News

Warehouse Inventory Transfer Orders

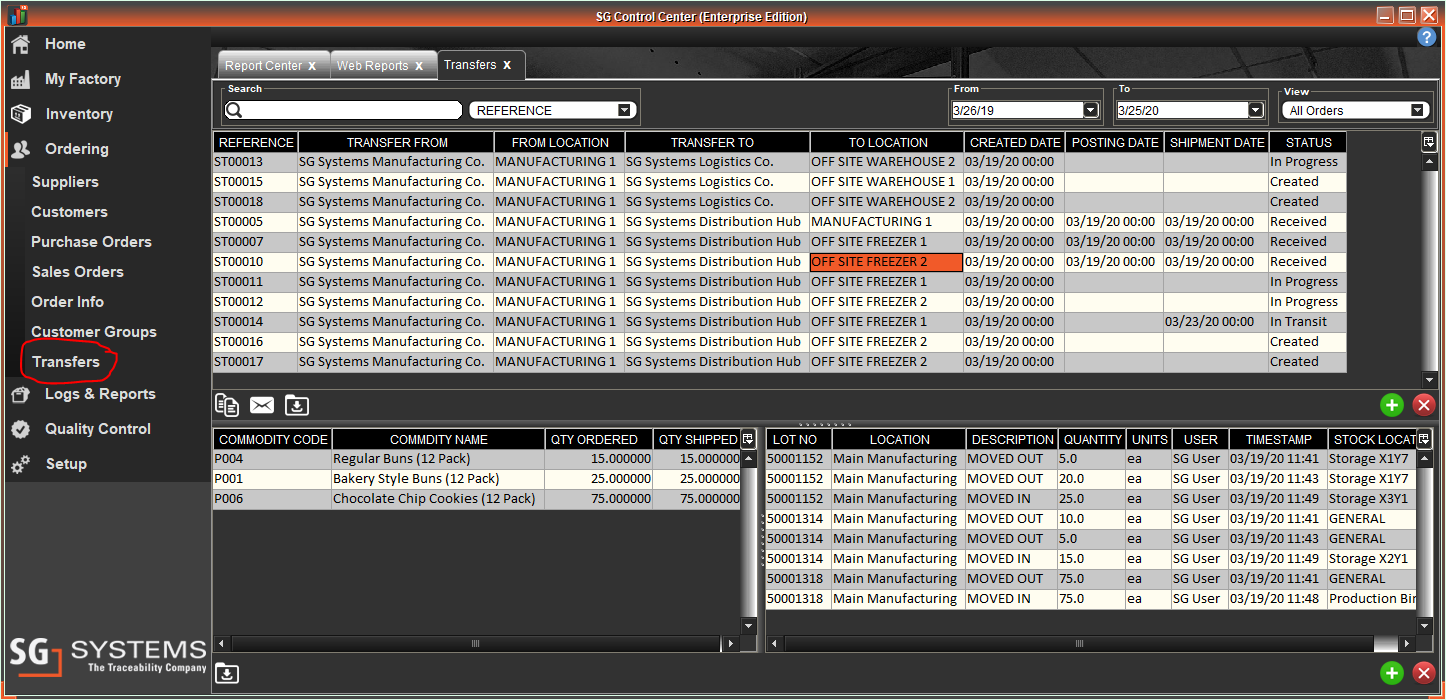

SG Systems is delighted to announce the latest WMS development available as an option in V5 WMS Professional Edition V5.6.69 and above. Warehouse Inventory Transfer Orders (referred to as ‘Transfers” allows companies to schedule inventory movements between locations and manage the ‘IN-TRANSIT’ status to account for the delivery itself.

Stock Transfer

Stock Transfers

Made very simple and intuitive, the Control Center software allows managers to setup Sites, with their respective Stock and Production Locations. After setup, Transfer Orders can be scheduled from Control Center to the WMS application running on a mobile tablet computer with an integrated barcode scanner. A Warehouse Inventory Transfer Orders is a stock movement order placed by management within control center (or imported through Gateway for Enterprise users). It allows management to decide which items need to be shipped to and from a location setup in V5 Control Center.

Transfer Order Pick & Pack

Items scheduled for transit appear on the V5 WMS application. Just like a production schedule, the transit orders appear on a list for the operator to select. Once selected, the items which require moving are listed. Operators are then required to pick inventory and build the transfer order. The usual Warehouse Inventory Transfer Orders rules apply, picked stock must be rotated FEFO or FIFO and within its expiration parameters (this can be overridden by a supervisor). When all items are picked and collected, the order status changes from ‘In Progress’ to ‘In Transit’. During the collection process, operators can be prompted for QA specific data such as trailer number, seal number plus any other user defined QA. A Stock Transfer Report report is now available to accompany the delivery driver.

Transfer Order Receiving

Stock Transfer Tablet PC

Upon arrival at the ‘To’ location, the driver presents the recipient with the Stock Transfer Report. The WMS Operator, then scans the barcode on the report to validate the stock transfer order. The operator can now receive two different ways (defined by management). The first method is to receive item by item, confirming the quantity of each item and lot – in other words, verifying that all items are present. The second method requires less verification – the operator simply confirms all items are present. Both methods now update the status to ‘Received’. Once the items are received, they can be put-away into their respective stock location using the rack aisle, row and column nomenclature and put-away rules defined by management. To complete the transaction a Stock Transfer Received Report confirms all stock movements for traceability and accountability.

Inventory Management

The above Warehouse Inventory Transfer Orders process allows management to accurately locate inventory in a busy logistics environment. Goods missing in transit can be quickly identified at the source and the transit process is fast, accurate and simple to operate. Comprehensive reporting allows managers to see where goods are located, their freshness and which items potentially need to be moved to a frozen or refrigerated environment. The above process reduces error and is proven to pay for itself in administration alone.

for more info contact [email protected]

North America

SG Systems LLC

4101 McEwen #240, Dallas TX 75244

Phone: +1 214 819 9570

Contact us here

United Kingdom

SG Systems Europe Ltd

Suite 3 Walton Summit Centre, Green Place, Four Oaks Rd, Preston, PR5 8AY

Phone: +44 (0) 114 349 1480

Contact us here

Australia

Wedderburn

101 Williamson Road, Ingleburn NSW 2565

Phone: +61 2 9426 1800

Contact us here

Europe

SG Traceability Systems Ltd

31-32 Greenmount Office Park, Harolds Cross, Dublin D6, Ireland

Phone: +44 (0) 114 349 1480

Contact us here

Rest assured, we value your privacy and are committed to keeping your data safe. By clicking "Continue with recommended settings," you're giving us permission to use cookies. Of course, you're in control – feel free to adjust your cookie settings anytime in our Privacy Preferences.