V5 Manufacturing Execution System

Manufacturing Execution Systems (MES) are integral to modern manufacturing processes, offering a blend of automation, digitization, and real-time operational control. These systems are designed to manage, monitor, and track the transformation of raw materials into finished products, providing critical insights that enhance performance, reduce costs, and increase production efficiency.

MES functions extend beyond traditional product and process design, working in conjunction with ERP (Enterprise Resource Planning) systems to offer a more comprehensive operational picture. By integrating these systems, manufacturers can make more informed decisions, combining the strategic insights from ERP with the operational guidance of MES.

Key Functions and Benefits of MES include:

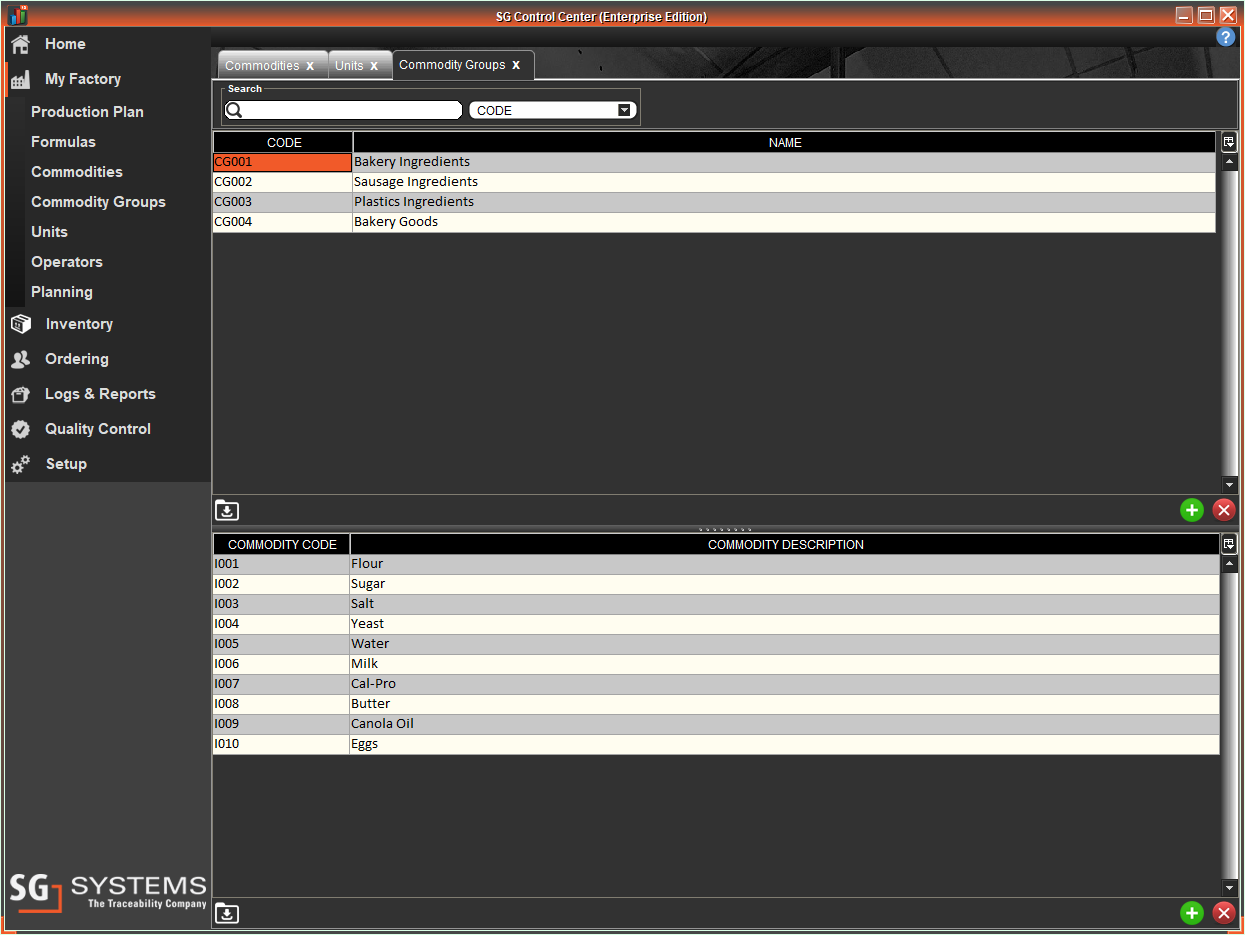

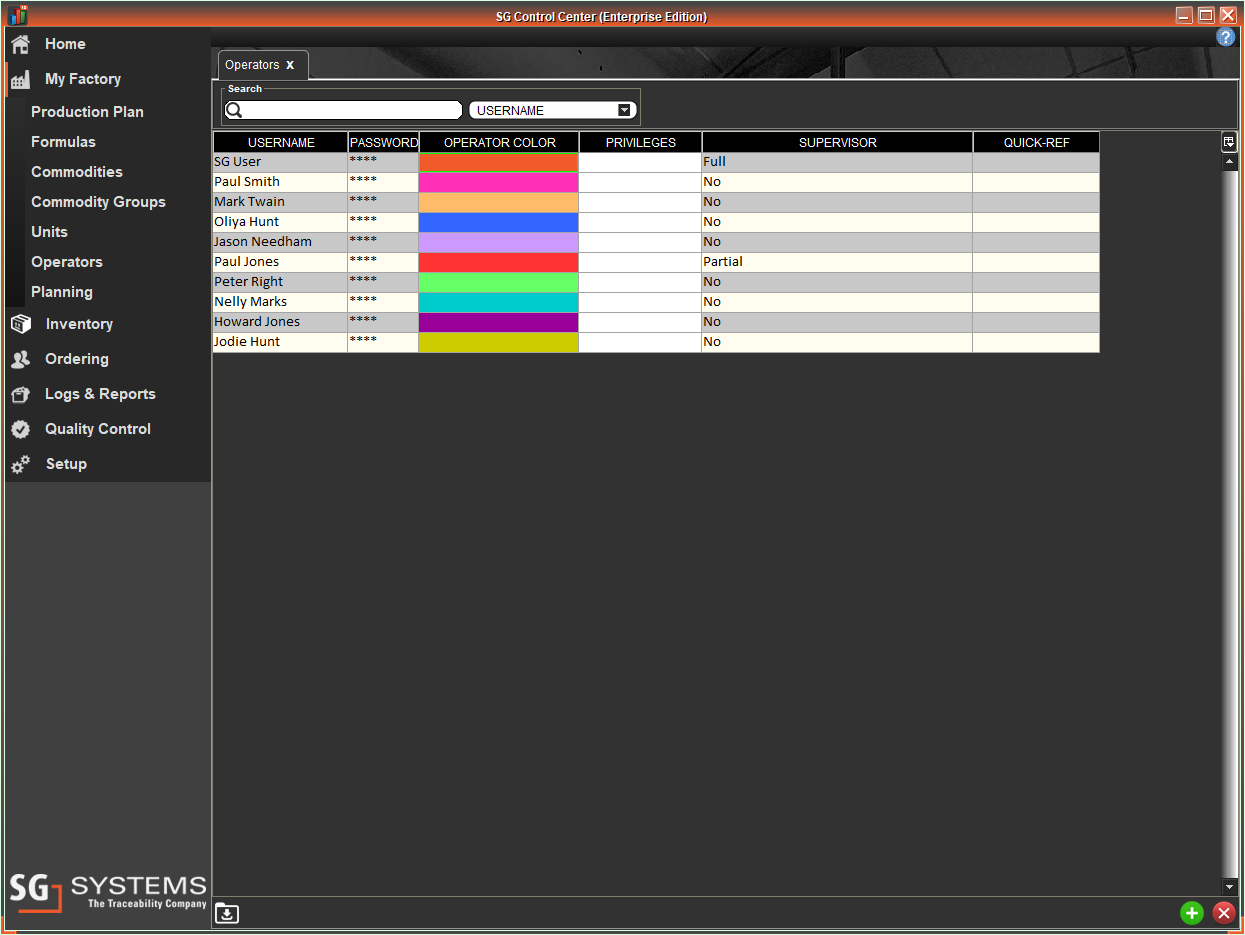

- Allocation and Monitoring of Production Resources: MES systems handle the management of essential production resources, ranging from equipment and tools to the skilled workforce needed for production processes.

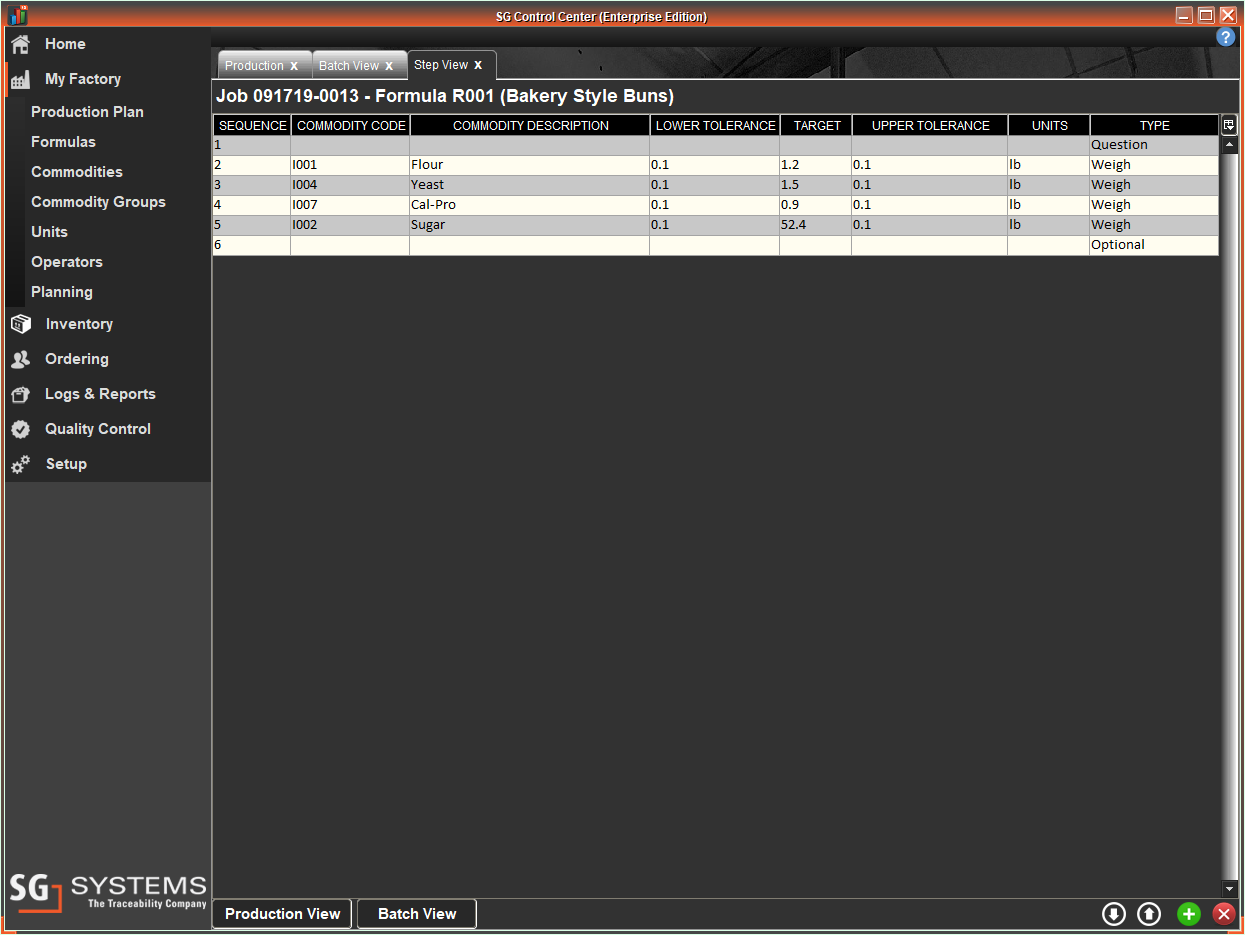

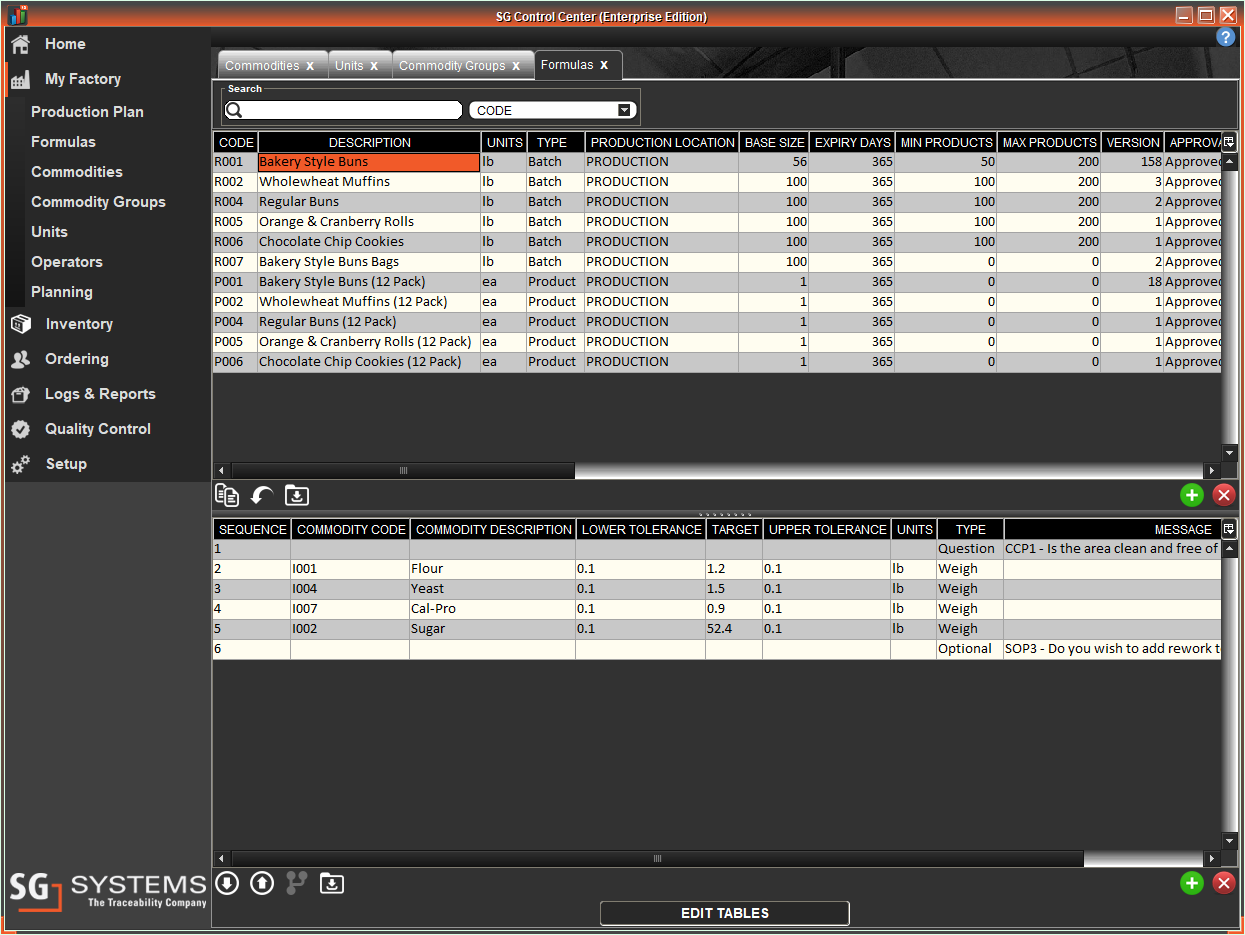

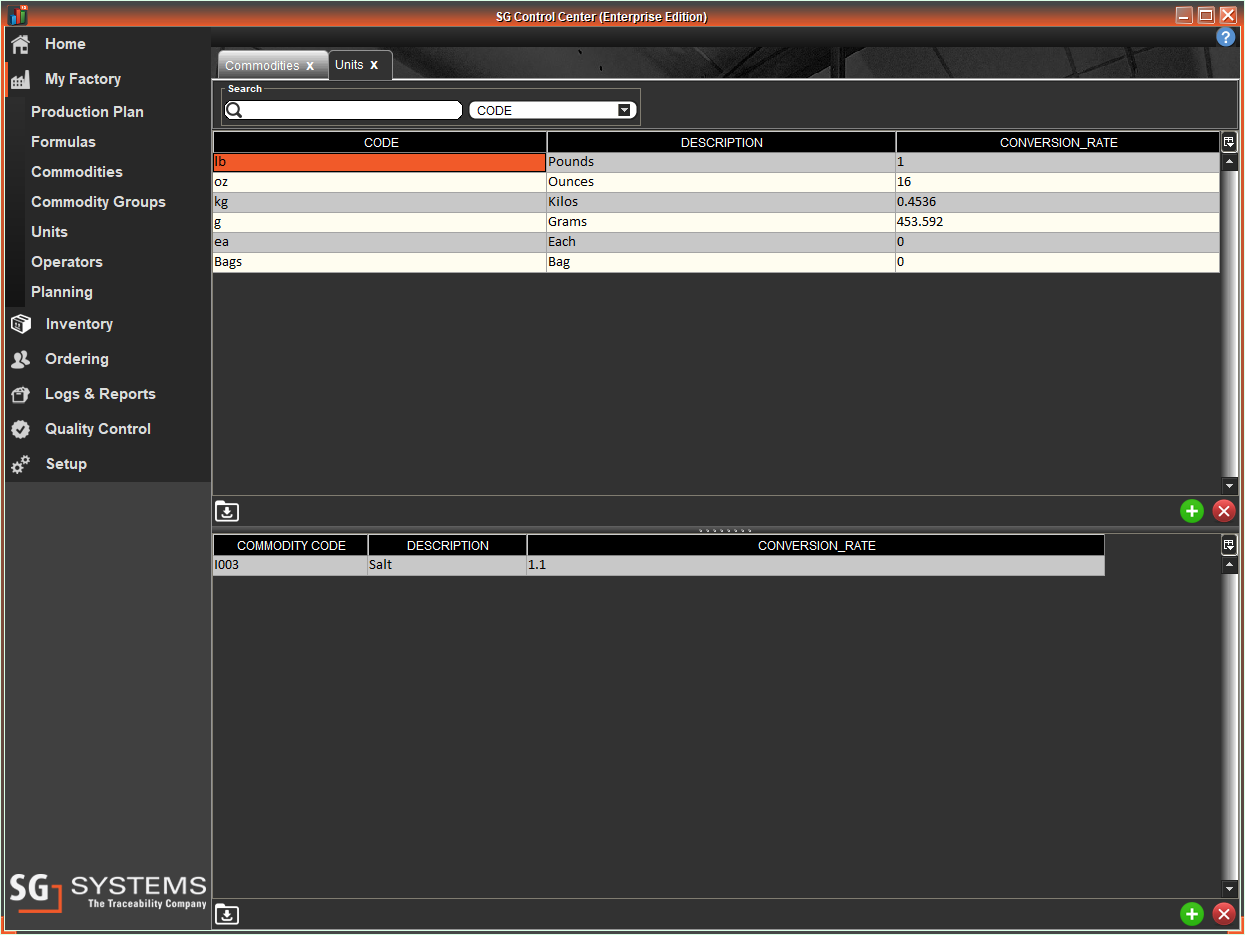

- Management of Specifications and Documents: They efficiently handle essential documents and materials, encompassing work instructions, bills of materials, and design specifications, thereby standardizing processes and reducing the scope for errors.

- Equipment Maintenance Management: MES systems also manage the maintenance and scheduling of facilities and equipment, ensuring operational continuity and reducing downtime.

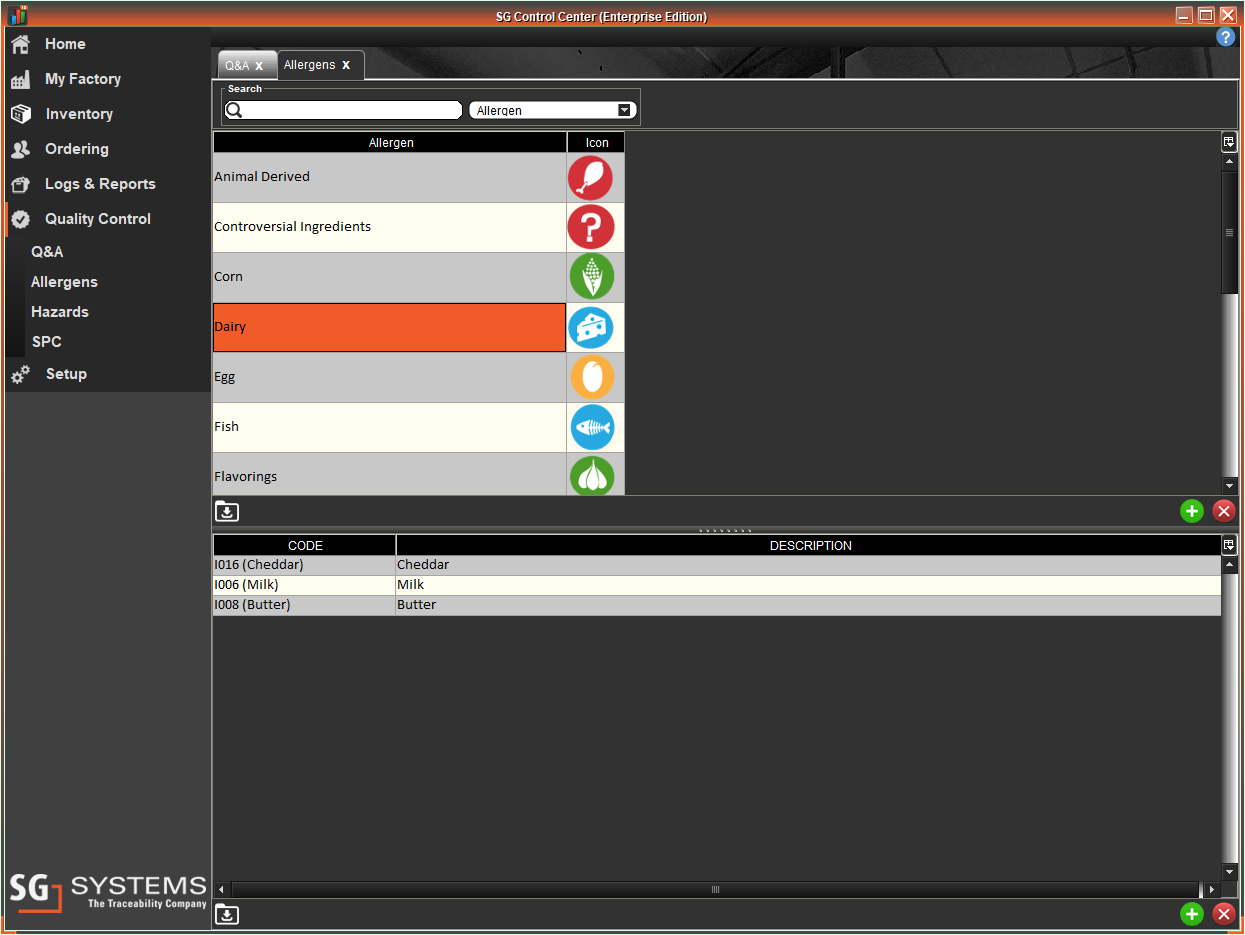

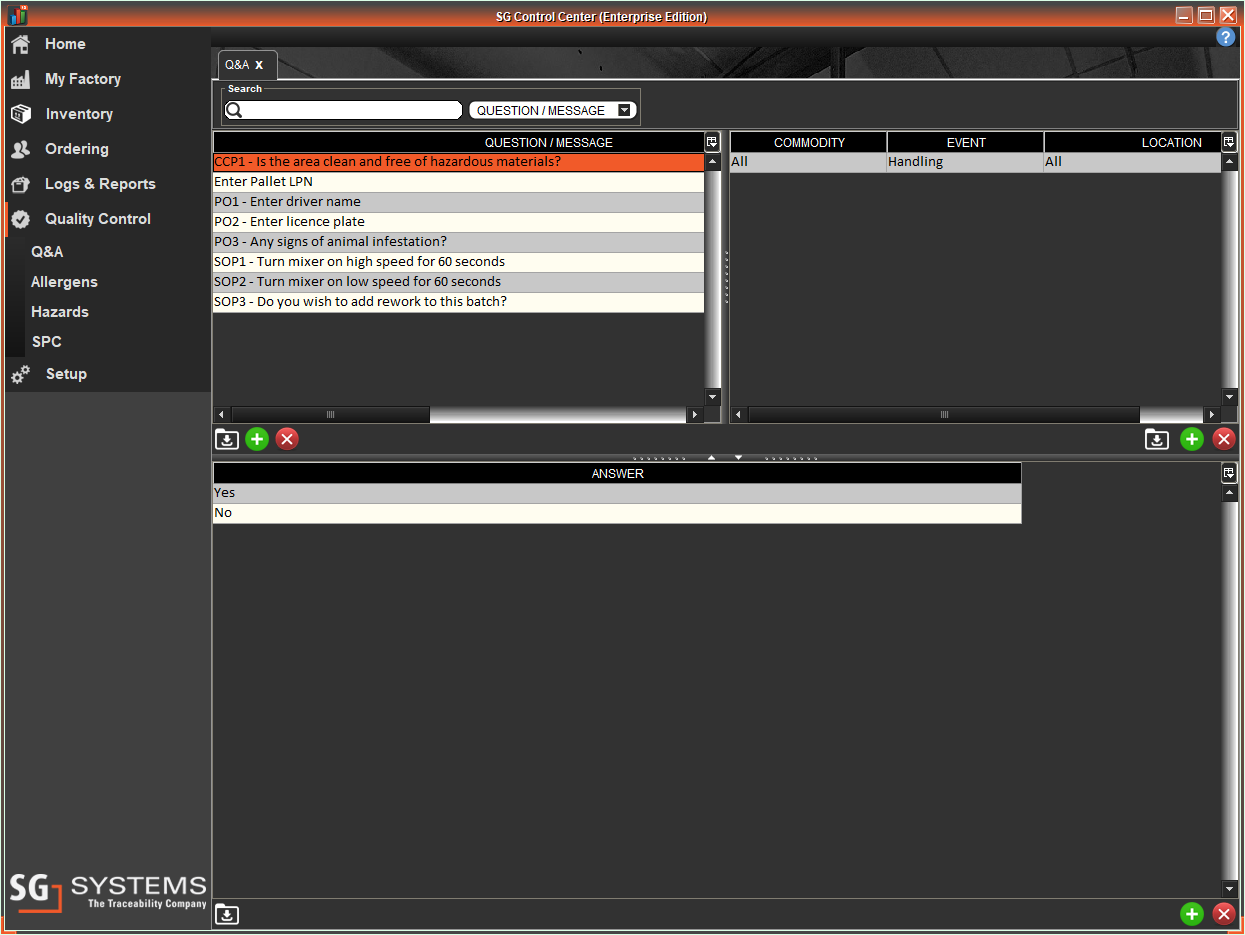

- Product Quality Control: These systems support robust quality control measures based on real-time data collection, ensuring consistent product quality and compliance with regulatory standards.

- Work Schedule Management: MES enables the creation of detailed work schedules based on production plans, including employee assignments and shifts, optimizing the workforce deployment.

- Work Arrangements and Manufacturing Instructions: MES systems issue clear instructions regarding production parameters, helping to streamline manufacturing processes and reduce inefficiencies.

- Worker Placement and Situation Management: They manage the placement and status of workers, ensuring optimal allocation of human resources.

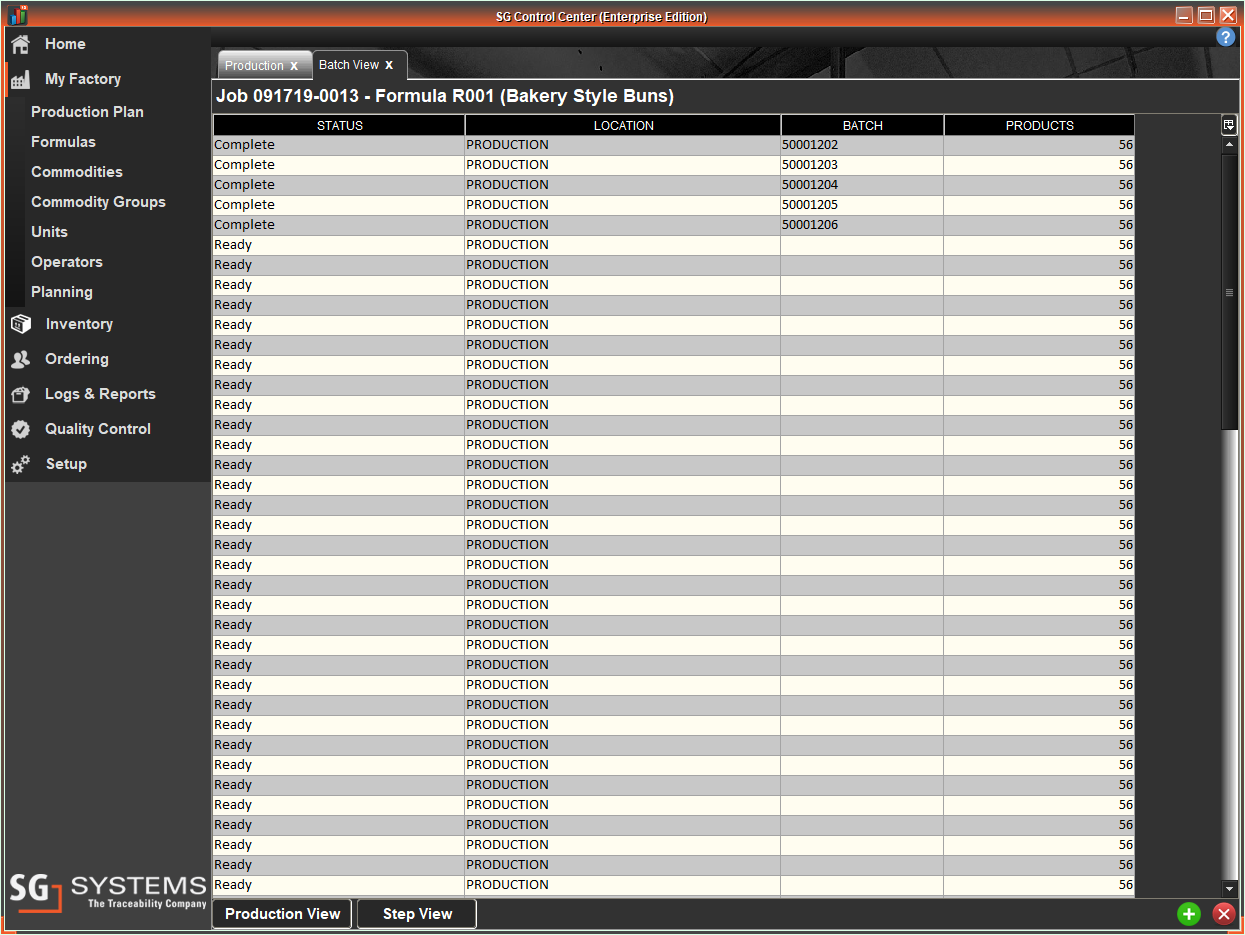

- Collection of Process Data: MES systems collect data for each process, offering real-time visibility into production progress and enabling proactive decision-making.

- Monitoring and Supporting Work Processes: These systems monitor work processes and support work procedures, aiding in operational management and decision-making.

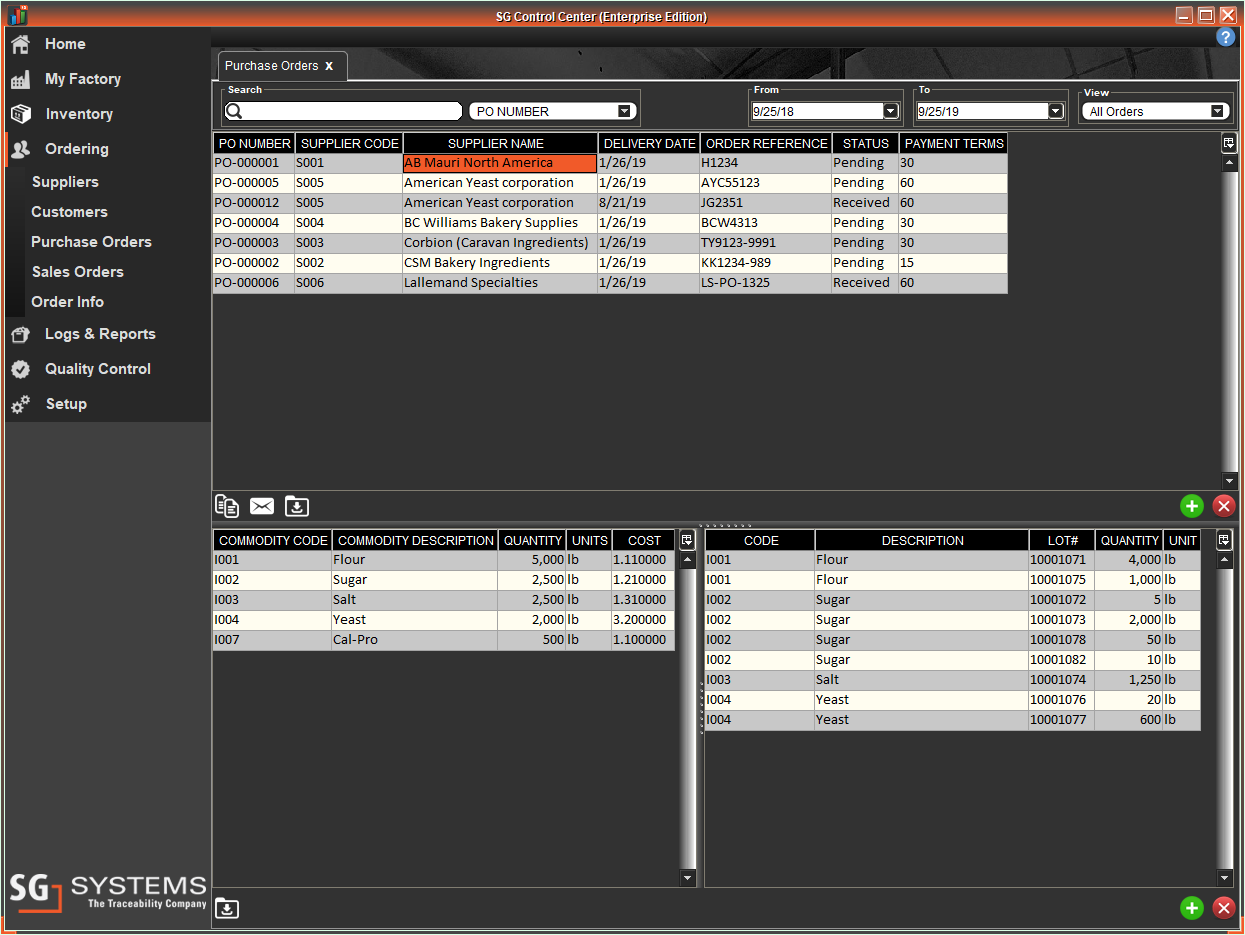

- Product Tracking and System Management: MES offers tracking capabilities for work-in-progress and finished products, aiding in inventory management and product traceability.

- Performance Analysis and Reporting: They analyze and report on production status, offering insights into operational performance and areas for improvement.

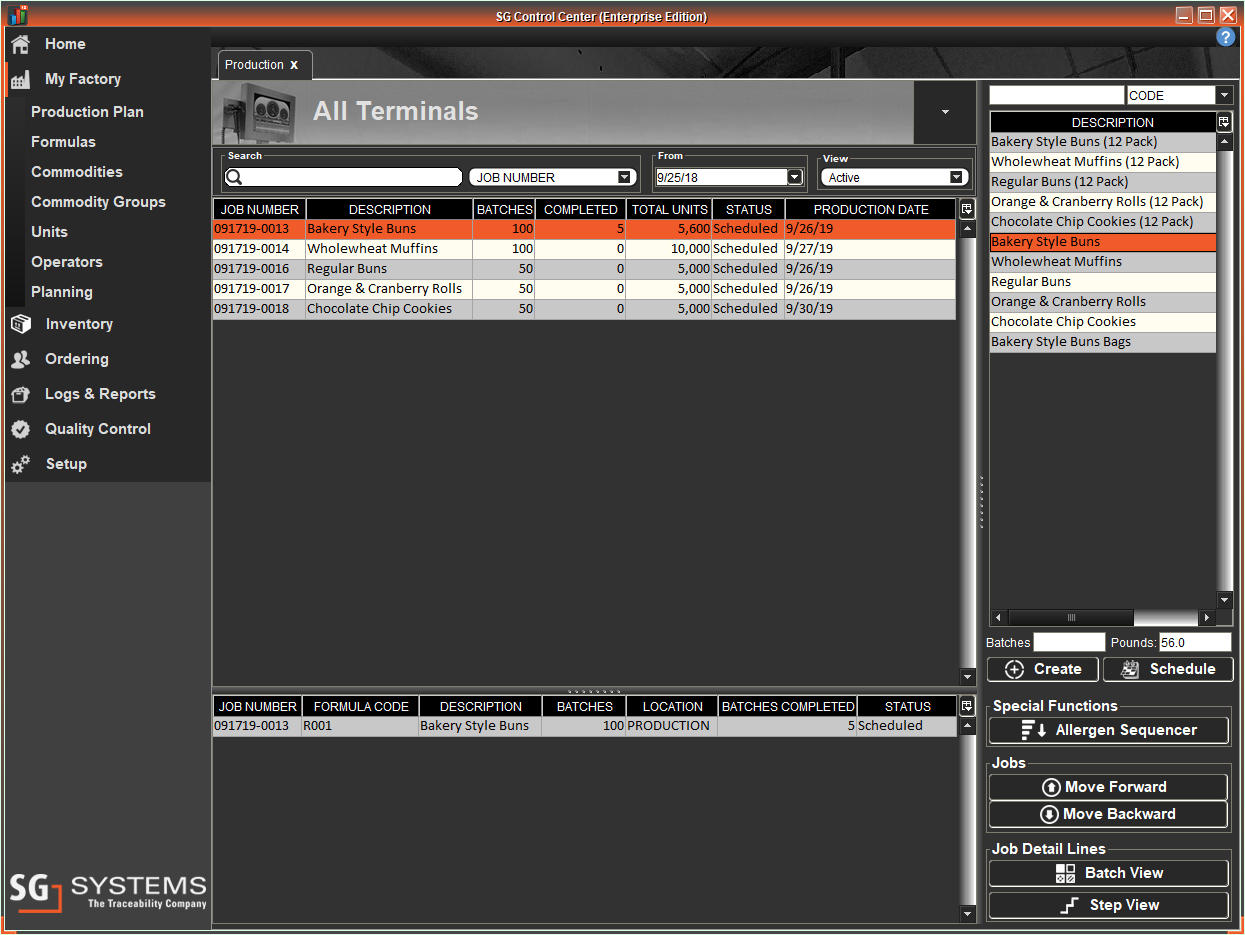

In the context of SG Systems Global’s V5 Control Center Software, it aligns closely with MES functionalities. The software facilitates production scheduling, recipe formulation, inventory control, and purchase and sales order management. With an emphasis on quality assurance and operator controls, it supports the core objectives of MES, including resource allocation, process monitoring, and quality control. The software provides full traceability, a key aspect of MES, tracking materials from receiving to shipping and serving as middleware to extend ERP functionality with real-time production floor data.

Overall, SG Systems Global’s V5 Control Center Software exemplifies the capabilities of an MES, offering a holistic solution for automating and managing manufacturing processes. Its features support the essential functions and benefits of an MES, making it a powerful tool for improving production efficiency, quality control, and operational effectiveness in the manufacturing sector.