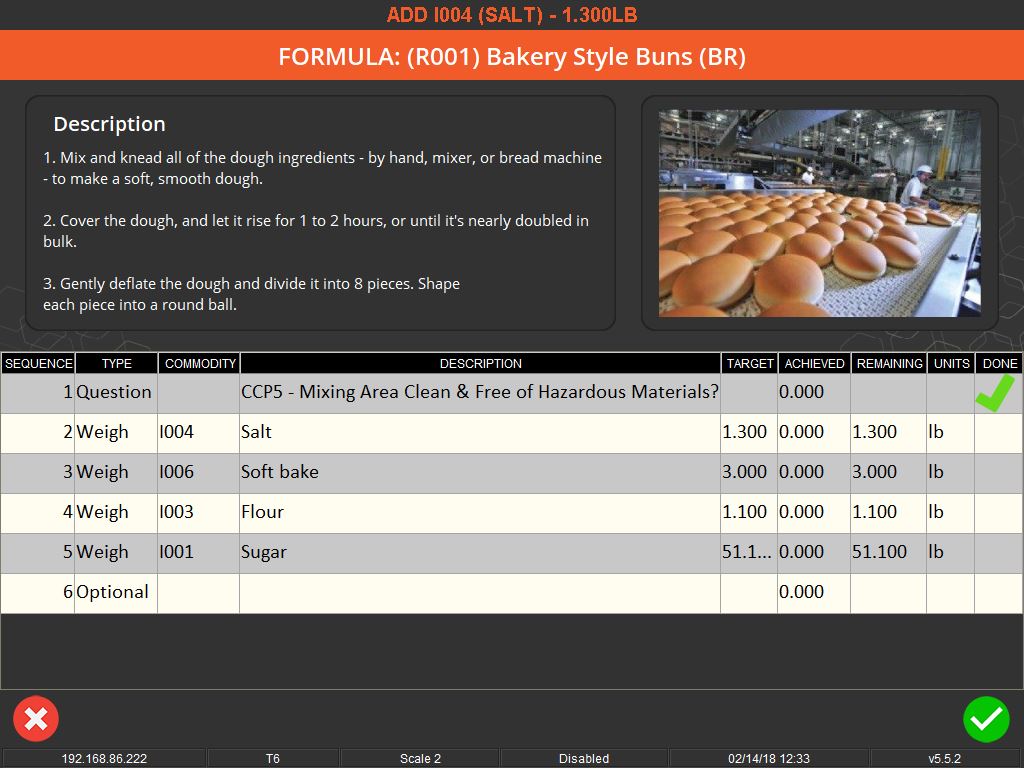

End-to-End Traceability Solutions:

This integration offers comprehensive traceability, including forward and backward tracing capabilities. Ideal for companies needing a single solution to track materials across the entire production cycle, it extends ERP and accounting software functionality. From receiving to shipping, including batching and production processes, businesses can enjoy full traceability and operational oversight.

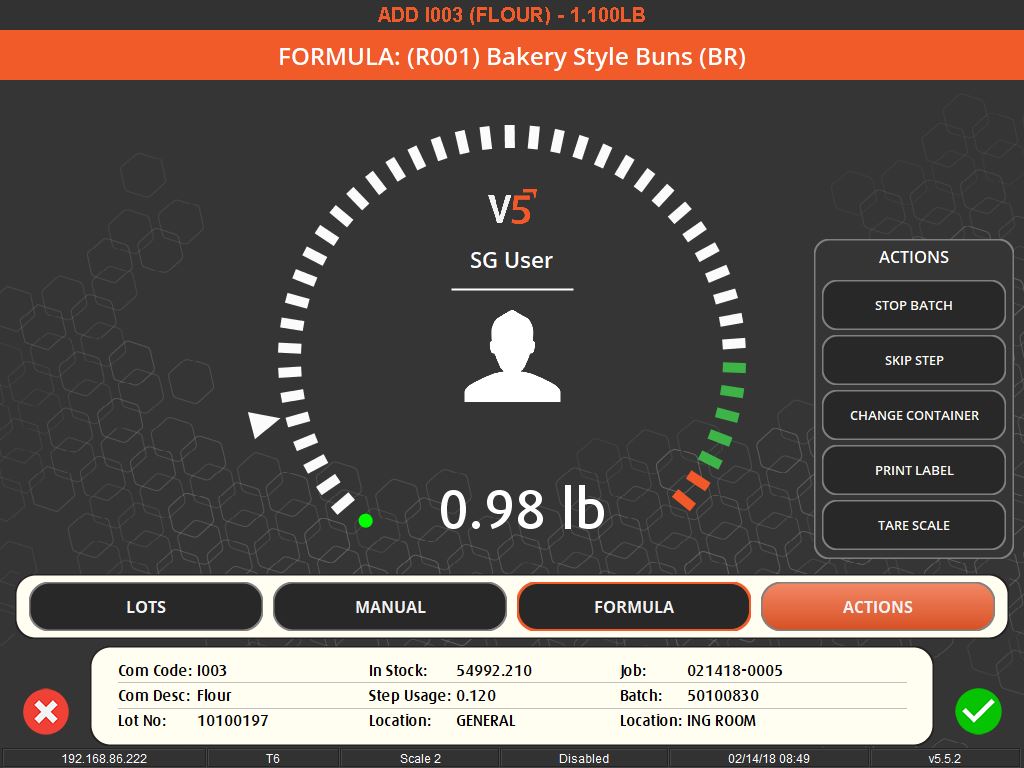

Enhanced Operational Flexibility and Customization:

NetSuite and V5 Traceability’s integration is designed to adapt to various business models and operational needs. Companies can customize the data exchange frequency and the types of data exchanged, allowing for a highly adaptable and flexible system. This ensures that businesses of different scales and industries can leverage the benefits of this integration, tailoring it to their specific needs.

Real-Time Data Access and Decision Making:

The integration empowers businesses with real-time data access, enabling faster and more informed decision-making. This is particularly crucial in dynamic market conditions, where timely information can be the difference between success and failure. Companies can react swiftly to market changes, inventory levels, and production demands, thanks to the instantaneous data flow between NetSuite and V5 Traceability.

Scalable Solutions for Growing Businesses:

As businesses grow, their operational and traceability needs evolve. The integration of NetSuite with V5 Traceability is scalable, catering to the expanding requirements of growing businesses. This scalability ensures that companies can continue to benefit from the integration without the need for significant system overhauls, making it a long-term solution for businesses on a growth trajectory.