- Home

- Cycle Counting

- Inventory Cycle Count Software

Cycle Counting

Inventory Cycle Count Software

The perfect enhancement to the V5 Warehouse Management System (WMS), ‘Inventory Cycle Count Software System’ allows Management to decide what and when inventory items are checked for accuracy (Scheduled Cycle Counting). Confirming theoretical inventory with actual inventory is necessary to align internal systems.

Many companies Cycle Count all their inventory or a periodic basis, whether it’s daily, weekly, monthly or annually to achieve financial accuracy.

![]()

Cycle Counting (or Stock Taking) allows management to understand what’s physically on hand, what the systems have on hand and where the discrepancies exist between the two systems.

Scheduled Cycle Counting

V5 Inventory Cycle Count Software System is a unique warehousing management system (WMS) because it considers all received inventory (Bags, bulk etc), then automatically reduces it (perpetual inventory) using scales & meters commonly used in production for batching (See Formula Control for details). Automatically driving down inventory levels from production is the most efficient method of managing inventory and ensuring accurate and validated traceability.

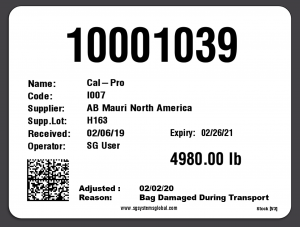

The problem with traditional Inventory Cycle Count Software System is that it takes to much time to physically do it. Operators are typically instructed to check all inventory items, regardless of whether it’s been used in production or not since the last time the item was checked. Inventory labels can be auto printed to detail where items have been adjusted, stating the reason as in the example below.

V5 Inventory Cycle Count Software System uses a sophisticated algorithm to help managers schedule cycle counting based on what’s been used in production since the last cycle count and which are the most expensive items on hand. V5 Cycle Count ensure each inventory item is counted at lease once a quarter (or whichever period you define) to fulfill GMP requirements. In other words, you are only checking what’s important and likely to have discrepancies.

The Result – Fewer Inventory Errors, Less Cycle Counting = Increased Profitability

ERP & Accounting Integration

V5 Cycle Count features a very user friendly and simple to use Warehouse Management WMS interface. The software runs on Windows 10 wireless tablet computers which utilize barcode readers to make the tasks faster and more reliable. It can also run on desktop PC’s or Industrial Terminals depending on your environmental requirements.

Typically V5 Inventory Cycle Count Software System exchanges data with existing ERP or Accounting Systems in real time, as such systems are not normally operator friendly and expose management to risk by exposing such systems to the shop floor. In a normal implementation, V5 Gateway exchanges data on purchase orders, sales orders, item masters, stock locations (rack, rows, bins aisles, proximity etc), allergens and even cycle counting schedules. V5 Gateway then handles these functions safely and returns updates to the ERP System in real time.

Cycle Counting Reporting

Any Cycle Counting that takes place will allow the user to generate a report on the activity. The Cycle Count Report details all inventory items with their respective lots, together with their previous value and new updated values. ‘Reasons’ are captured for the adjustments (which are management defined). Costing data allows management to see the new adjusted values and any positive or negative gains. Hyperlinked lots allow forward traceability reporting of any cycle counted lot to allow management to see exactly where in production the lots have been used.

Cycle Count FAQ’s

- What is a cycle count in a warehouse? A cycle count in a warehouse is a method of inventory auditing where a small subset of inventory is counted on a specific day without counting the entire inventory.

- How does a cycle count system improve inventory accuracy? A cycle count system improves inventory accuracy by frequently checking stock levels, identifying discrepancies quickly, and minimizing disruptions caused by full inventory counts.

- What are the benefits of cycle counting inventory? The benefits of cycle counting inventory include improved accuracy, less disruption to operations, and the ability to identify and correct errors more promptly.

- Can scheduled cycle counting integrate smoothly into daily operations? Yes, scheduled cycle counting can be seamlessly integrated into daily operations by planning counts during slower business periods and using real-time data to inform count schedules.

- What features are important in cycle count software? Important features in cycle count software include real-time data updates, easy integration with existing systems, user-friendly interfaces, and robust reporting tools.

- How does inventory cycle count software facilitate real-time stock management? Inventory cycle count software facilitates real-time stock management by providing up-to-date information on stock levels, enabling quick decision-making, and reducing the chances of stockouts or overstock.

- What are the best practices for implementing a cycle count software system? Best practices for implementing a cycle count software system include training staff thoroughly, starting with a pilot program, setting clear objectives, and regularly reviewing performance metrics.

- How can cycle count in warehouse operations reduce the need for full counts? Cycle count in warehouse operations can reduce the need for full counts by maintaining accurate inventory records through frequent, smaller counts, thus identifying and resolving issues promptly.

- What is the role of cycle count system reports? The role of cycle count system reports is to provide insights into inventory accuracy, highlight trends, and support strategic decisions about stock levels and reorder points.

- Can cycle counting inventory identify discrepancies faster? Yes, cycle counting inventory can identify discrepancies faster because it is done more frequently and focuses on smaller sections of inventory, making it easier to spot and rectify errors.

- How does scheduled cycle counting contribute to lean inventory? Scheduled cycle counting contributes to lean inventory by ensuring that stock levels are kept at optimal levels, reducing waste and ensuring that capital is not tied up in excess inventory.

- Is cycle count software capable of integrating with other systems? Most modern cycle count software is capable of integrating with other warehouse management systems (WMS) and enterprise resource planning (ERP) systems, allowing for streamlined operations.

- What kind of training is required for inventory cycle count software? Training for inventory cycle count software typically involves learning how to navigate the software, understanding best practices for counting, and knowing how to analyze reports generated by the system.

- How does cycle count software system support audit trails? A cycle count software system supports audit trails by logging all counting activities, changes, and adjustments made, providing accountability and traceability for inventory changes.

- What is the impact of cycle counting on order fulfillment? The impact of cycle counting on order fulfillment is generally positive, as it ensures inventory data is accurate, thereby reducing errors in picking and shipping orders.

- How often should inventory cycle count software be used? The frequency of using inventory cycle count software depends on the size of the inventory, the rate of turnover, and the criticality of certain items; it can range from daily to weekly or monthly.

- Can cycle count software help with forecasting and planning? Yes, cycle count software can help with forecasting and planning by providing accurate inventory levels and usage rates, which are essential for making informed purchasing and production decisions.

- What are the challenges of implementing a cycle count software system? Challenges of implementing a cycle count software system include ensuring data accuracy, training employees, integrating with existing systems, and adapting business processes to the new system.

- How does cycle counting affect warehouse efficiency? Cycle counting can greatly improve warehouse efficiency by reducing the downtime associated with full inventory counts and enabling more accurate and efficient picking processes.

What metrics can be used to measure the success of inventory cycle count software? Metrics to measure the success of inventory cycle count software include improvements in inventory accuracy, reductions in out-of-stock incidents, and increased efficiency in warehouse operations.

Interested in scheduling and tracing stock between multiple site locations? click here.

More details on the Inventory Cycle Counting Software System can be found on the V5 WMS page or by contacting SG Systems at [email protected]

North America

SG Systems LLC

4101 McEwen #240, Dallas TX 75244

Phone: +1 214 819 9570

Contact us here

United Kingdom

SG Systems Europe Ltd

Suite 3 Walton Summit Centre, Green Place, Four Oaks Rd, Preston, PR5 8AY

Phone: +44 (0) 114 349 1480

Contact us here

Australia

Wedderburn

101 Williamson Road, Ingleburn NSW 2565

Phone: +61 2 9426 1800

Contact us here

Europe

SG Traceability Systems Ltd

31-32 Greenmount Office Park, Harolds Cross, Dublin D6, Ireland

Phone: +44 (0) 114 349 1480

Contact us here

Rest assured, we value your privacy and are committed to keeping your data safe. By clicking "Continue with recommended settings," you're giving us permission to use cookies. Of course, you're in control – feel free to adjust your cookie settings anytime in our Privacy Preferences.